Analysis of explosion resistance of the blast wall with negative Poisson’s ratio Structure

-

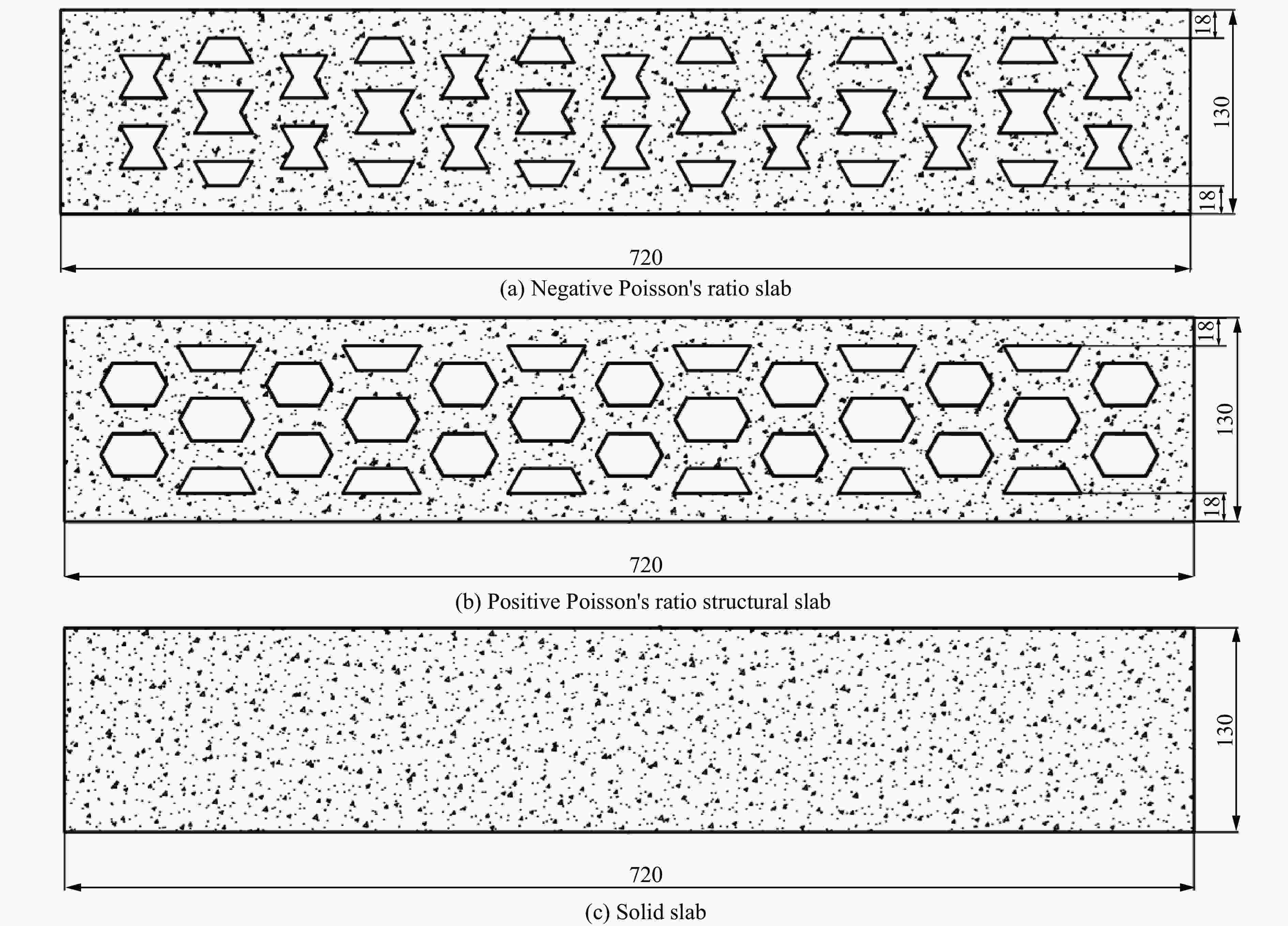

摘要: 为提升防爆墙的抗爆性能,将负泊松比结构与超高韧性水泥基复合材料(ultra-high toughness cementitious composites, UHTCC)结合,并通过爆炸试验与数值模拟相结合的方法,研究分析负泊松比靶板的抗爆性能,证明UHTCC负泊松比靶板的抗爆性能优越性。首先,利用混凝土3D打印技术实现负泊松比结构建造,并通过靶板接触爆炸试验结果验证有限元模型的可靠性。在此基础上,利用该有限元模型模拟分析了靶板材料、结构、胞元内凹角及实心层厚度占比等因素对接触爆炸下结构破坏形态与能量消耗的影响。结果表明:(1)具有高韧性的UHTCC靶板抗爆性能显著优于混凝土靶板;(2)3种结构中,负泊松比结构板吸能能力最强,实心板更能保持结构的完整性;(3)当负泊松比胞元内凹角为61°时抗爆性能最优,过小或过大均降低结构抗爆性;(4)负泊松比结构厚度占靶板总厚度过大时抗爆性能弱,结构破坏严重,可上下层同时或仅背爆面增加实心层厚度,在有效削弱爆炸冲击波、吸收能量的同时,提高结构完整性。研究验证了负泊松比UHTCC板抗爆性能优越性,并为基于负泊松比结构的防爆墙设计提供了理论依据。

-

关键词:

- 负泊松比结构 /

- 超高韧性水泥基复合材料 /

- 爆炸荷载

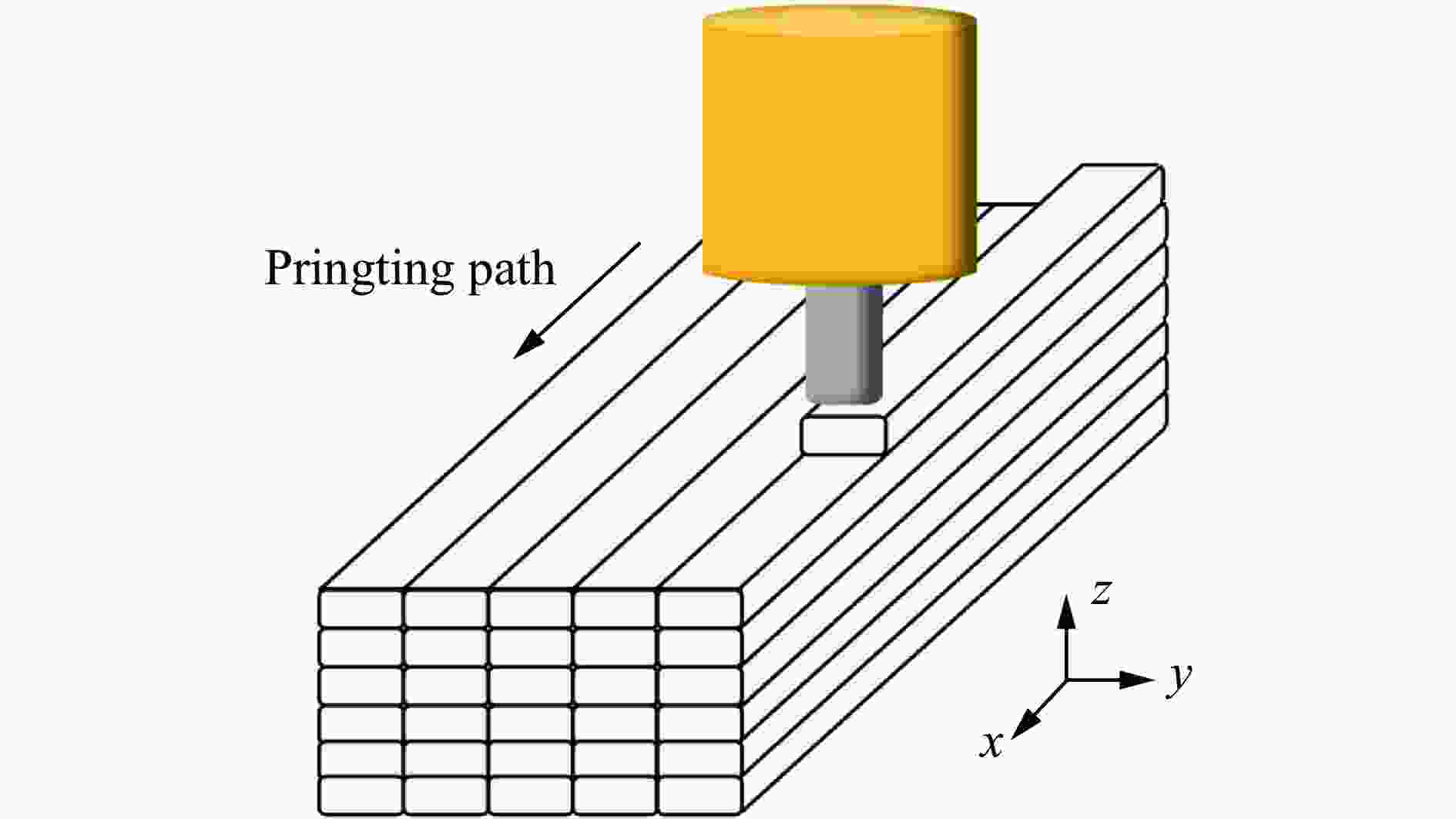

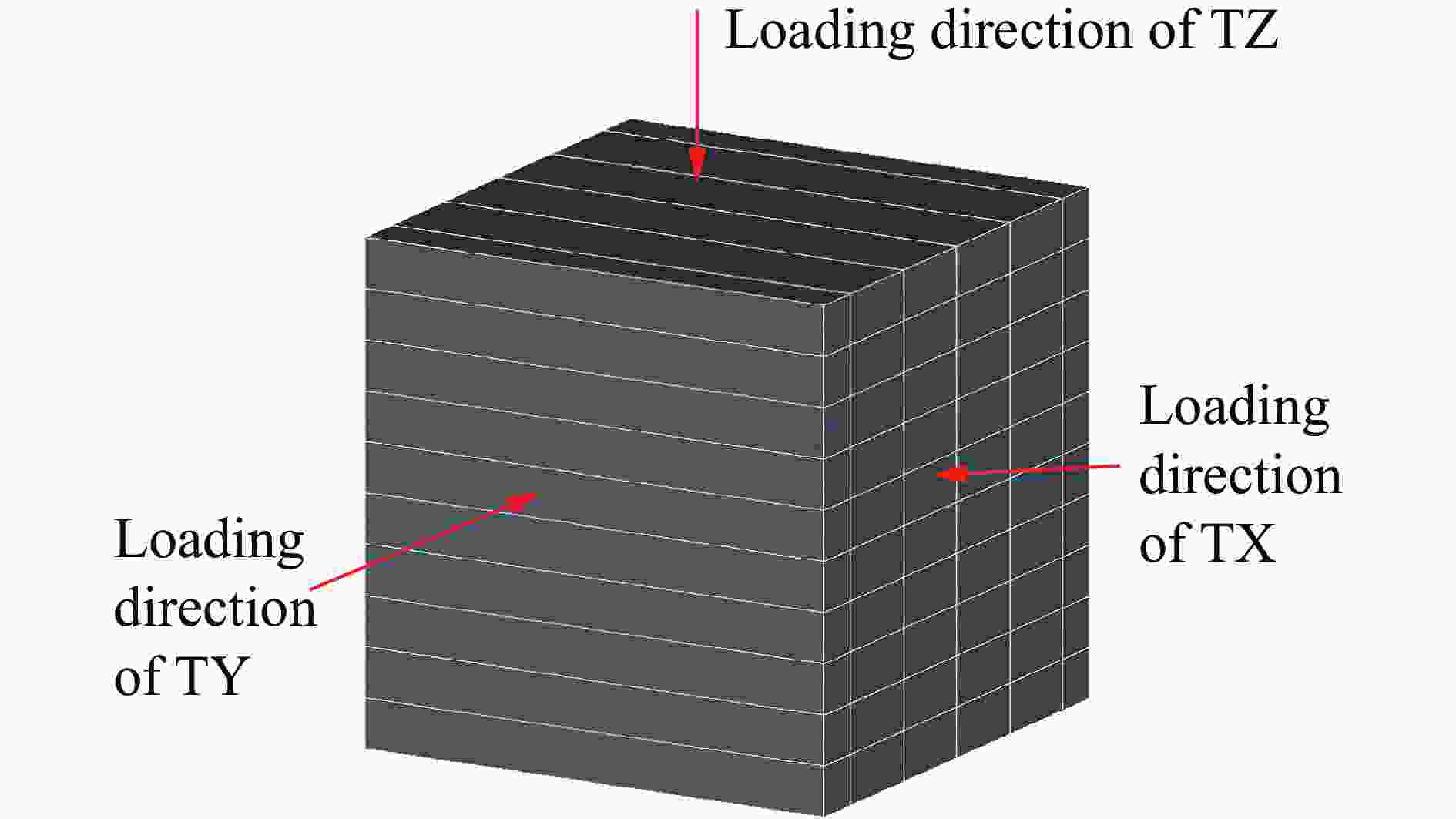

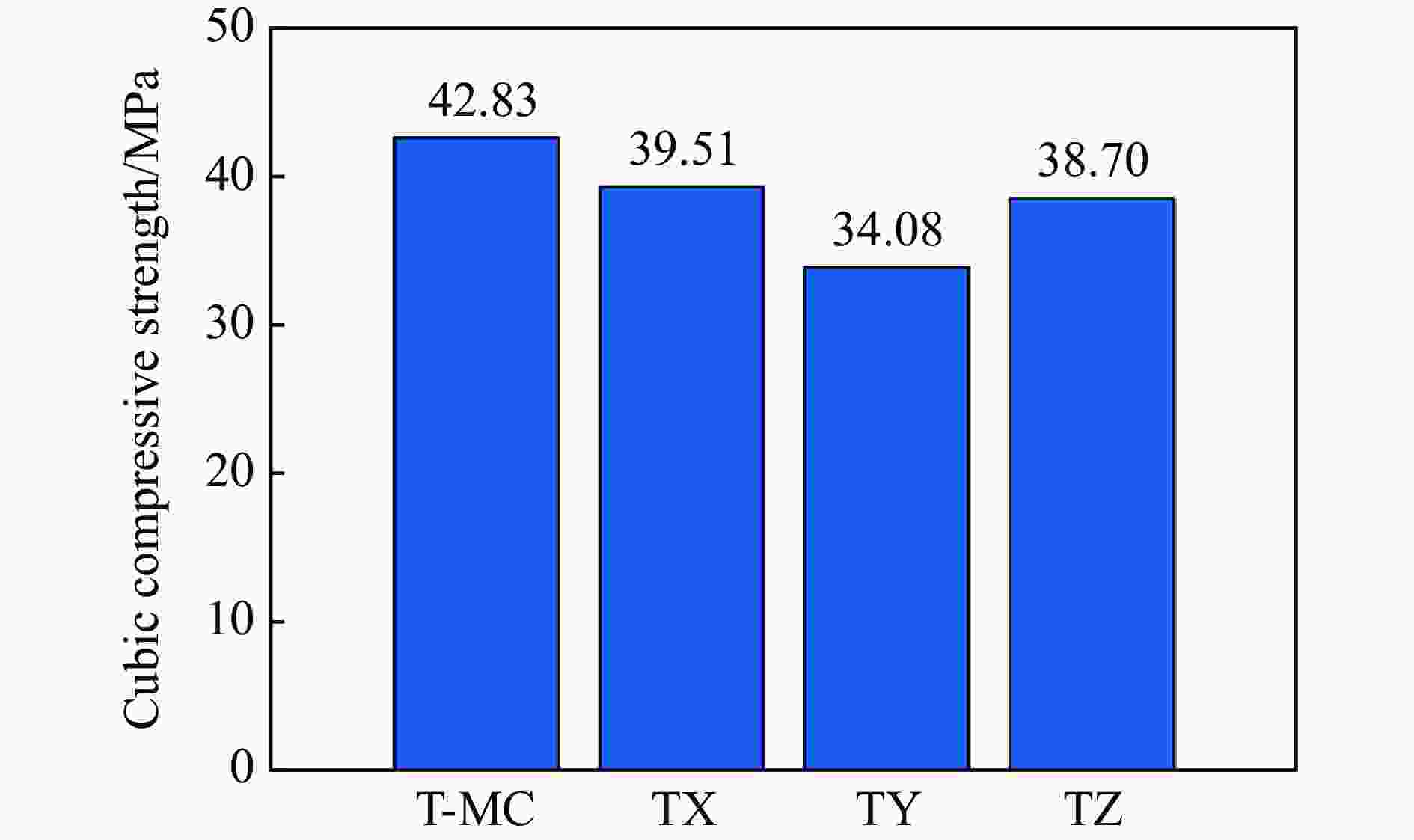

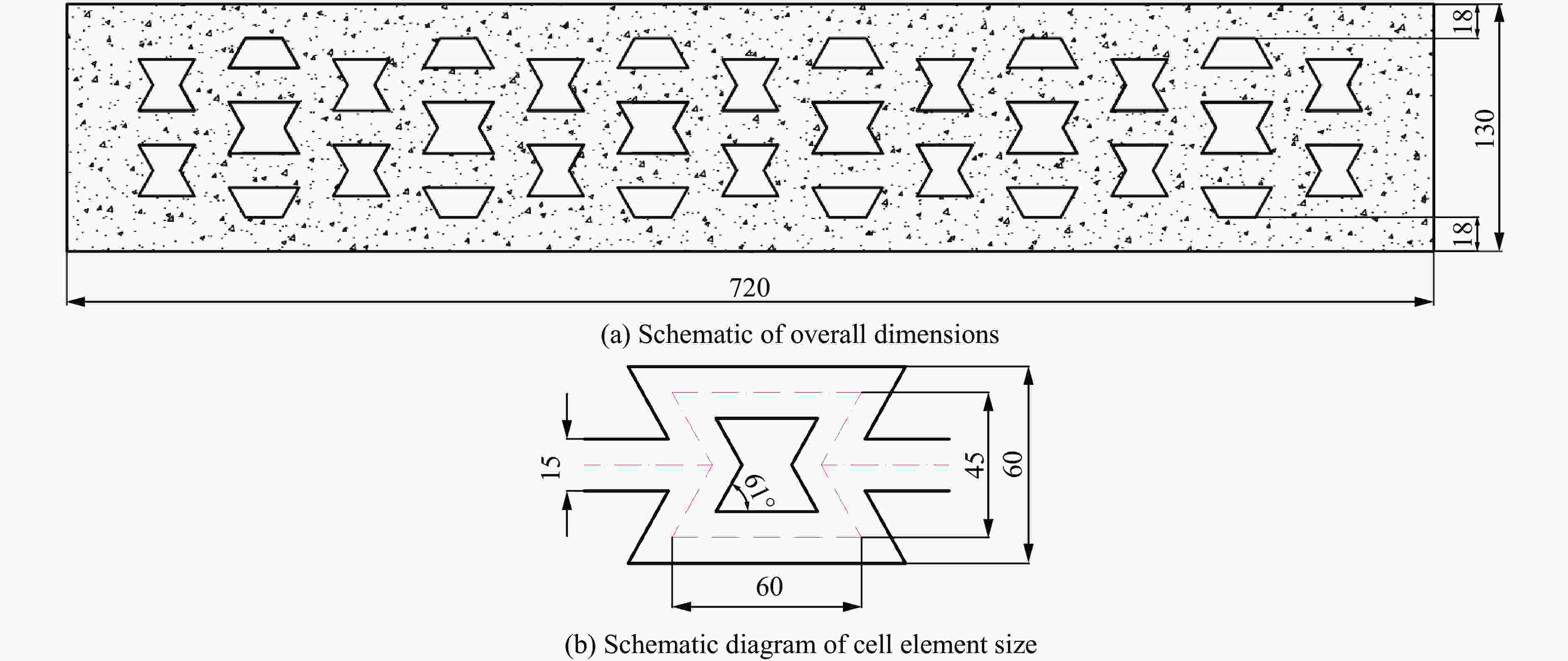

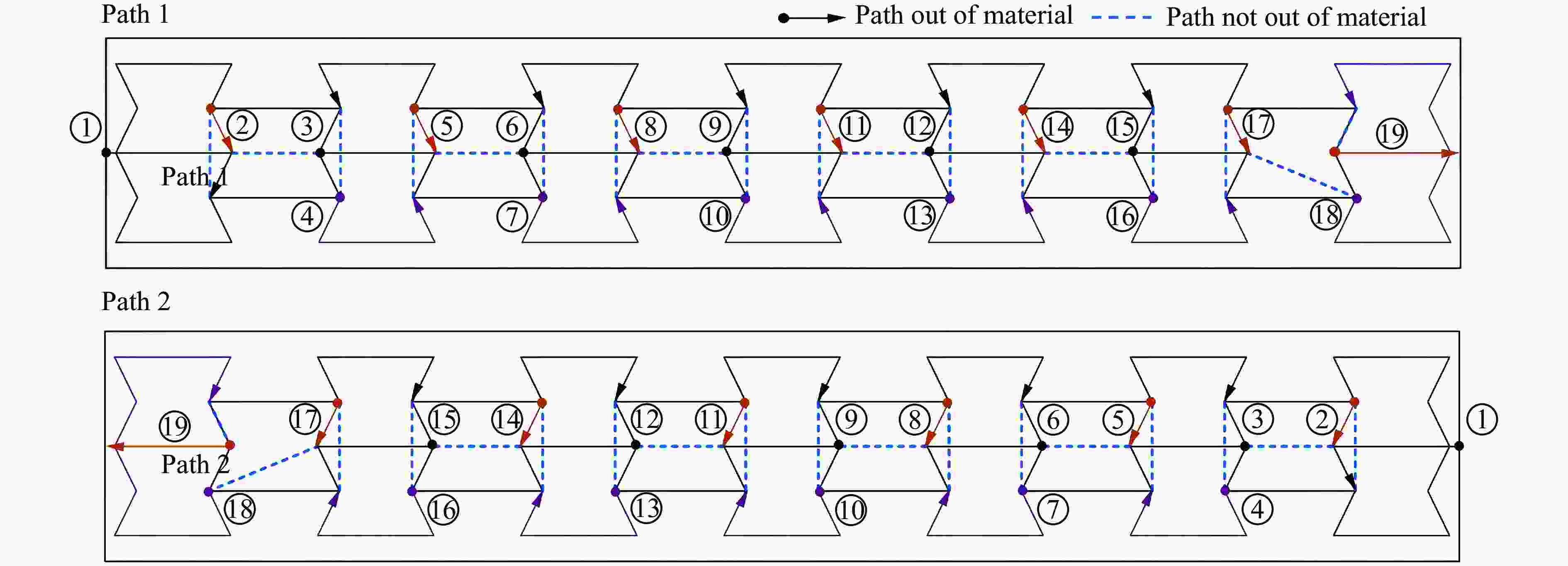

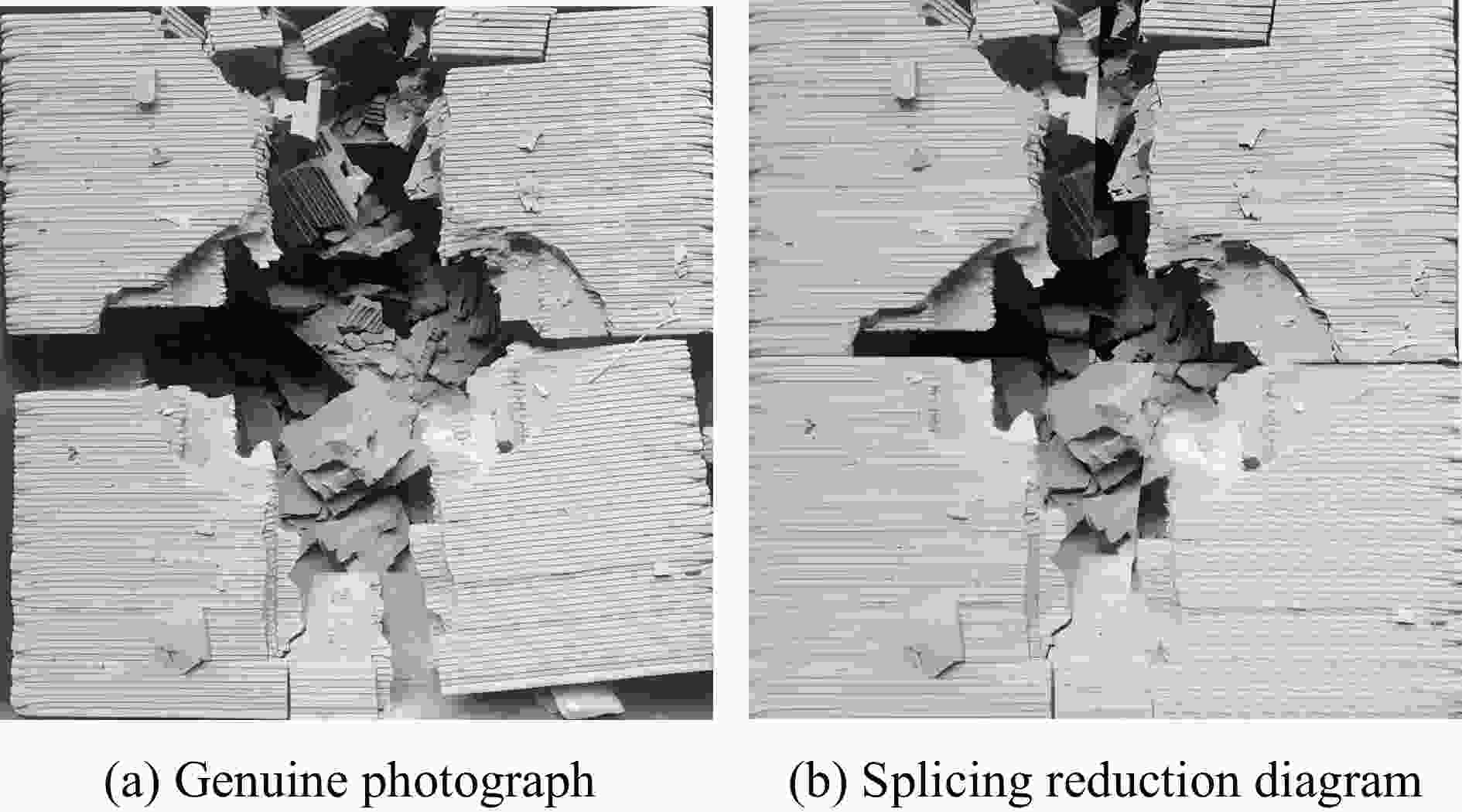

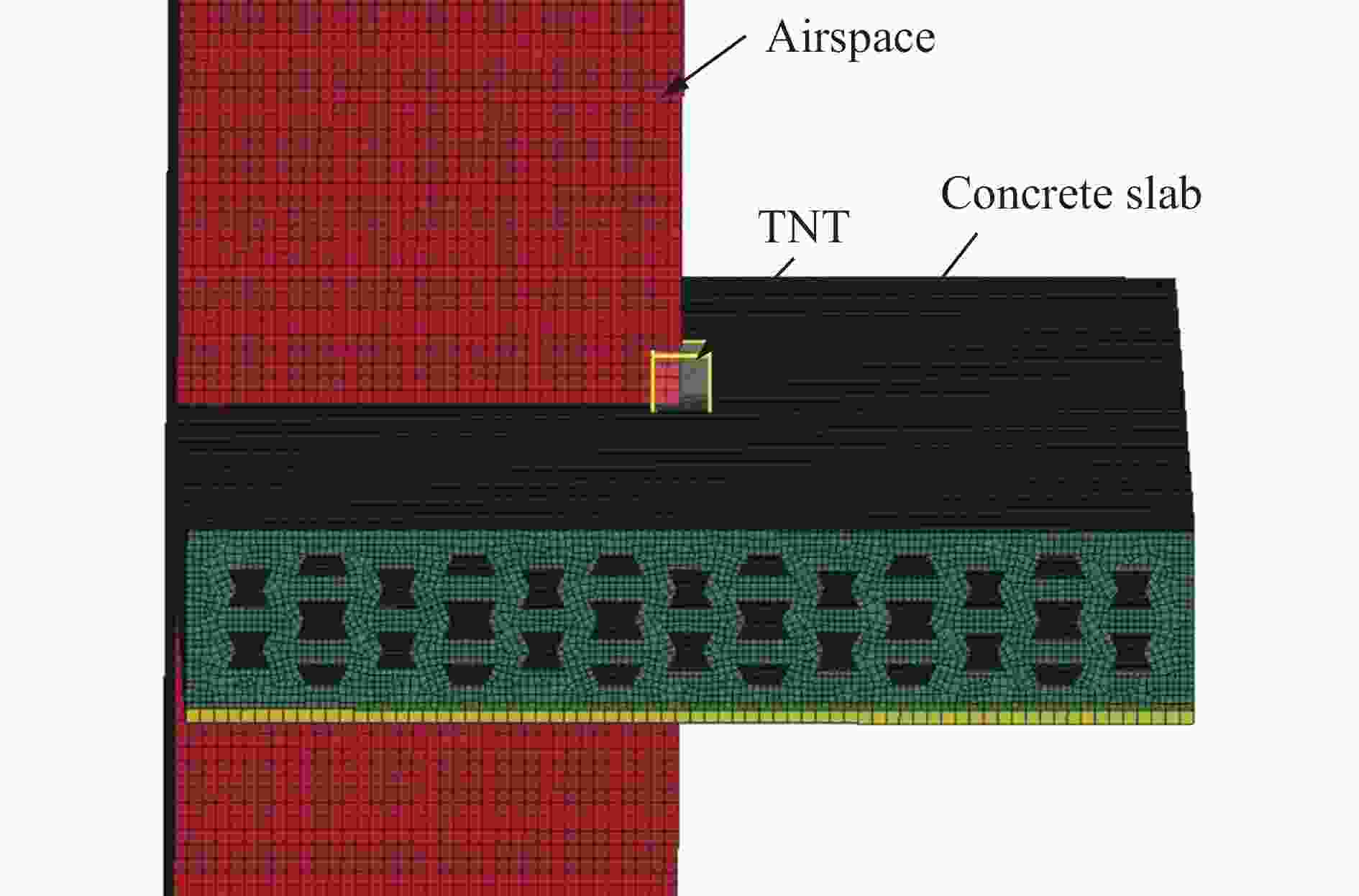

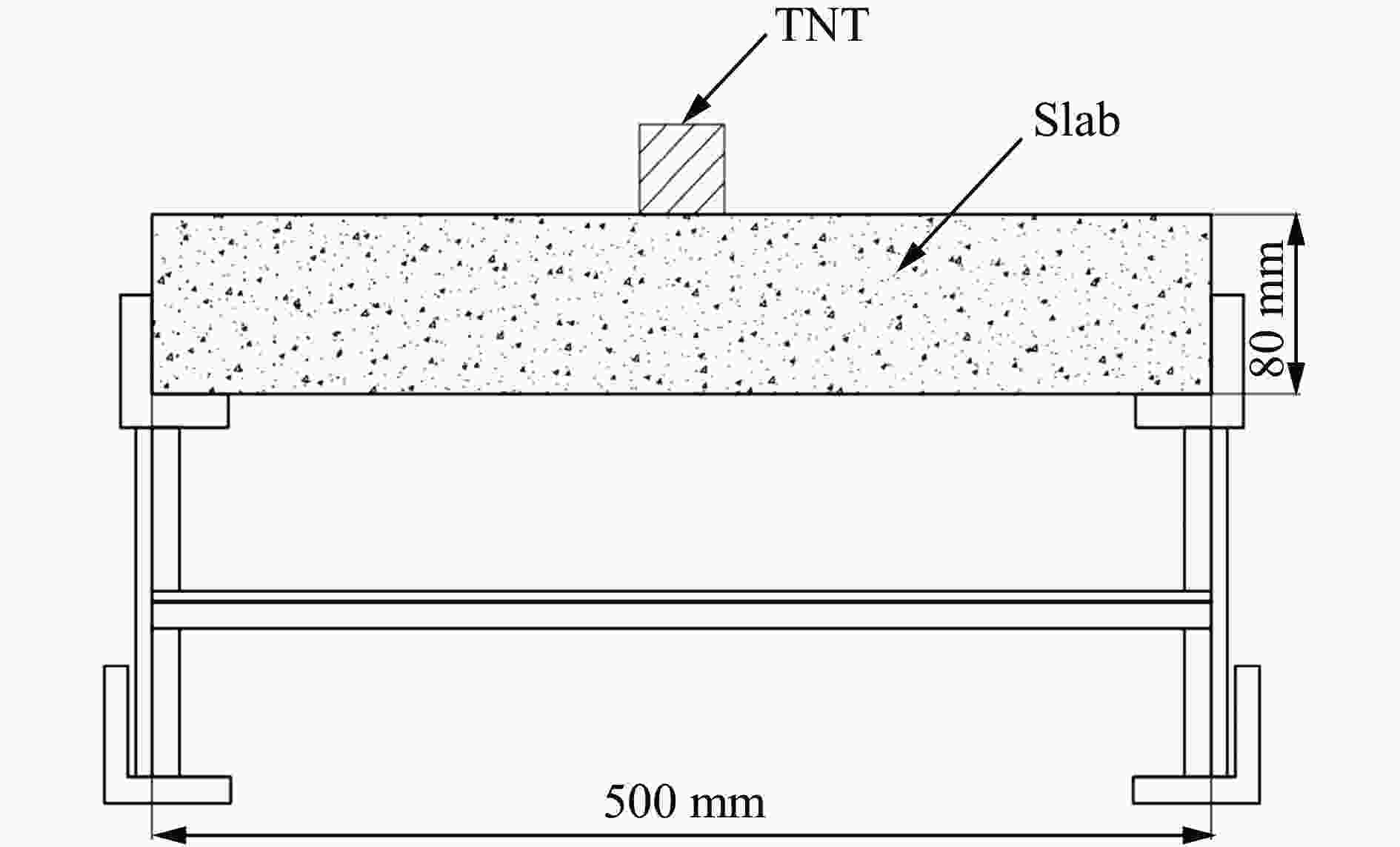

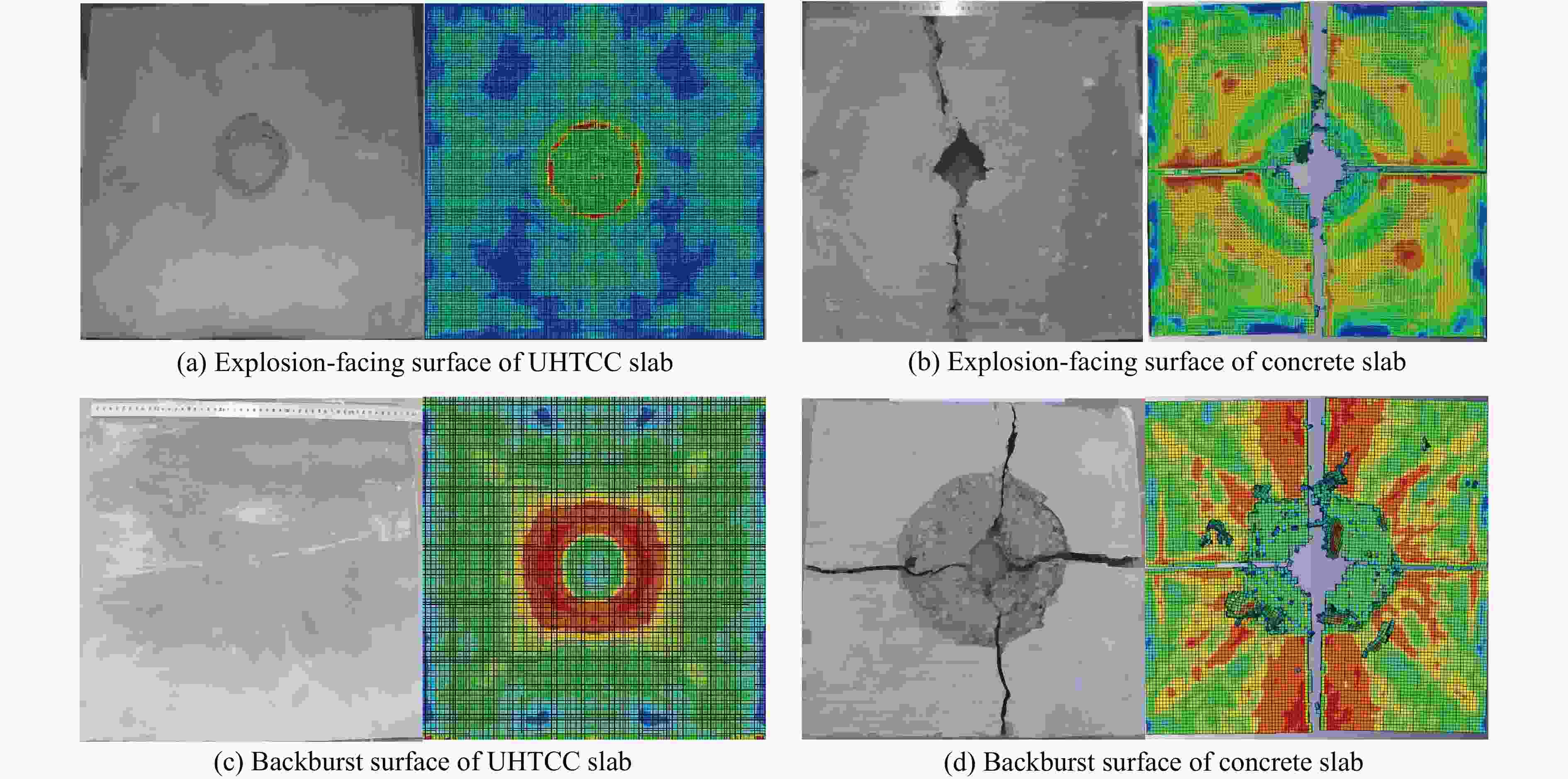

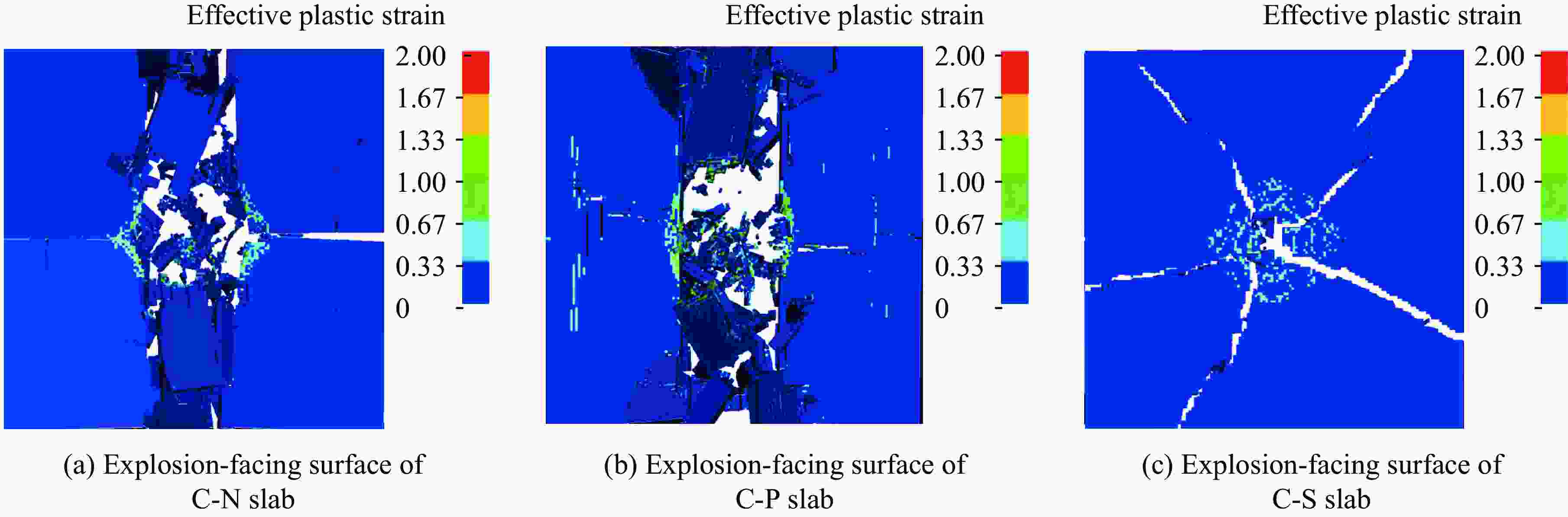

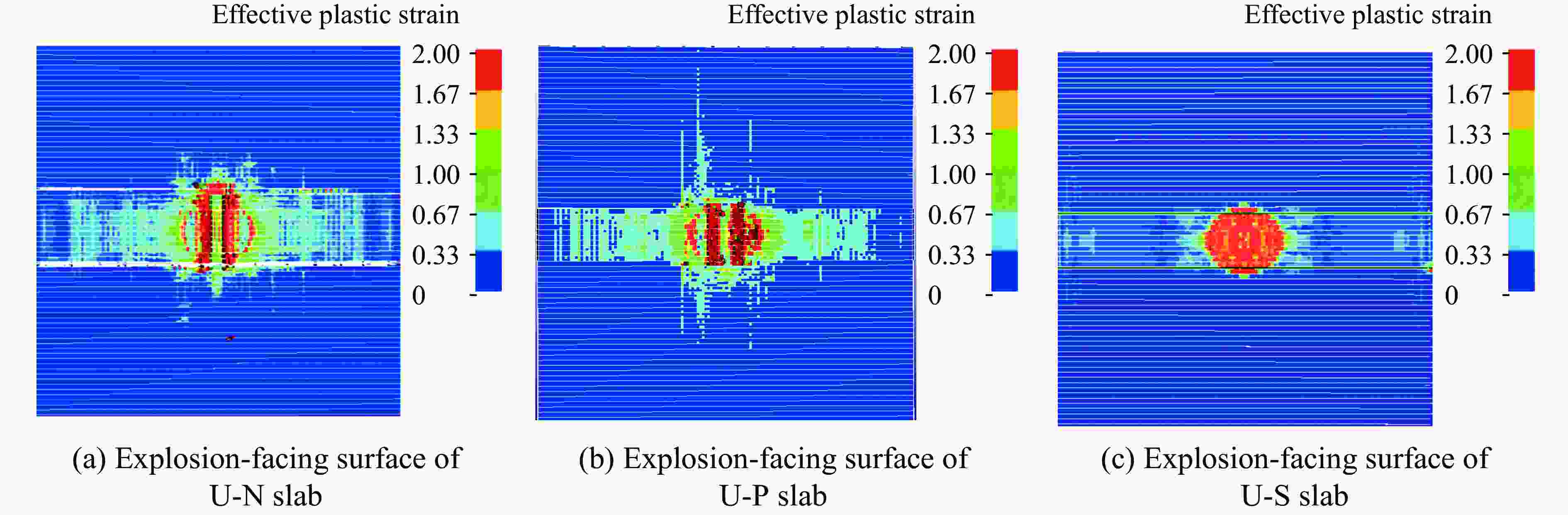

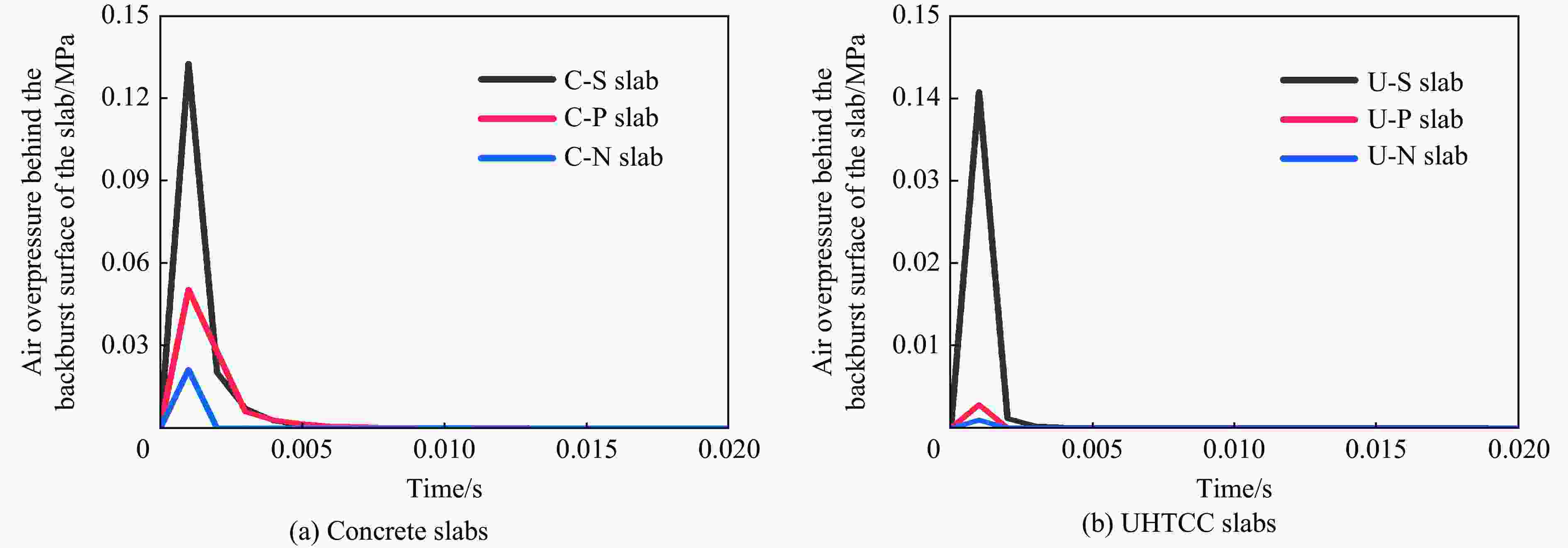

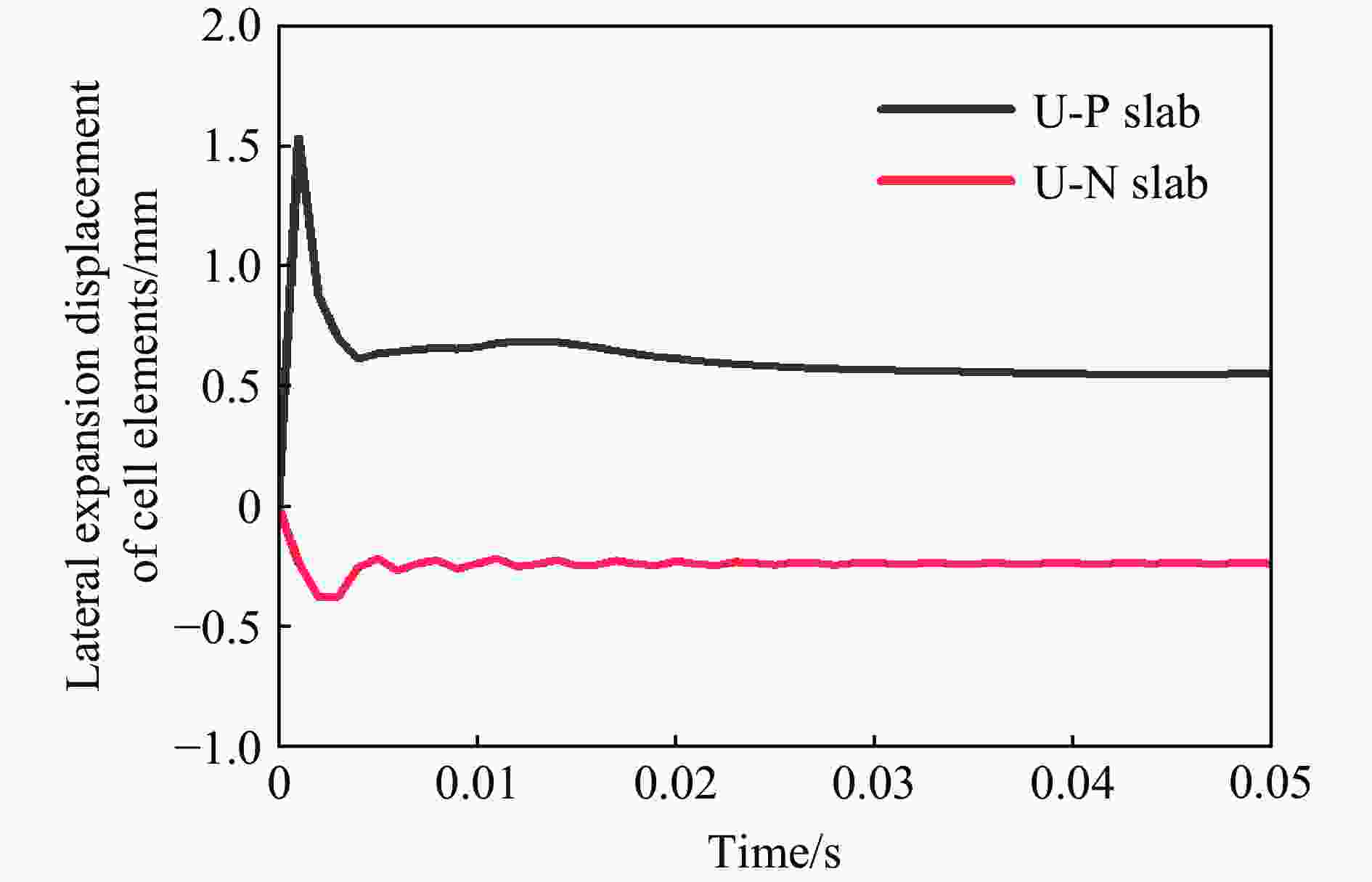

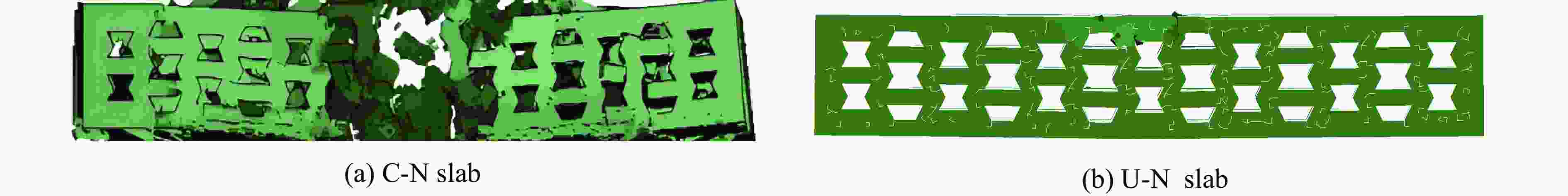

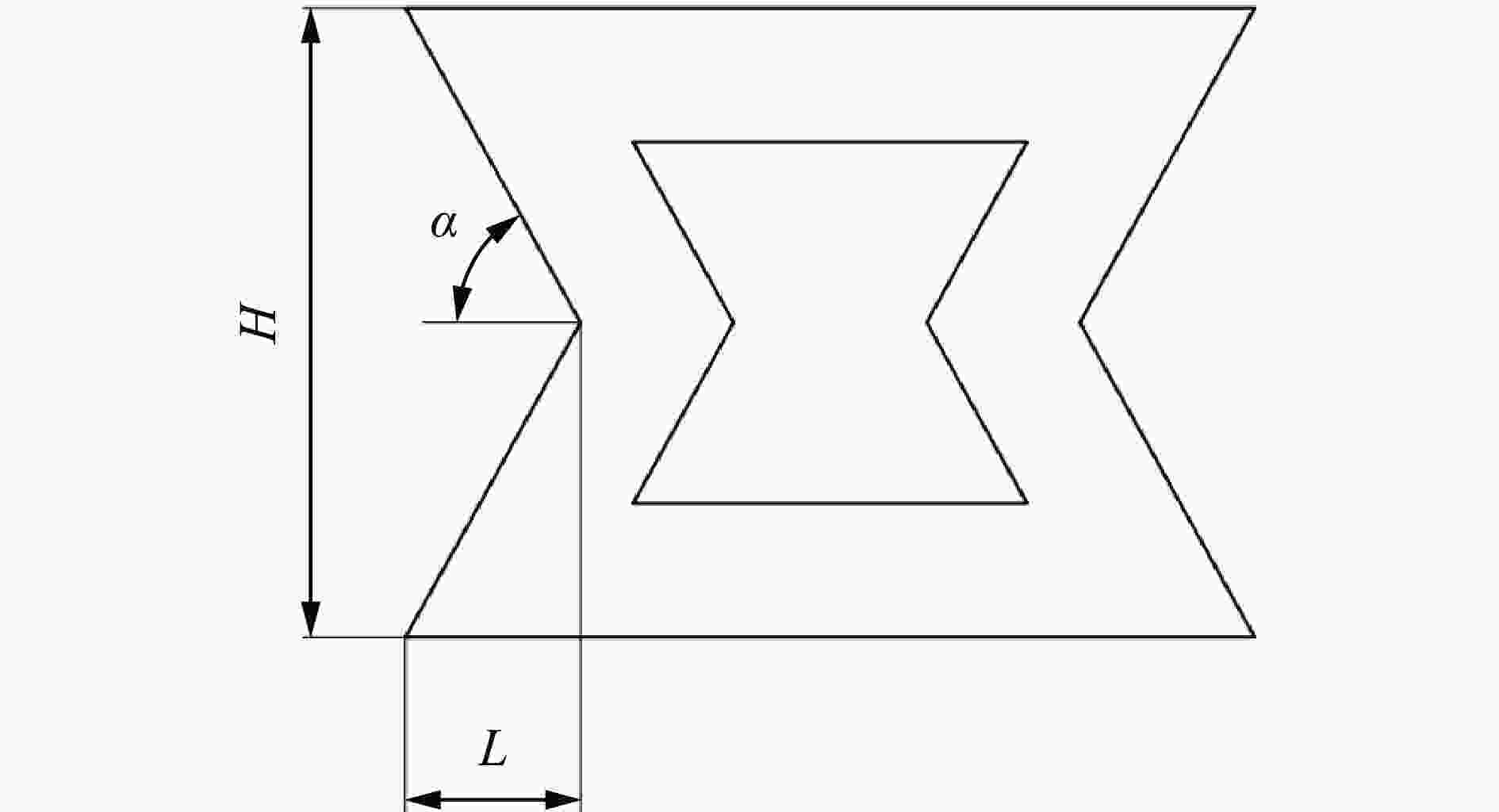

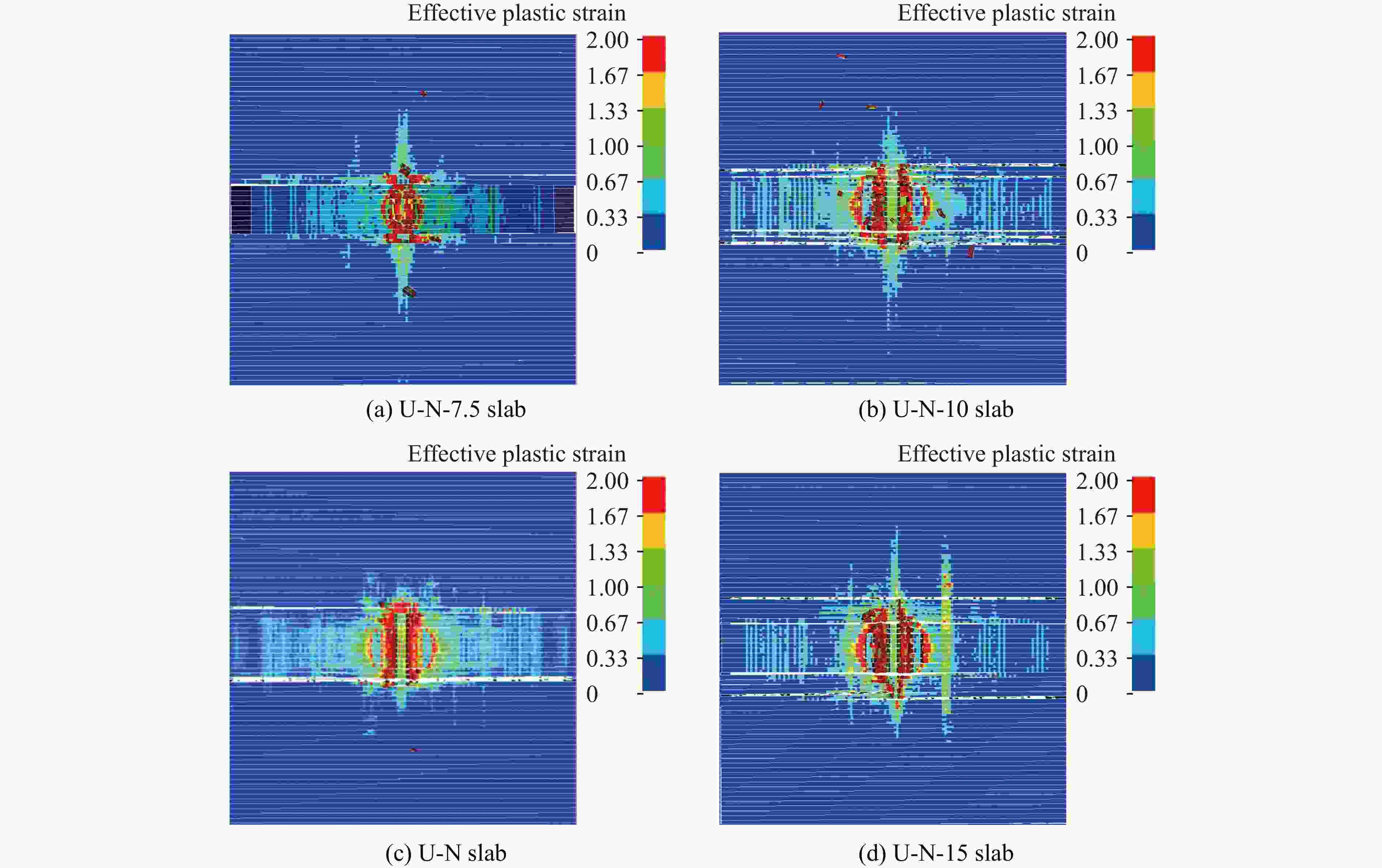

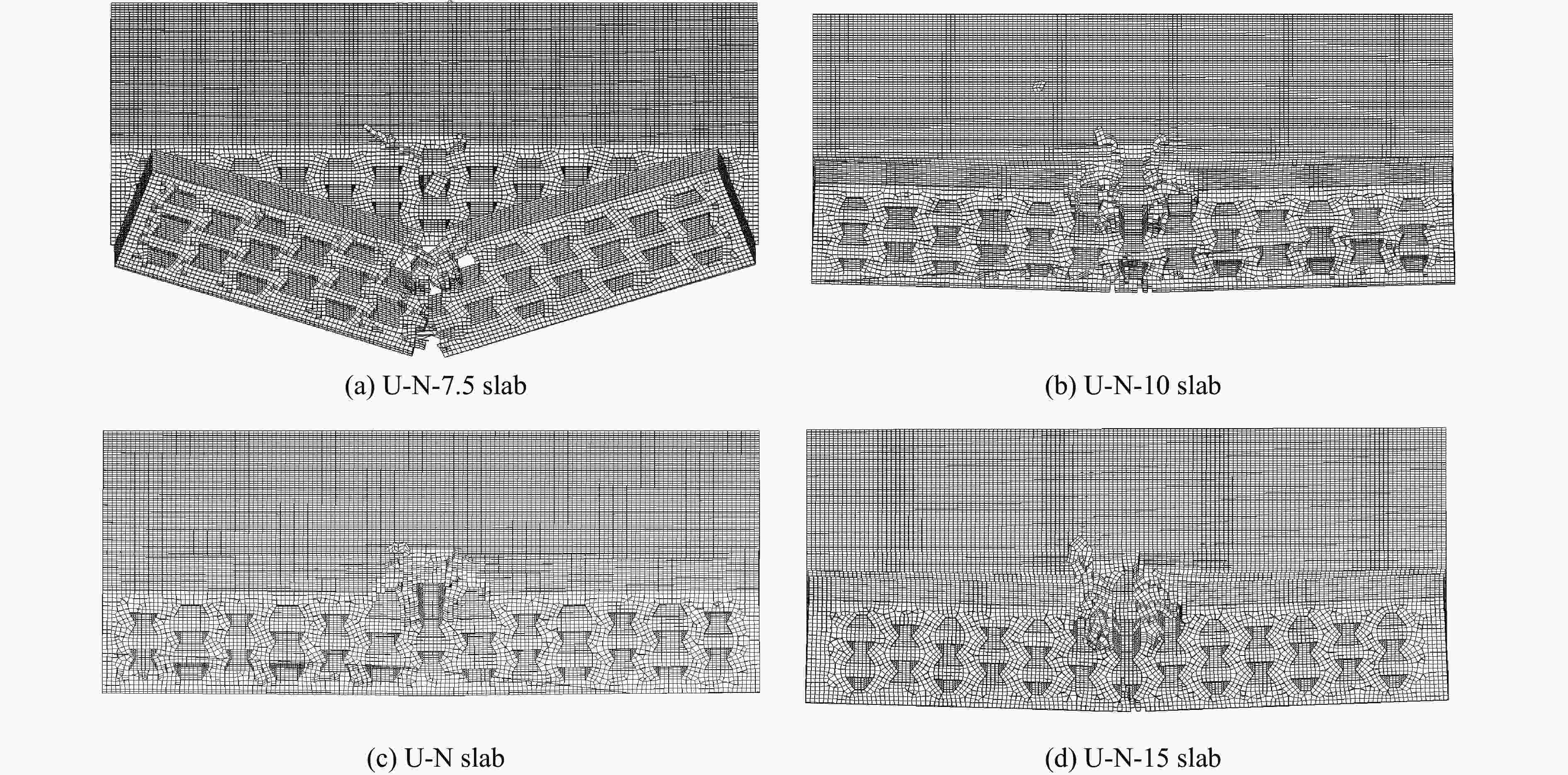

Abstract: In order to improve the explosion resistance of the blast wall, it is proposed to combine the negative Poisson’s ratio structure with ultra-high toughness cementitious composites (UHTCC), and through a combination of the explosion experiment and numerical simulation, the anti-explosive property of the negative Poisson’s ratio slab has been studied, in order to prove the superiority of the anti-explosive properties of the negative Poisson’s ratio UHTCC slab. Firstly, the construction of a negative Poisson’s ratio structural slab was realized by using concrete 3D printing technology and optimizing the printing path, which verified the constructability of the negative Poisson’s ratio structural slab and the negative Poisson’s slab was subjected to a contact explosion test. Using LS-DYNA software, a finite element model of fluid-solid coupling was established in accordance with the explosion test conditions and the finite element model was verified by comparison of the slab damage pattern of the contact explosion test and the slab damage pattern of the simulation. On this basis, the finite element model which has been verified was used to simulate and analyze the effects of different materials of slabs(concrete and UHTCC), different structures of slabs(negative Poisson’s ratio structure, positive Poisson’s ratio structure and solid structure), different cell concave angles and different solid layer thickness ratios on the anti-explosive properties of the negative Poisson’s structural slab under contact explosion. By comparing the slab damage patterns and the ability of energy absorption which was determined by the value of the air overpressure behind the slabs, the design of a negative Poisson’s ratio structure target plate with the best anti-explosive properties was obtained. The results show that: (1) Due to the high toughness, explosion resistance of UHTCC slabs is significantly better than the concrete slabs.The UHTCC slabs all remained intact and the concrete target slabs are all penetrated. (2) Negative Poisson’s ratio slab has the best ability to absorb energy during three kinds of structures, while the solid slab is more able to maintain the structural integrity. (3) When the negative Poisson’s ratio of the cell concave angle is 61°, the structure has optimal explosion resistance, and smaller and larger angle both reduce the explosion resistance of structure. (4) When the thickness of the negative Poisson’s ratio structure is too large as a proportion of the total thickness, the slab is severely damaged. Increasing the solid layer thickness of the backburst surface of the slab or increasing the solid layer thickness of the explosion-facing surface and the backburst surface at the same time is conducive to weakening of the blast shock wave and improving structural integrity. This study confirmed the superiority of the explosion resistance of negative Poisson’s ratio UHTCC slab, and provides a theoretical basis for the design of blast walls based on negative Poisson’s ratio structure. -

表 1 靶板材料参数

Table 1. Material parameters of slabs

材料 抗压强度

fc/MPa抗拉强度

ft/MPa弹性模量

E/GPa泊松比 密度ρ/

(kg·m−3)极限拉

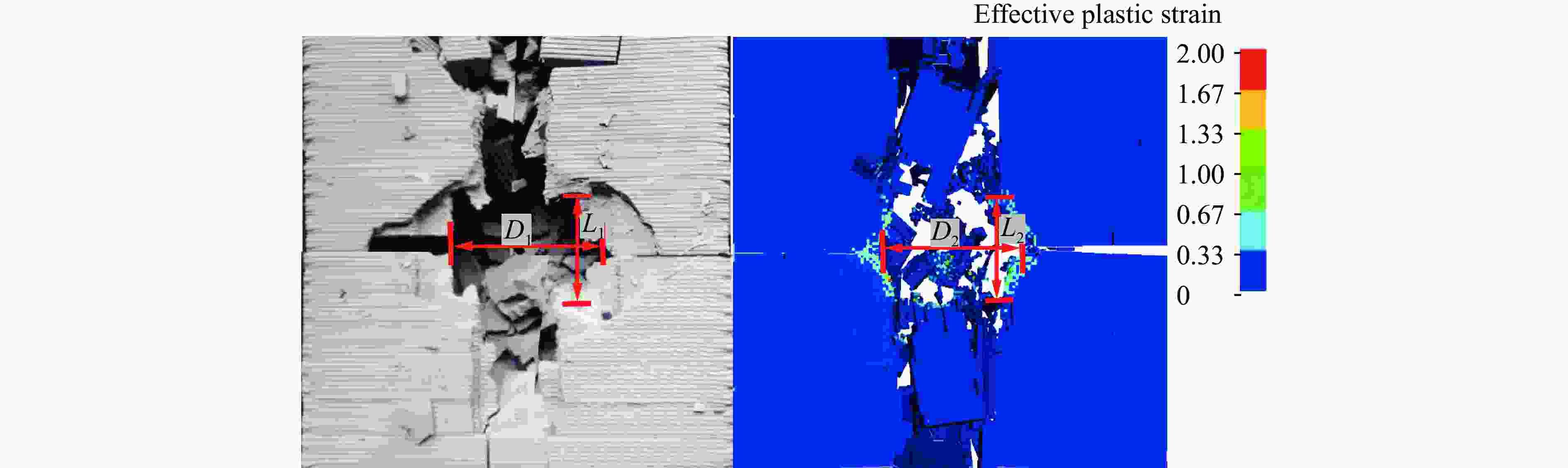

应变$ {\varepsilon }_{\mathrm{u}} $UHTCC 35.7 3.2 17.9 0.2 2040 0.03 混凝土 75 4.2 32 0.2 2300 0.0001 表 2 数值模拟结果与文献[5]中试验所得靶板爆炸开坑尺寸对比

Table 2. Comparison of the dimensions of the exploded crater of the tests in literature[5] and simulation results

靶体材料 开坑直径/mm 漏斗坑深度/mm 试验结果 模拟结果 误差/% 试验结果 模拟结果 误差/% UHTCC 121 128 5.0 24.6 28 13.8 混凝土 170 175 2.9 80 80 \ 表 3 混凝土与UHTCC靶板数值模拟结果

Table 3. Numerical simulation results of concrete and UHTCC slab

靶板材料 背爆面后超压峰值/kPa 负泊松比结构靶板 正泊松比结构靶板 实心结构靶板 混凝土 21.3 50.3 132.5 UHTCC 0.95 2.79 40.20 表 4 不同胞元内凹角靶板模拟结果

Table 4. Simulation results of slabs with different cell element concave angles

靶板名 内伸臂长/

mm内凹/(°) 背爆面后超压

峰值/kPa背爆面跨中

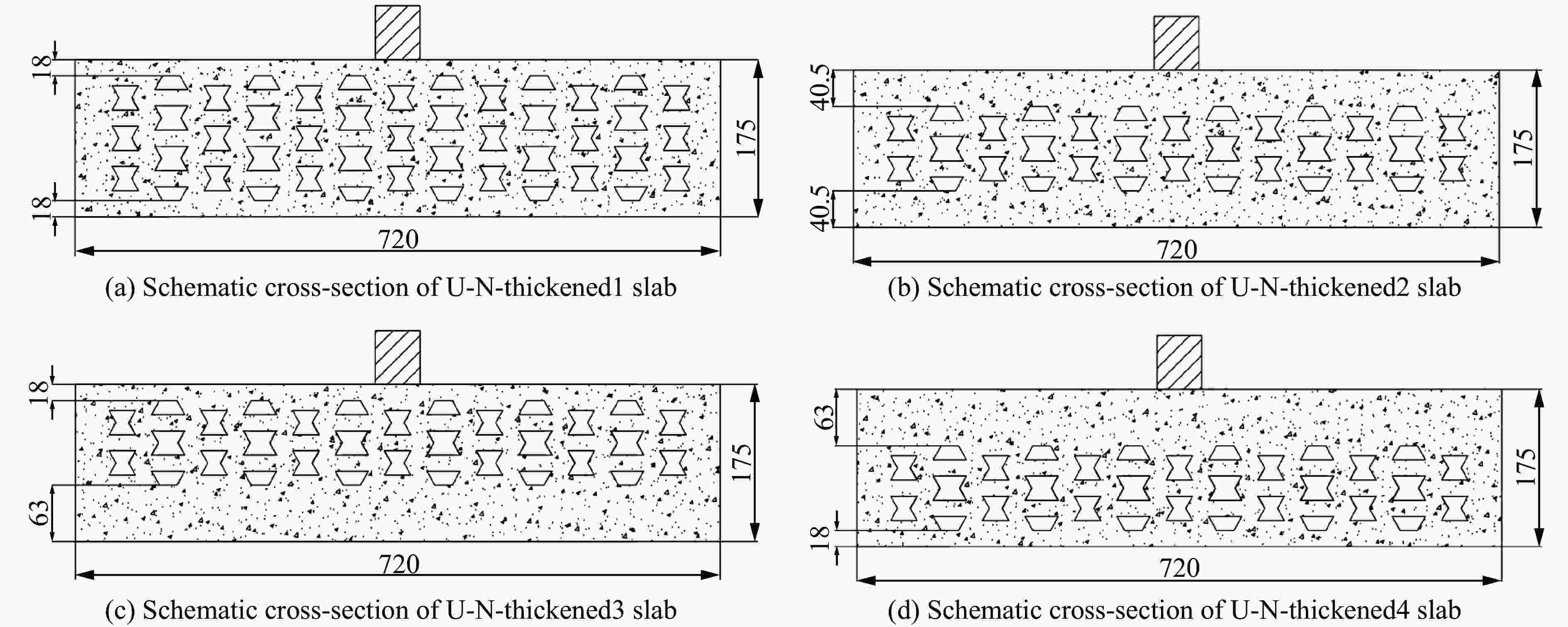

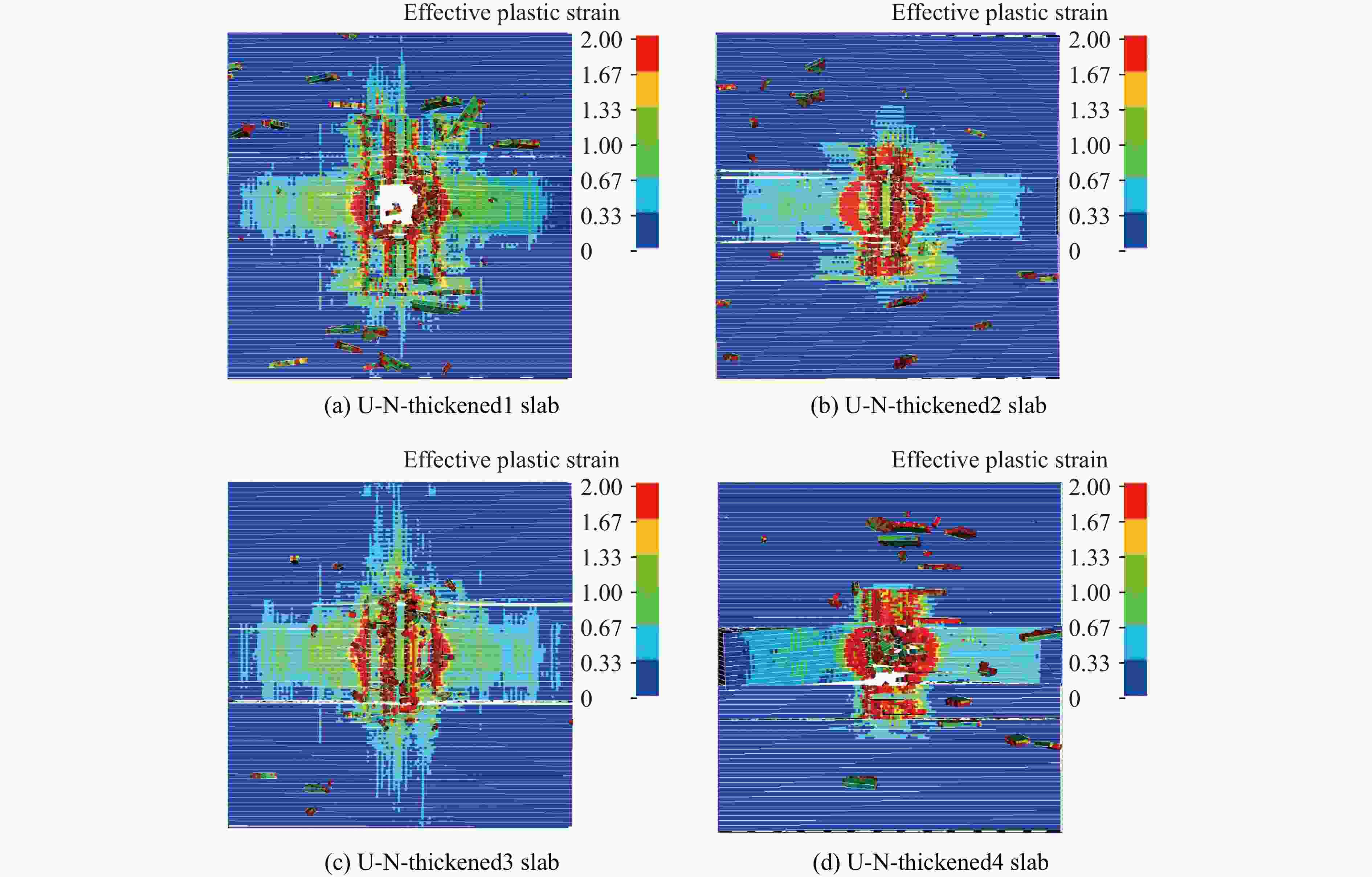

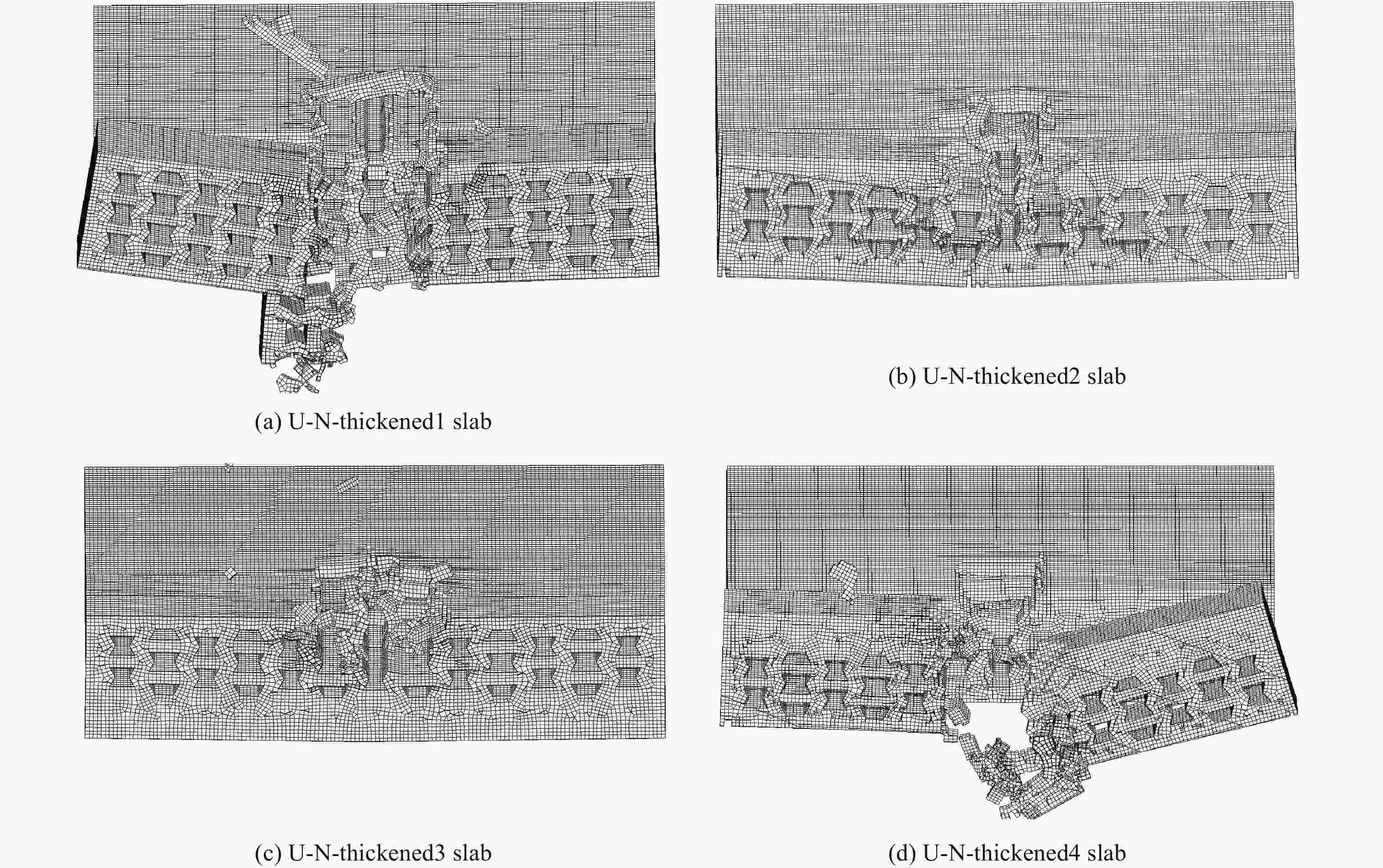

挠度峰值/mmU-N-7.5 7.5 72 36.75 110.0 U-N-10 10.0 66 1.30 12.4 U-N 12.5 61 0.98 3.9 U-N-15 15.0 56 4.04 13.4 表 5 不同截面设计模拟结果

Table 5. Simulation results of different cross-section designs slabs

靶板名 背爆面超压峰值/kPa 破坏形态 背爆面跨中挠度峰值/mm U-N-加厚1 15.43 贯穿 - U-N-加厚2 2.50 相对完整 13.89 U-N-加厚3 3.82 相对完整 5.37 U-N-加厚4 20.28 贯穿 − -

[1] CAMPOS-PIRES R, YONIS A, MACDONALD W, et al. A novel in vitro model of blast traumatic brain injury [J]. Journal of Visualized Experiments, 2018, (142). DOI: 10.3791/58400. [2] 汪维, 张舵, 卢芳云, 等. 配筋率对钢筋混凝土板抗爆性能影响试验研究 [J]. 防护工程, 2015, 37(02): 13–17.WANG W, ZHANG D, LU F Y. Experimental study of reinforcement ratio effect on the anti-blast performance of reinforced concrete plate [J]. Protective Engineering, 2015, 37(02): 13–17. [3] 徐世烺, 李贺东. 超高韧性水泥基复合材料直接拉伸试验研究 [J]. 土木工程学报, 2009, 42(09): 32–41. DOI: 10.15951/j.tmgcxb.2009.09.011.XU S L, LI H D. Uniaxial tensile experiments of ultra-high toughness cementitious composite [J]. China Civil Engineering Journal, 2009, 42(09): 32–41. DOI: 10.15951/j.tmgcxb.2009.09.011. [4] 吴平, 周飞, 李庆华, 等. 超高韧性水泥基复合材料—纤维混凝土组合靶体抗两次打击试验研究 [J]. 爆炸与冲击, 2022, 42(03): 53-65. DOI: 10.11883/bzycj-2021-0178.WU P, ZHOU F, LI Q H, Experimental study on the resistance of the ultra high toughness cementitious composites material-fiber concrete composite targets subjected to twice projectiles impact [J]. Explosion and Shock Waves, 2022, 42(03): 53-65. DOI: 10.11883/bzycj-2021-0178. [5] 徐世烺, 李锐, 李庆华, 陈柏锟. 超高韧性水泥基复合材料功能梯度板接触爆炸数值模拟 [J]. 工程力学, 2020, 37(08): 123–133+178. DOI: 10.6052/j.issn.1000-4750.2019.09.0548.XU S L, LI R, LI Q H. Numberical simulation of functionally graded slabs of ultra-high toughness cementitious composites contact explosion [J]. Engineering Mechanics, 2020, 37(08): 123–133+178. DOI: 10.6052/j.issn.1000-4750.2019.09.0548. [6] 任鹏, 张伟, 刘建华, 黄威. 水下冲击波作用的铝合金蜂窝夹层板动力学响应研究 [J]. 振动与冲击, 2016, 35(02): 7–11+17. DOI: 10.13465/j.cnki.jvs.2016.02.002.REN P, ZHANG W, LIU J H, et al. Dynamic analysis of aluminium alloy honeycomb core sandwich panels subjected to underwater shock loading [J]. Journal of Vibration and Shock, 2016, 35(02): 7–11+17. DOI: 10.13465/j.cnki.jvs.2016.02.002. [7] 何秋霖, 石少卿, 崔廉明, 等. 轻质材料构筑的蜂窝防护结构抗爆性能试验与数值模拟研究 [J]. 材料导报, 2020, 34(24): 24023–24028. DOI: 10.11896/cldb.19120249.HE Q L, SHI S Q, CUI L M, et al. Research on blast-resistant performance and numerical simulation of honeycomb protective structure constructed of lightweight materials [J]. Materials Reports, 2020, 34(24): 24023–24028. DOI: 10.11896/cldb.19120249. [8] 卢子兴, 李康. 负泊松比蜂窝动态压溃行为的有限元模拟 [J]. 机械强度, 2016, 38(06): 1237–1242. DOI: 10.16579/j.issn.1001.9669.2016.06.018.LU Z X, LI K. Dynamic crushing of honeycombs with a negative Poisson’s ratio—a finite element study [J]. Journal of Mechanical Strength, 2016, 38(06): 1237–1242. DOI: 10.16579/j.issn.1001.9669.2016.06.018. [9] 杨德庆, 马涛, 张梗林. 舰艇新型宏观负泊松比效应蜂窝舷侧防护结构 [J]. 爆炸与冲击, 2015, 35(02): 243–248. DOI: 10.11883/1001-1455(2015)02-0243-06.YANG D Q, MA T, ZHANG G L. A novel auxetic broadside defensive structure for naval ships [J]. Explosion and Shock Waves, 2015, 35(02): 243–248. DOI: 10.11883/1001-1455(2015)02-0243-06. [10] 夏玮, 刘见华, 叶帆. 宏观负泊松比板架结构远场水下抗爆性能研究 [J]. 船舶, 2021, 32(06): 33–40. DOI: 10.19423/j.cnki.31-1561/u.2021.06.033.XIA W, LIU J H, Y F. On far-field underwater anti-explosion performance of macroscopic negative Poisson’s ratio grillage structure [J]. Ship & Boat, 2021, 32(06): 33–40. DOI: 10.19423/j.cnki.31-1561/u.2021.06.033. [11] 马芳武, 王强, 马文婷, 等. 混合梯度负泊松比结构多工况耐撞性研究 [J]. 华南理工大学学报(自然科学版), 2022, 50(07): 85–97. DOI: 10.12141/j.issn.1000-565X.210696.MA F W, WANG Q, MA W T, et al. Study on crashworthiness of hybrid gradient negative poisson’s ratio structure under multi-conditions [J]. Journal of South China University of Technology (Natural Science Edition), 2022, 50(07): 85–97. DOI: 10.12141/j.issn.1000-565X.210696. [12] 吴东伟, 郁荣, 钱卫东, 刘敬喜. 增强型负泊松比舷侧防护结构吸能特性研究 [J]. 船舶物资与市场, 2024, 32(11): 24–27. DOI: 10.19727/j.cnki.cbwzysc.2024.11.008.WU D W, Y R, QIAN W D, et al. Study on the energy absorption characteristics of enhanced negative Poisson’s ratio outboard protection structure [J]. Marine Equipment/Materials & Marketing, 2024, 32(11): 24–27. DOI: 10.19727/j.cnki.cbwzysc.2024.11.008. [13] 宋晓辉, 李梦瑶, 周晓杰, 等. 钢筋混凝土的负泊松比设计及其常规力学性能研究 [J]. 青岛理工大学学报, 2020, 41(05): 1–8. DOI: 10.3969/j.issn.1673-4602.2020.05.002.SONG X H, LI M Y, ZHOU X J, et al. Negative Poisson’s ratio design of reinforced concrete and research of its conventional mechanical properties [J]. Journal of Qingdao University of Technology, 2020, 41(05): 1–8. DOI: 10.3969/j.issn.1673-4602.2020.05.002. [14] 赵飞, 朱鹏飞, 李梦瑶, 等. 钢筋混凝土的负泊松比设计与抗弯性能研究 [J]. 硅酸盐通报, 2023, 42(05): 1640–1649. DOI: 10.16552/j.cnki.issn1001-1625.2023.05.005.ZHAO F, ZHU P F, LI M Y, et al. Negative Poisson ratio design and flexural performance of reinforced concrete [J]. Bulletin of the Chinese Ceramic Society, 2023, 42(05): 1640–1649. DOI: 10.16552/j.cnki.issn1001-1625.2023.05.005. [15] ZHIQIANG Y, ZHENGUO S, CHAO Q, et al. Static compressive properties of polypropylene fiber foam concrete with concave hexagonal unit cell [J]. Applied Sciences, 2022, 13(1): 132. DOI: 10.3390/APP13010132. [16] 邱琢皓, 董嘉靖, 彭光健, 等. 聚氨酯泡沫增强3D打印PLA蜂窝结构的压缩性能研究 [J]. 复合材料学报, 2024: 1–13. DOI: 10.13801/j.cnki.fhclxb.20241220.001.QIU Z H, DONG J J, PENG G J, et al. Study on the compressive properties of polyurethane foam reinforced 3D printed PLA honeycomb structure [J]. Acta Materiae Compositae Sinica, 2024: 1–13. DOI: 10.13801/j.cnki.fhclxb.20241220.001. [17] 中华人民共和国住房和城乡建设部. JGJ/T 70-2009建筑砂浆基本性能试验方法标准 [S]. 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People`s Republic of China. Standard for test method of basic properties of construction mortar: JGJ/T 70-2009 [S]. China Architecture & Building Press, 2009. [18] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB-50010-2010 [S]. 中国建筑工业出版社, 2014.Ministry of Housing and Urban-Rural Development of the People`s Republic of China. Code for design of concrete structure: GB-50010-2010 [S]. China Architecture & Building Press, 2014. [19] LE T T, AUSTIN S A, LIM S, et al. Hardened properties of high-performance printing concrete [J]. Cement & Concrete Research, 2012, 42(3): 558–566. DOI: 10.1016/j.cemconres.2011.12.003. [20] CEB-FIB. fib model code for concrete structures 2010 [S]. Berlin: Wilhelm Ernst&Sohn, 2013. [21] 马宗方, 万伟鹏, 宋琳, 等. 采用欧拉回路的混凝土3D打印路径优化算法 [J]. 机械科学与技术, 2024, 43(11): 1954–1960. DOI: 10.13433/j.cnki.1003-8728.20230082.MA Z F, WAN W P, SONG L, et al. Path optimization algorithm for 3D printing of concreteusing euler circuit [J]. Mechanical Science and Technology for Aerospace Engineering, 2024, 43(11): 1954–1960. DOI: 10.13433/j.cnki.1003-8728.20230082. [22] 杨敏, 来猛刚, 窦艳宁, 田果. 混凝土3D打印质量影响因素及控制方法 [J]. 混凝土与水泥制品, 2021(04): 11–16. DOI: 10.19761/j.1000-4637.2021.04.011.06.YANG M, LAI M G, DOU Y N, et al. Influencing factors and control measures of concrete 3d printing quality [J]. China Concrete and Cement Products, 2021(04): 11–16. DOI: 10.19761/j.1000-4637.2021.04.011.06. [23] 杜闯, 宋帅, 张江鹏. 爆炸冲击作用下三种混凝土本构模型对比研究 [J]. 兵器装备工程学报, 2022, 43(11): 49–56. DOI: 10.11209/bqzbgcxb2022.00.007.DU C, SONG S, ZHANG J P. Comparative study on three concrete constitutive models under blast loading [J]. Journal of Ordnance Equipment Engineering, 2022, 43(11): 49–56. DOI: 10.11209/bqzbgcxb2022.00.007. [24] 吴赛, 赵均海, 张冬芳, 王娟. 自由空气中爆炸冲击波的数值分析 [J]. 工程爆破, 2019, 25(3): 1–6,31. DOI: 10.3969/j.issn.1006-7051.2019.03.001.WU S, ZHAO J H, ZHANG D F, et al. Numerical analysis of explosion wave in free air [J]. Engineering Blasting, 2019, 25(3): 1–6,31. DOI: 10.3969/j.issn.1006-7051.2019.03.001. [25] JOHNSON H G R. A computational constitutive model for glass subjected to large strains, high strain rates and high pressures [J]. Journal of Applied Mechanics, 2011, 78(5): 051003. DOI: 10.1115/1.4004326. [26] 徐世烺, 吴平, 李庆华, 等. 超高韧性水泥基复合材料K&C模型参数确定 [J]. 建筑结构学报, 2022, 43(06): 233–244+256. DOI: 10.14006/j.jzjgxb.2020.0587.XU S L, WU P, LI Q H. Determination of K&C model parameters for ultra-high toughness cementitious composites [J]. Journal of Building Structures, 2022, 43(06): 233–244+256. DOI: 10.14006/j.jzjgxb.2020.0587. [27] THOMSEN W M. High strain rate analysis of 3d printed concrete as compared to conventionally cast concrete [D], Rolla, MO, USA: Missouri University of Science and Technology, 2024. [28] B J X A, A H L, B T D A. Finite element analysis on the anisotropic behavior of 3D printed concrete under compression and flexure [J]. Additive Manufacturing, 2020. DOI: 10.1016/j.addma.2020.101712. [29] 张新春, 刘颖, 李娜. 具有负泊松比效应蜂窝材料的面内冲击动力学性能 [J]. 爆炸与冲击, 2012, 32(5): 475–482. DOI: 10.3969/j.issn.1001-1455.2012.05.005.ZHANG X C, LIU Y, LI N. In-plane dynamic crushing of honeycombs with negative Poisson’s ratio effects [J]. Explosion and Shock Waves, 2012, 32(5): 475–482. DOI: 10.3969/j.issn.1001-1455.2012.05.005. -

下载:

下载: