Formation mechanism and damage characteristics of a high-entropy alloy/al/ptfe double-layer composite liner with a truncated inner layer

-

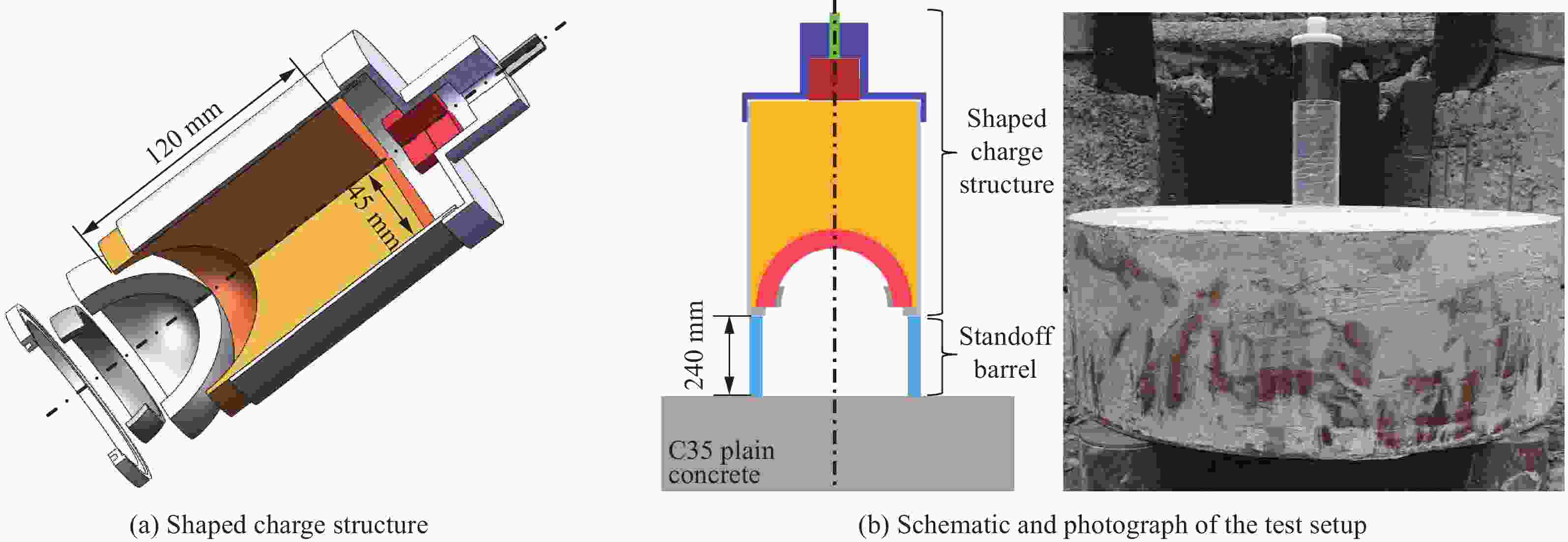

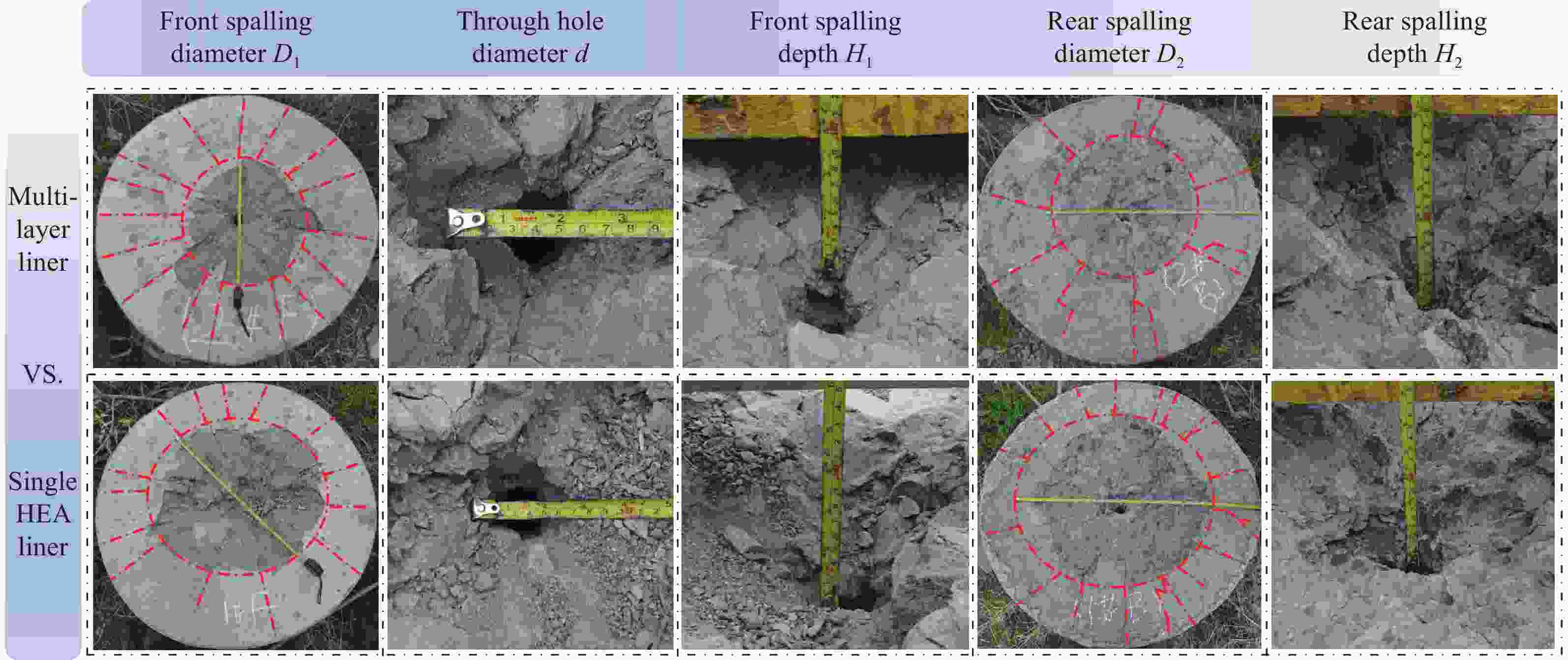

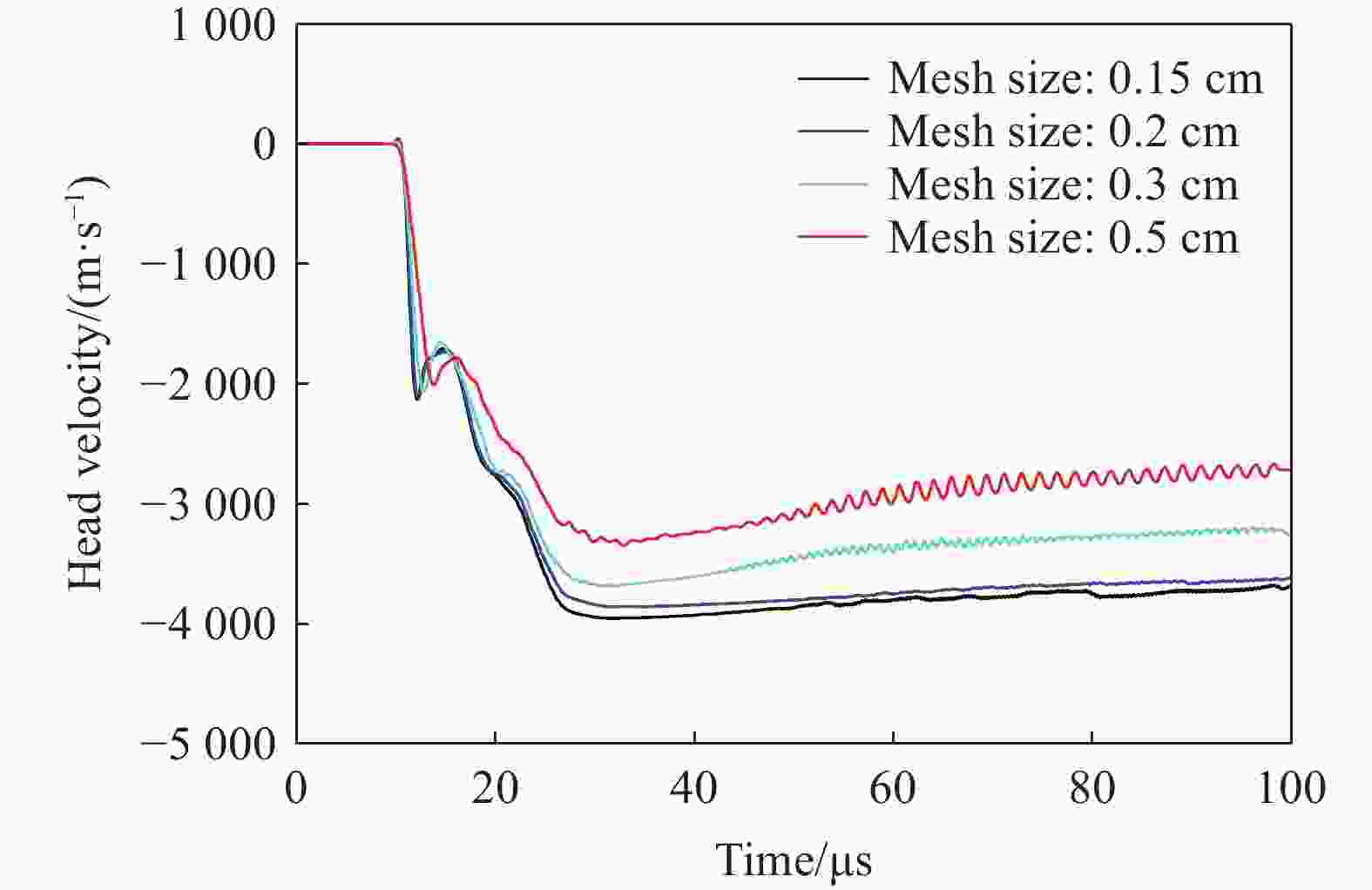

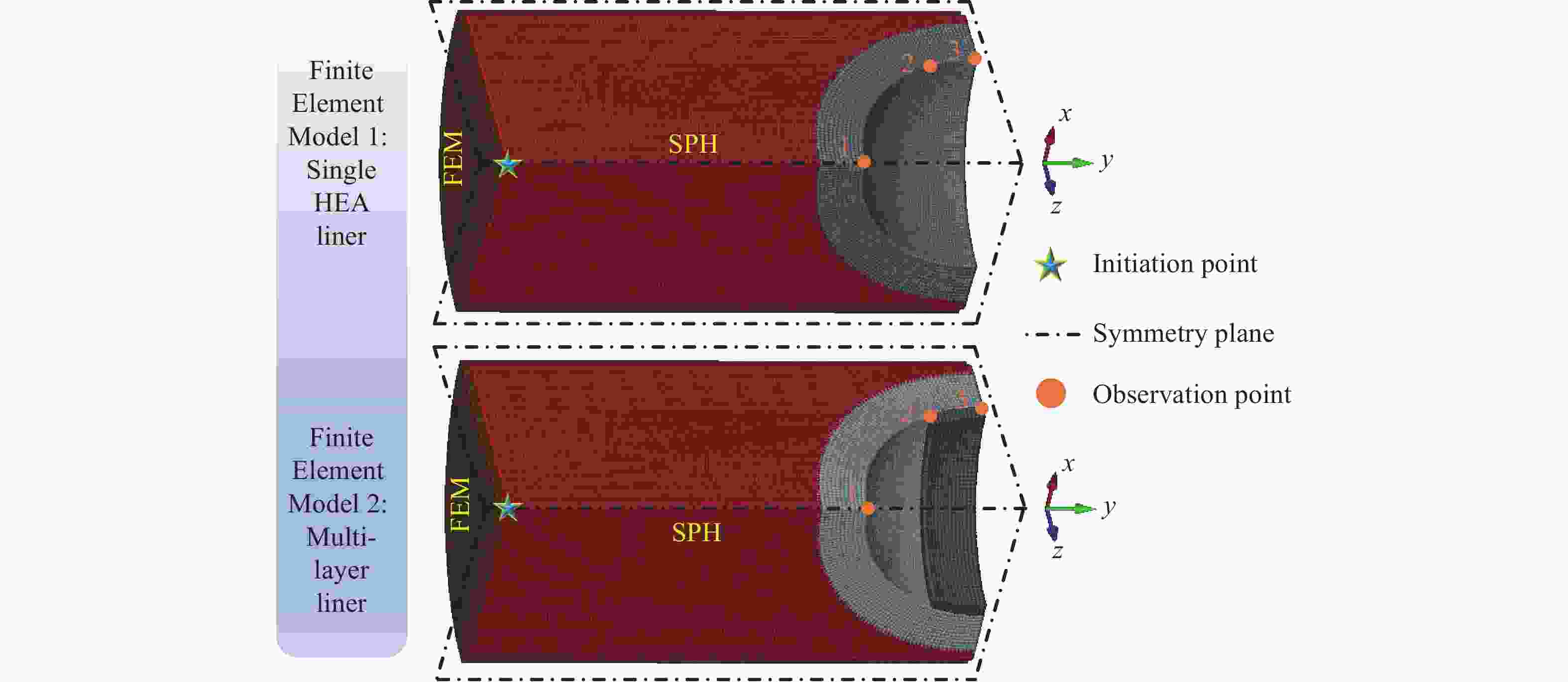

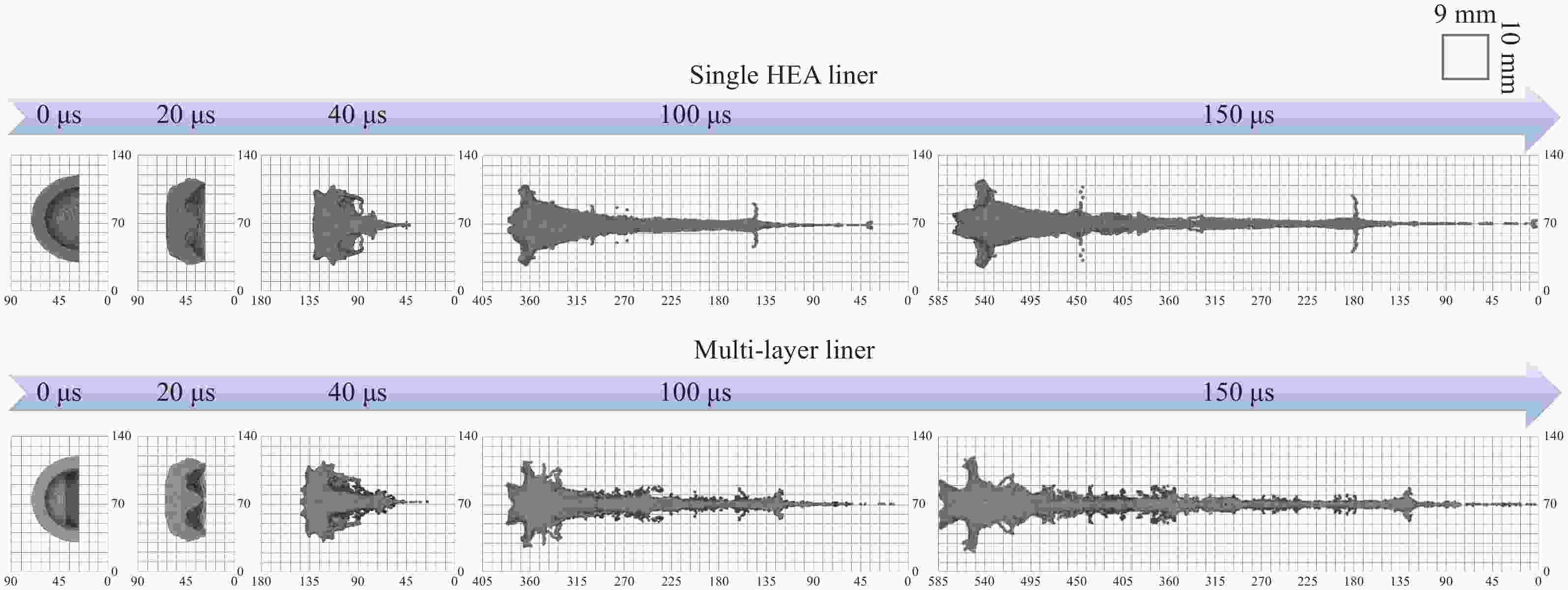

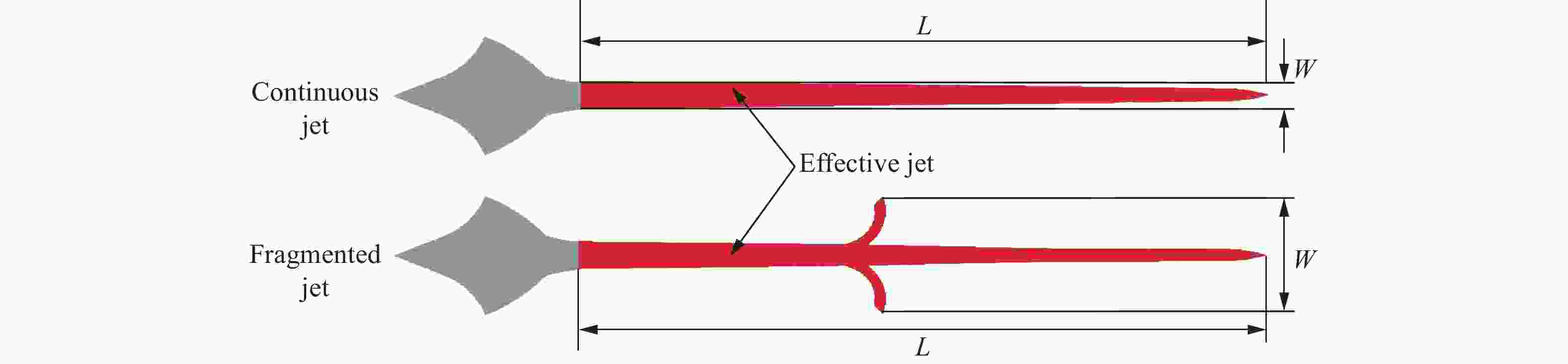

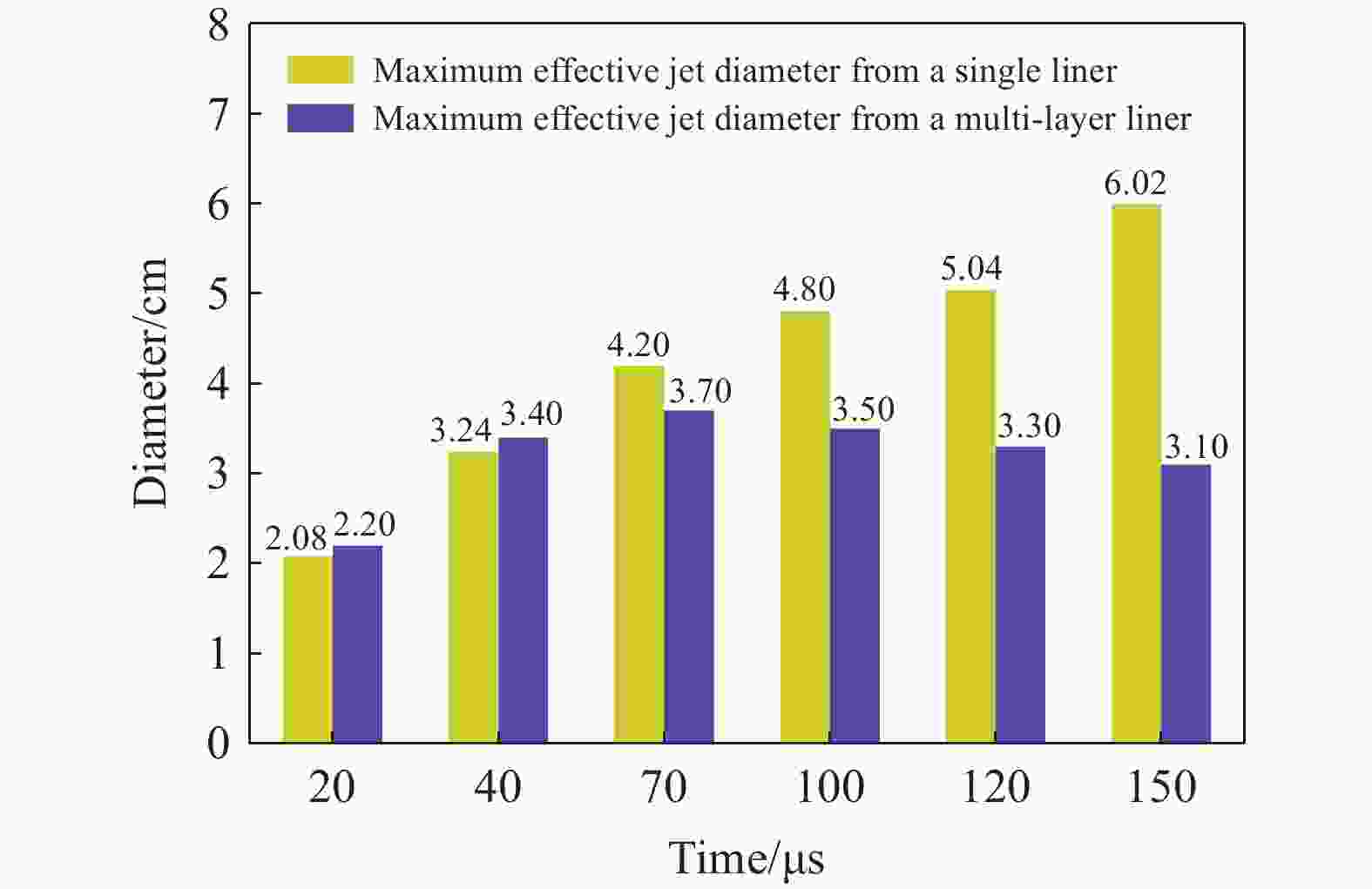

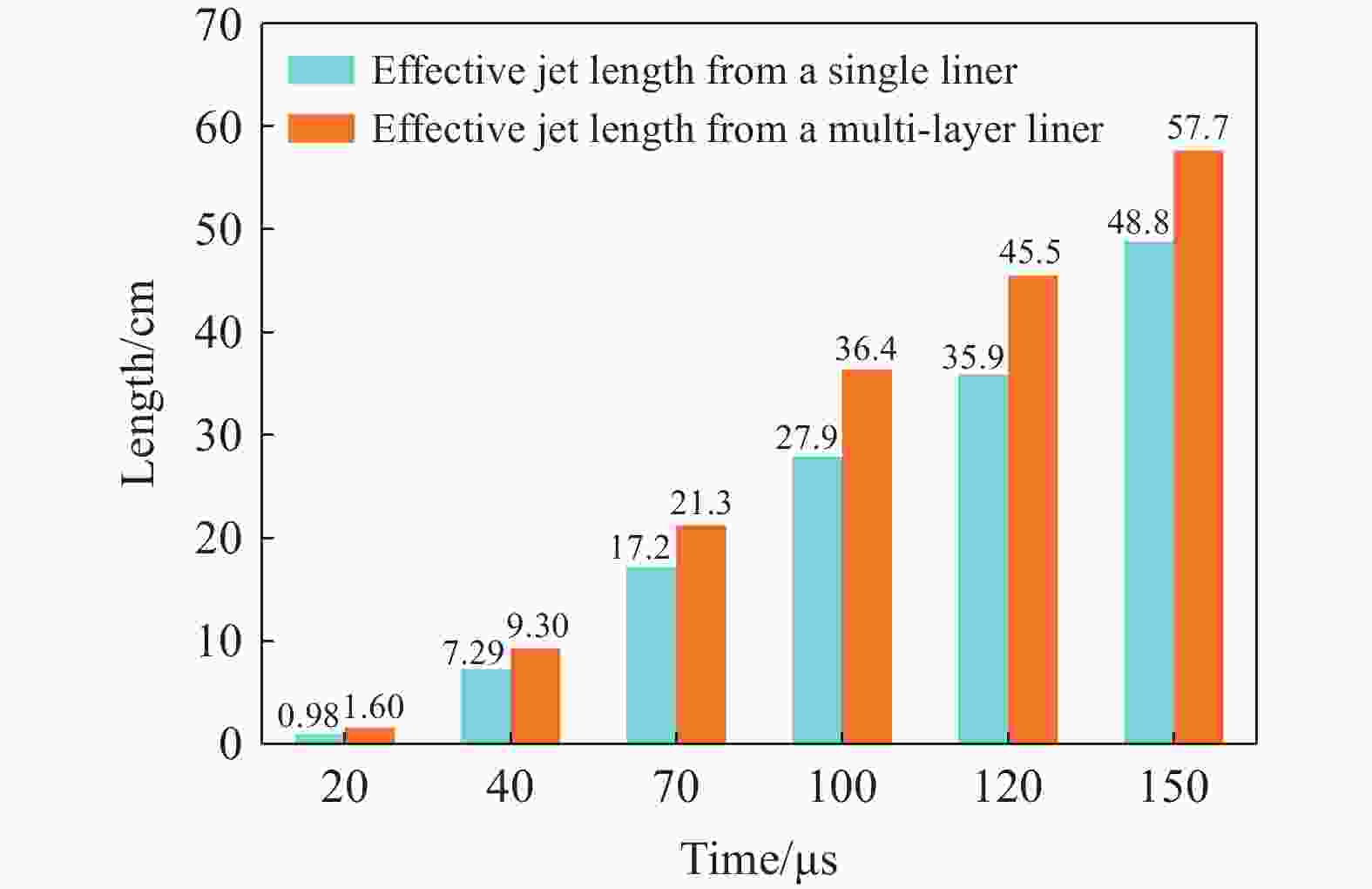

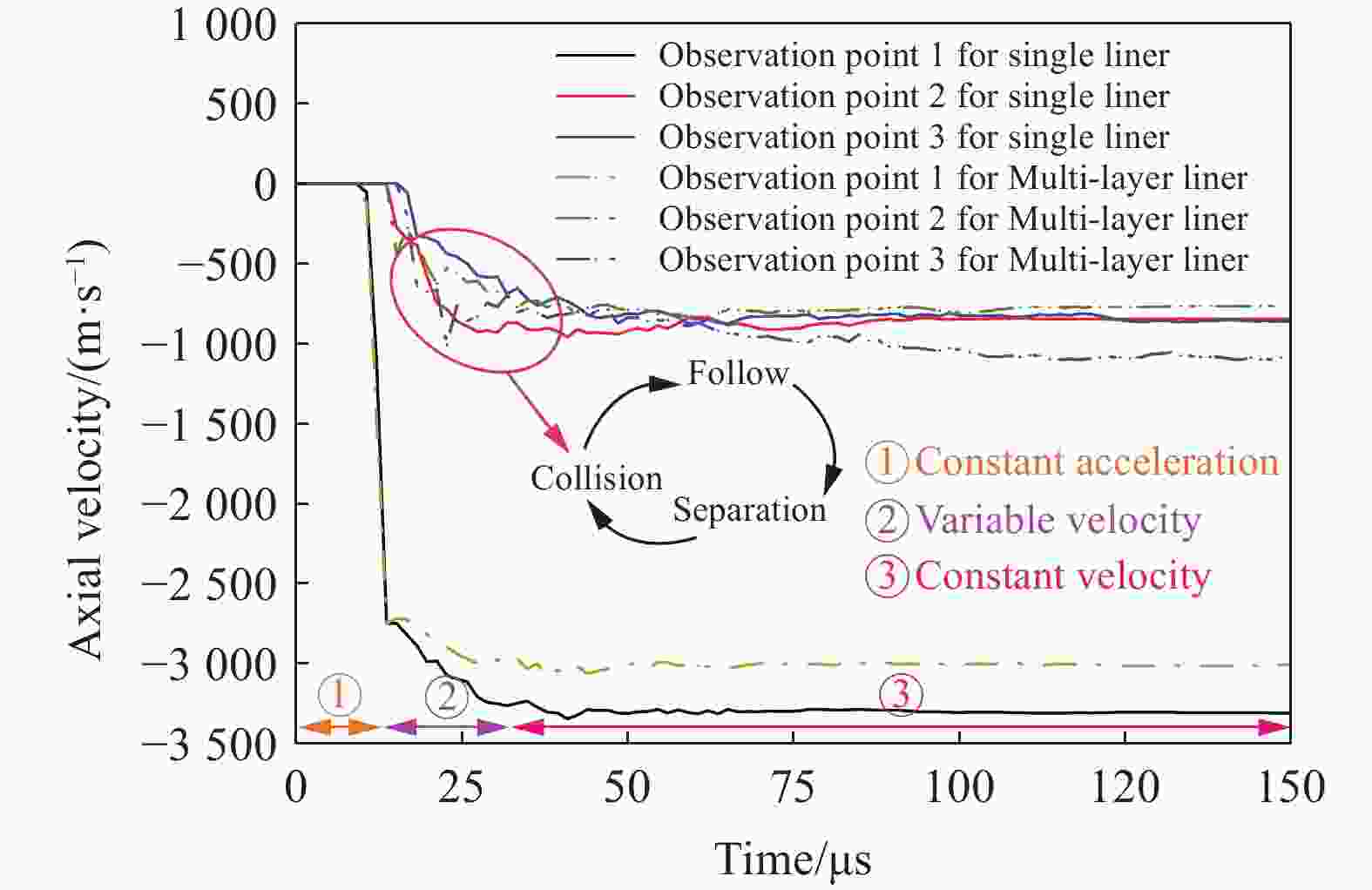

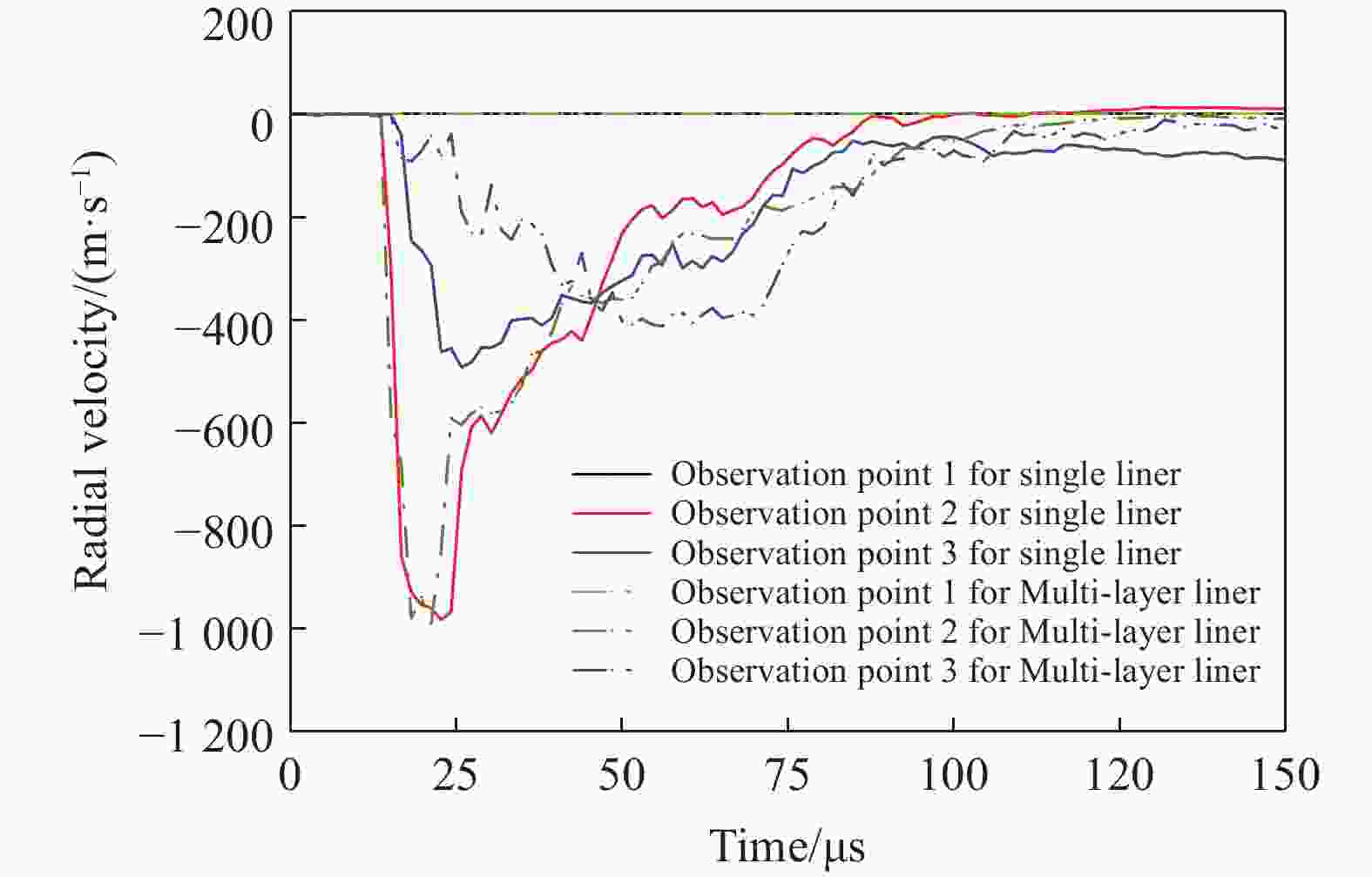

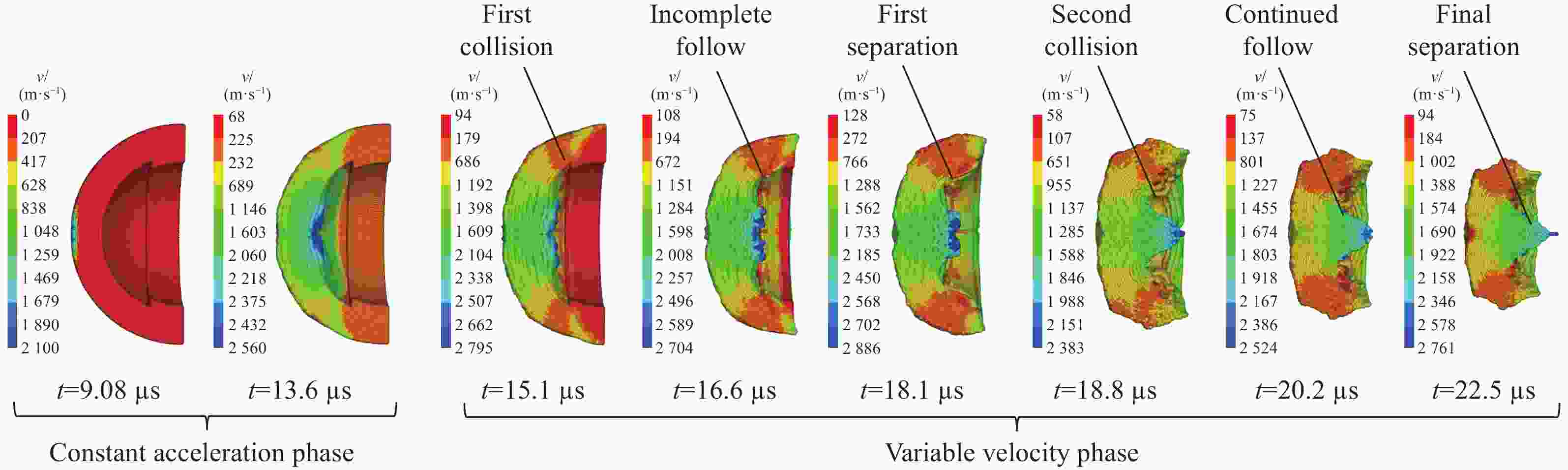

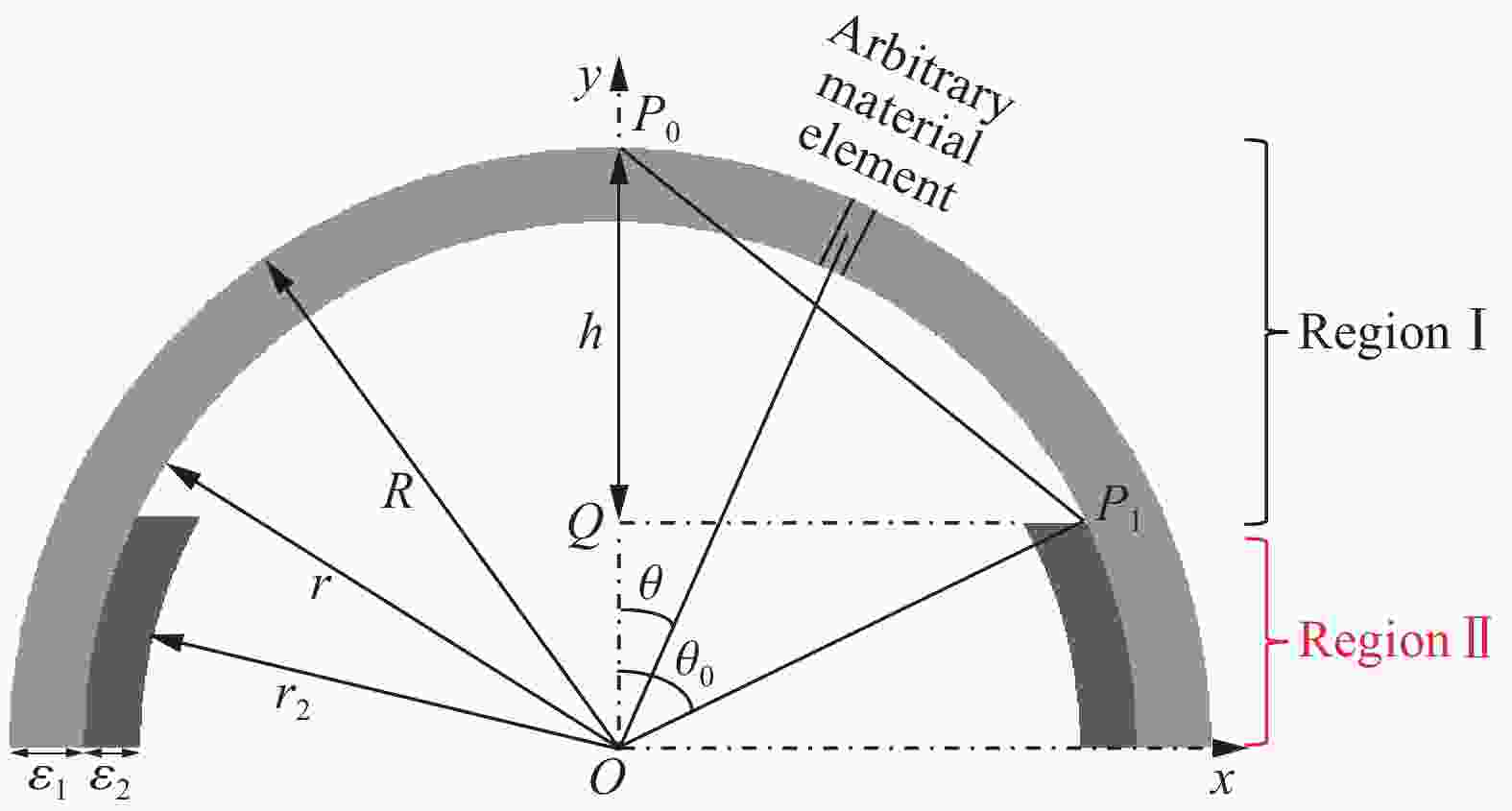

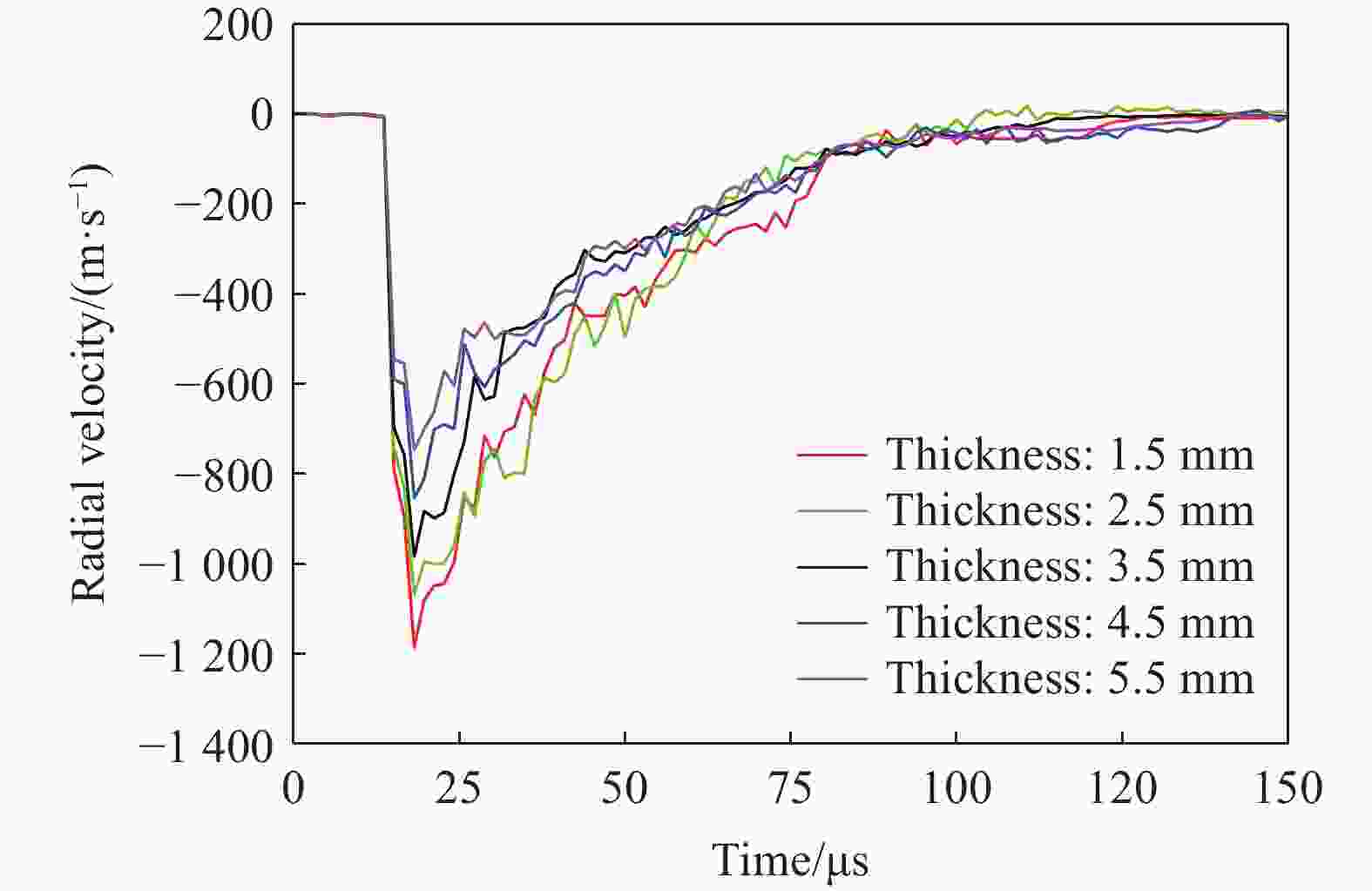

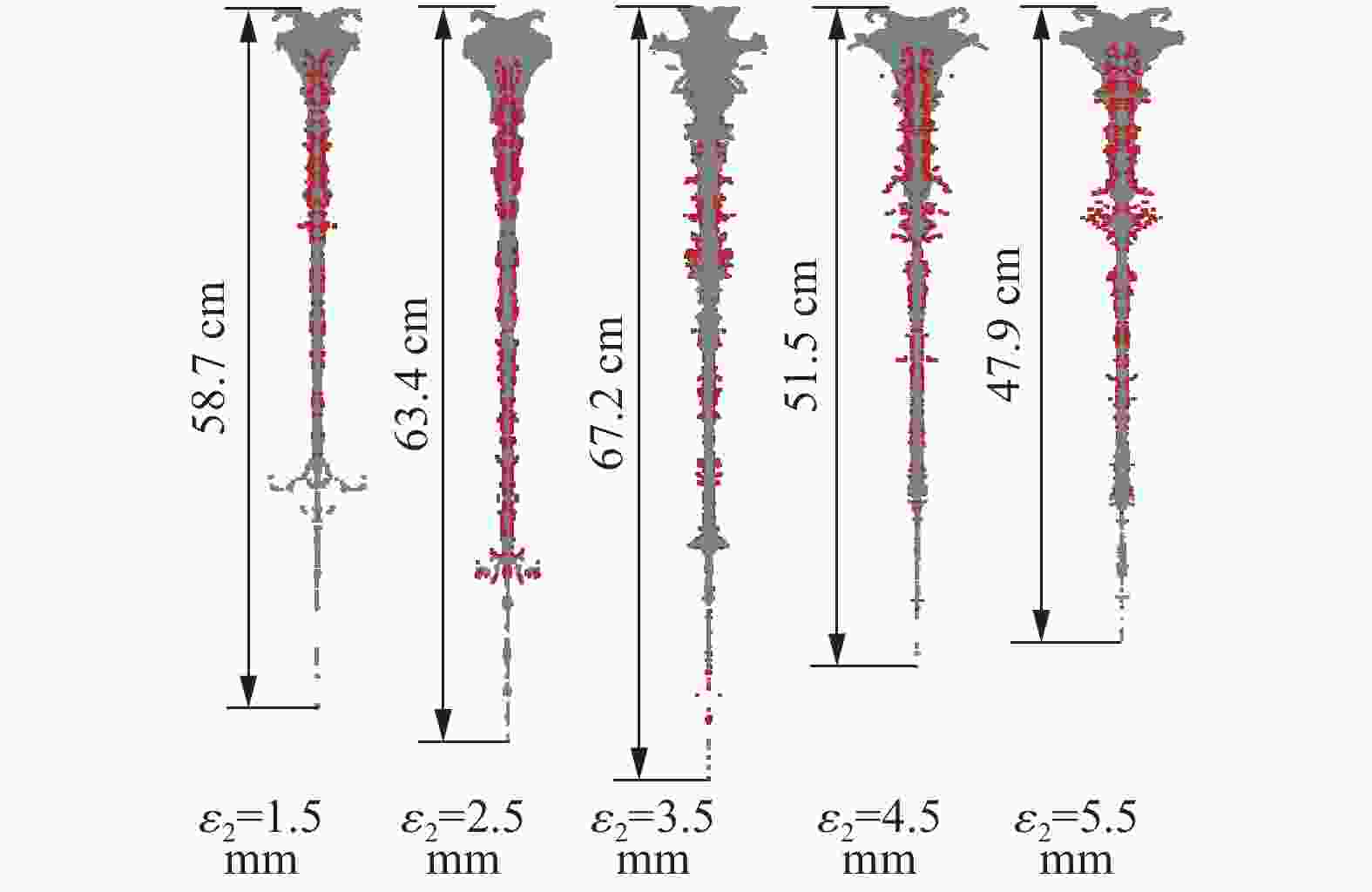

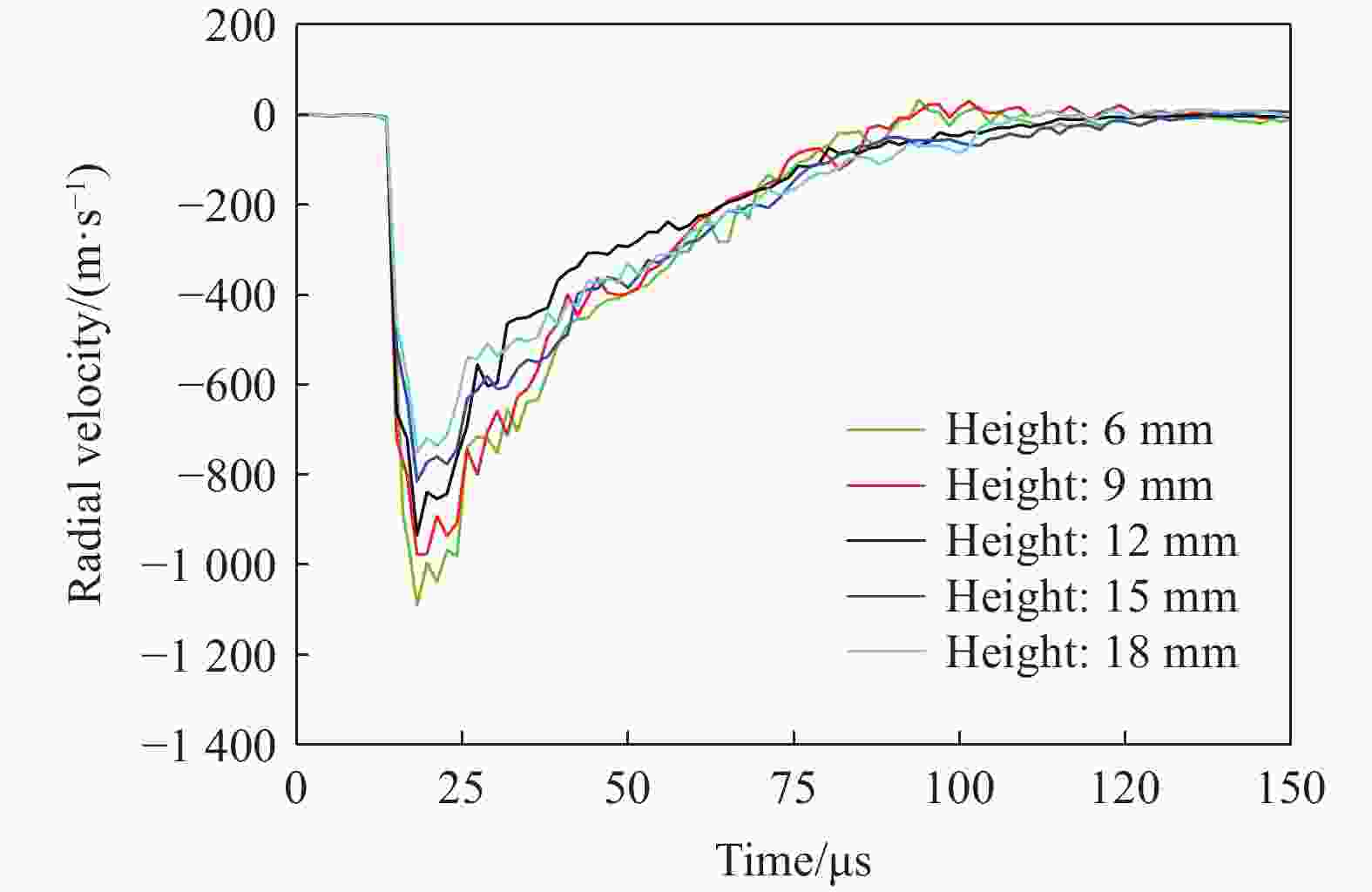

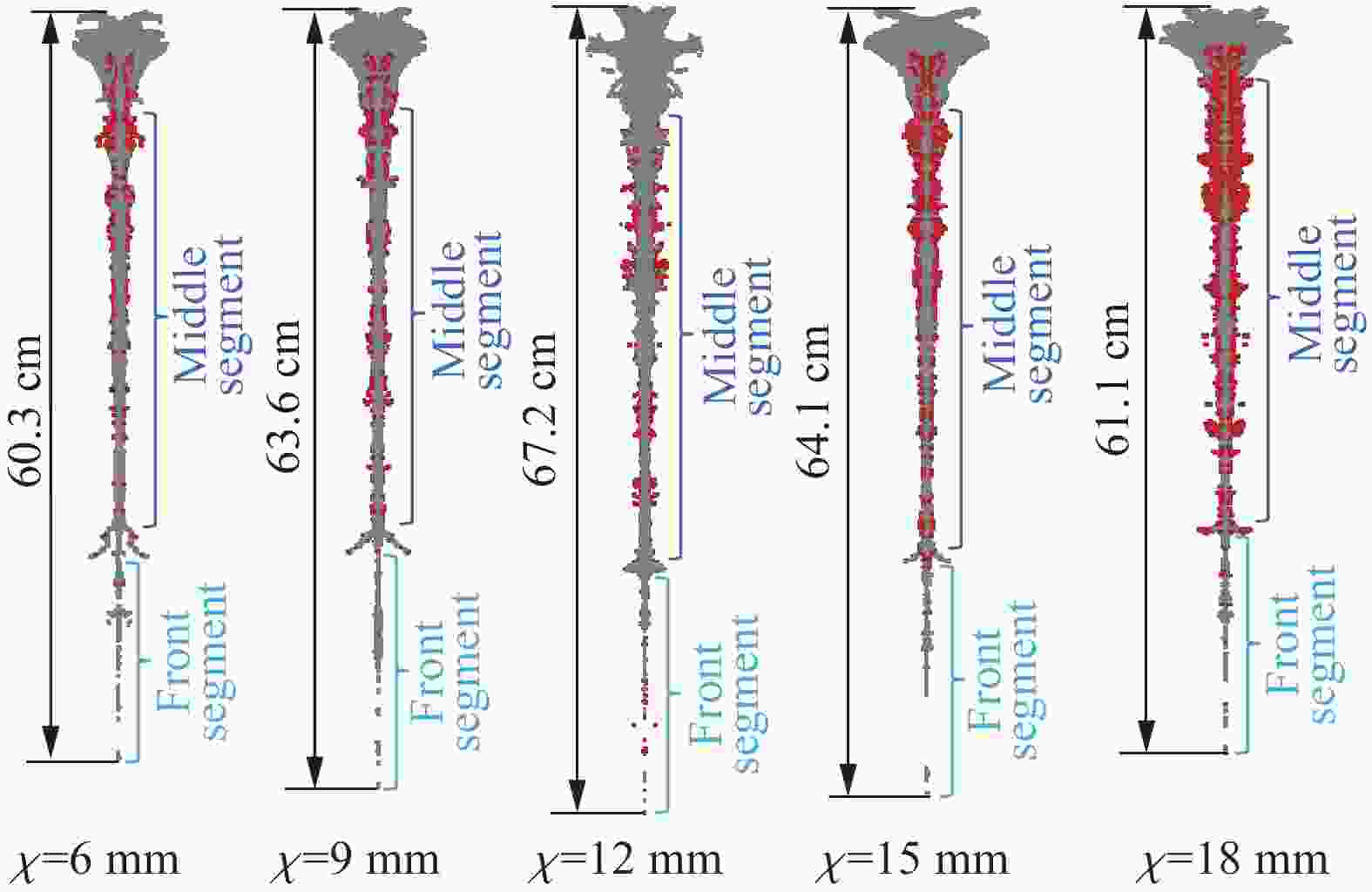

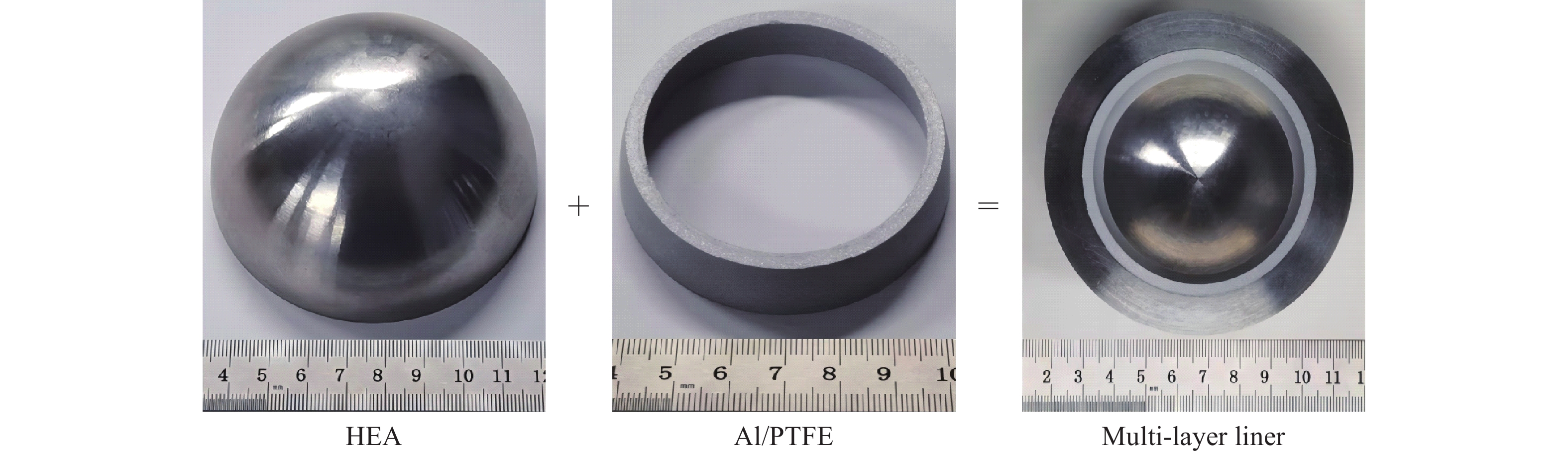

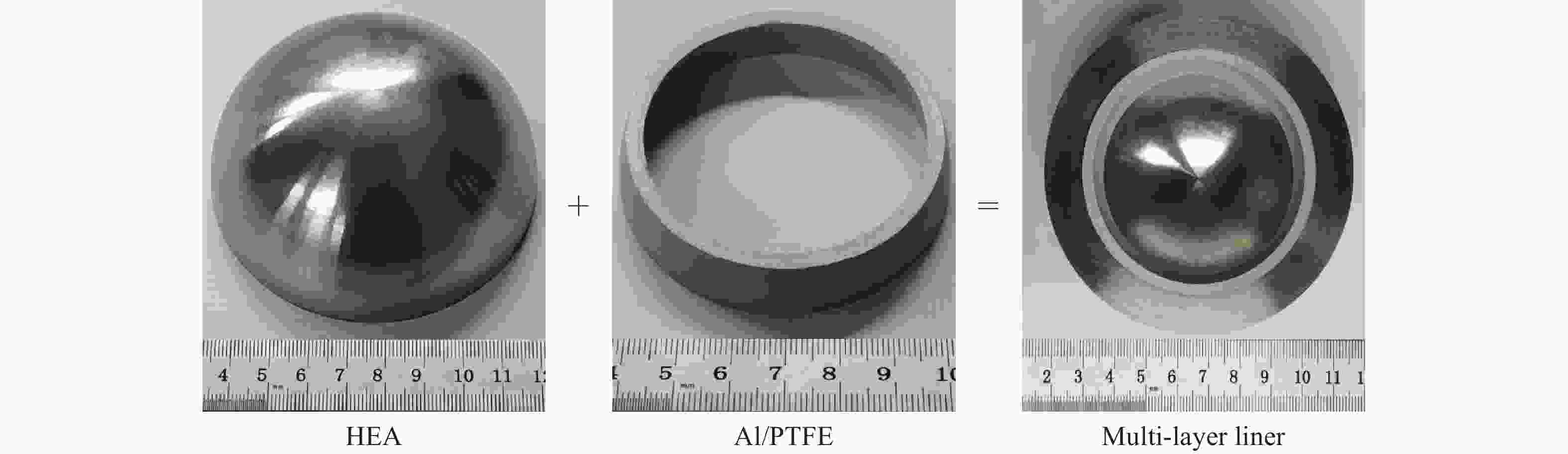

摘要: 针对传统金属射流在侵彻混凝土目标时存在毁伤面积有限、动态响应不足等问题,首次提出了一种新型高熵合金/铝/聚四氟乙烯(high-entropy alloys/aluminium/polytetrafluoroethylene,HEA/Al/PTFE)双层含能复合药型罩结构。采用真空电弧熔炼、粉末压制与烧结工艺,成功制备出带截顶内衬的半球形复合罩,并通过试验与数值模拟相结合的方法,系统研究了其成型机理、侵彻特性与毁伤效能。试验结果表明,相较于单层HEA罩,该复合结构能显著增强混凝土内部的碎裂和裂纹扩展能力,有效融合了HEA的优异力学性能与Al/PTFE的高能量释放特性。数值模拟表明,内衬对HEA射流具有抑制径向发散、提升射流中段凝聚性的“包覆”作用,但其多次碰撞-追随-分离行为也会延迟系统动态平衡。进一步建立了该复合罩分区成型理论模型,通过引入能量损失系数修正爆轰能量传递过程。通过理论预测结果与数值模拟结果的对比,形成的射流半径与杵体半径的误差小于15%。在此基础上分析了内衬厚度和高度对射流成型的影响规律,确定最优参数为厚度3.5 mm、高度12 mm,可在射流凝聚性、长度及毁伤威力之间实现最佳平衡。Abstract: Aiming at the limitations of traditional metal jets in penetrating concrete targets, such as limited damage range and insufficient dynamic response, a novel double-layer energetic composite liner structure with a truncated inner layer made of high-entropy alloys/aluminum/polytetrafluoroethylene (HEA/Al/PTFE) was proposed for the first time. The hemispherical composite liner’s HEA layer was prepared using vacuum arc melting, while the Al/PTFE inner layer was formed through powder compaction and sintering. To thoroughly verify the performance advantages of the composite liner, two types of shaped charge structures were fabricated during the experimental phase for comparison: one with the composite liner and the other with a single-layer HEA liner. C35 plain concrete cylinders were used as targets, with single-point initiation at the center of the charge top. Additionally, numerical simulations of the jet formation process were conducted using the commercial finite element software ANSYS-LS-DYNA. The explosive and liner were modeled with the Smoothed Particle Hydrodynamics (SPH) algorithm to accurately capture the dispersal behavior during jet formation, while the casing was simulated with the Lagrangian algorithm to describe the expansion and fragmentation process of the outer shell. In the simulation, the high-temperature and high-strain-rate mechanical behaviors of HEA, Al/PTFE, and 45 steel were described using the Johnson-Cook constitutive model. The explosive was modeled with the classical JWL equation of state, and air was treated as an ideal gas. All relevant parameters were sourced from published literature. Based on the axisymmetric curvature characteristics of the hemispherical liner and the material discontinuity introduced by truncation, a partitioned formation theoretical model was further established. An energy loss coefficient η (η = 0.2) was introduced to modify the detonation energy transfer process. According to the truncation angle θ0, the composite liner was divided into two regions with different physical mechanisms. The jet radius and slug radius for each region were derived using mass and momentum conservation. Experimental results show that both the composite liner and the single-layer HEA liner can form stable penetrating jets, achieving complete penetration of the concrete targets. Compared to the single-layer HEA liner, the composite structure significantly enhances the fragmentation and crack propagation capabilities inside the concrete. Numerical simulation results indicate that the Al/PTFE inner layer exhibits a “coating and cohesive” effect on the HEA jet, effectively suppressing radial dispersion and improving the continuity of the mid-section of the jet. However, multiple collision-following-separation behaviors between the inner layer and the main jet delay the system from reaching dynamic equilibrium. The established partitioned formation theoretical model demonstrates good predictive accuracy, with relative errors of less than 15% between the predicted jet and slug radii and the numerical simulation results. Further parametric analysis reveals that the thickness and height of the inner layer significantly influence jet formation. The optimal parameter combination is a thickness of 3.5mm and a height of 12mm, which achieves the best balance between suppressing radial dispersion, maintaining jet length, and enhancing mid-section cohesion. This composite liner effectively integrates the excellent mechanical properties of HEA with the high energy release characteristics of Al/PTFE. The established partitioned formation theoretical model provides a reliable theoretical basis for the design of hemispherical composite liners. The research findings offer important theoretical and experimental support for the optimized design and engineering application of novel energetic composite liners.

-

Key words:

- high-entropy alloys /

- Al/PTFE /

- composite liner /

- forming

-

表 1 混凝土的毁伤结果对比

Table 1. Comparison of concrete damage results

试验工况 D1/cm d/cm H1/cm D2/cm H2/cm 复合结构 48.1 7.6 10.3 50.4 17.3 单HEA 61.8 5.8 15.0 65.6 17.3 Ae/GPa Be/GPa R1 R2 ω E0/GPa 630 6.801 4.1 1.3 0.36 10 ρa/(kg·m−3) C0~C3 C4 C5 E1/kPa V0 1.225 0 0.4 0.4 250 1.0 表 5 理论预测结果与数值模拟结果对比

Table 5. Comparison between theoretical predictions and numerical simulation results

参数 理论预测值/cm 数值模拟值/cm 相对误差/% Aj 1.72 1.55 10.97 As 2.45 2.23 9.87 -

[1] ZHENG H L, WANG Z X, WANG M Y, et al. Research on jet formation and penetration enhancement of spherical-segment lightweight high-entropy alloy liners against finite-thickness reinforced concrete [J]. Structures, 2025, 80: 109814. DOI: 10.1016/j.istruc.2025.109814. [2] 王岩鑫. PTFE/Al活性聚能射流成形机制研究[D]. 太原: 中北大学, 2023: 1–2. DOI: 10.27470/d.cnki.ghbgc.2023.001005.WANG Y X. Research on the jet formation mechanism of PTFE/Al reactive shaped charge [D]. Taiyuan: North University of China, 2023: 1–2. DOI: 10.27470/d.cnki.ghbgc.2023.001005. [3] 郭焕果, 卢冠成, 何所, 等. 活性复合罩聚能装药侵彻增强行为 [J]. 北京理工大学学报, 2020, 40(12): 1259–1266. DOI: 10.15918/j.tbit1001-0645.2019.247.GUO H G, LUO G C, HE S, et al. Penetration enhancement behavior of reactive material double-layered liner shaped charge [J]. Transactions of Beijing Institute of Technology, 2020, 40(12): 1259–1266. DOI: 10.15918/j.tbit1001-0645.2019.247. [4] BAKER E L, DANIELS A S, NG K W, et al. Barnie: a unitary demolition warhead [C]// Proceedings of the 19th International Symposium on Ballistics. Interlaken, Switzerland: International Ballistics Committee, 2001: 569–574. [5] DANIELS A S, BAKER E L, DEFISHER S E, et al. Bam bam: large scale unitary demolition warheads [C]// Proceedings of the 23th International Symposium on Ballistics. Tarragona, Spain, 2007: 125–130. [6] DANIELS A S, BAKER E L, NG K W. A unitary demolition warhead [C]//US Army. Picatinny Arsenal, Mines. Demolition and Non-lethal Weapons Conference. New Orleans, LA, 2003: 9–11. [7] WANG Y Z, YU Q B, ZHENG Y F, et al. Formation and penetration of jets by shaped charges with reactive material liners [J]. Propellants, Explosives, Pyrotechnics, 2016, 41(4): 618–622. DOI: 10.1002/prep.201500298. [8] 张雪朋, 肖建光, 余庆波, 等. 活性药型罩聚能装药破甲后效超压特性 [J]. 兵工学报, 2016, 37(8): 1388–1394. DOI: 10. 3969/j. issn. 1000-1093. 2016. 08. 007. DOI: 10.3969/j.issn.1000-1093.2016.08.007.ZHANG X P, XIAO J G, YU Q B, et al. Armor penetration aftereffect overpressure produced by reactive material liner shaped charge [J]. Acta Armamentarii, 2016, 37(8): 1388–1394. DOI: 10.3969/j.issn.1000-1093.2016.08.007. [9] YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes [J]. Advance Engineering Materials, 2004, 6: 299–303. DOI: 10.1002/adem.200300567. [10] JIANG L H, LIU X G, GUO Z H, et al. Effect of high strain rate on adiabatic shear susceptibility and microstructures in Al0.4CoCrFeNi high-entropy alloy [J]. Journal of Materials Research and Technology, 2024, 31: 2003–2013. DOI: 10.1016/j.jmrt.2024.06.177. [11] 李嘉伟. 药型罩用CoCrFeNiWx高熵合金的本构参数及破甲模拟研究 [D]. 太原: 太原理工大学, 2024: 5. DOI: 10.27352/d.cnki.gylgu.2024.002609.LI J W. Constitutive parameters and armor-piercing simulation of CoCrFeNiWx high-entropy alloy for shaped charge liner [D]. Taiyuan: Taiyuan University of Science and Technology, 2024: 5. DOI: 10.27352/d.cnki.gylgu.2024.002609. [12] KUMAR D, SEETHARAM R, PONAPPA K. A review on microstructures, mechanical properties and processing of high entropy alloys reinforced composite materials [J]. Journal of Alloys and Compounds, 2024, 972: 172732. DOI: 10.1016/j.jallcom.2023.172732. [13] JING Q M, HU L, LI J, et al. Significant strength enhancement of high-entropy alloy via phase engineering and lattice distortion [J]. Journal of Alloys and Compounds, 2024, 976: 172963. DOI: 10.1016/j.jallcom.2023.172963. [14] LI R X, BIAN B X, WILD G, et al. Bulk and grain boundary tracer diffusion in multiphase AlCoCrFeNiTi0.2 compositionally complex alloy [J]. Acta Materialia, 2023, 261: 119352. DOI: 10.1016/j.actamat.2023.119352. [15] WANG L, ZHANG L T, LU X, et al. Surprising cocktail effect in high entropy alloys on catalyzing magnesium hydride for solid-state hydrogen storage [J]. Chemical Engineering Journal, 2023, 465: 142766. DOI: 10.1016/j.cej.2023.142766. [16] 刘承哲, 王海福, 张甲浩, 等. 轻质高熵合金聚能射流毁伤混凝土靶行为研究 [J]. 兵工学报, 2024, 45(S1): 60–69. DOI: 10.12382/bgxb.2024.0642.LIU C Z, WANG H F, ZHANG J H, et al. Research on behavior of lightweight high-entropy alloy jet penetrating concrete targets [J]. Acta Armamentarii, 2024, 45(S1): 60–69. DOI: 10.12382/bgxb.2024.0642. [17] 鄢阿敏, 乔禹, 戴兰宏. 高熵合金药型罩射流成型与稳定性 [J]. 力学学报, 2022, 54(8): 2119–2130. DOI: 10.6052/0459-1879-22-274.YAN A M, QIAO Y, DAI L H. Formation and stability of shaped charge liner jet of CrMnFeCoNi high-entropy alloy [J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(8): 2119–2130. DOI: 10.6052/0459-1879-22-274. [18] LI R X, DING J B, ZHAO Y Y, et al. Preliminary study on the dynamic deformation mechanism of CoCrFeNi high-entropy alloy and its application in the shaped charge liner [J]. Journal of Alloys and Compounds, 2024, 999: 175083. DOI: 10.1016/j.jallcom.2024.175083. [19] LI R X, WANG R Q, TIAN Q W, et al. An investigation on the jet formation and penetration characteristics of the CuCoCrFeNi high-entropy alloy liner [J]. AIP Advances, 2024, 14: 055017. DOI: 10.1063/5.0207709. [20] WANG X T, WANG B P, LIU X D, et al. Asynchronous deformation behavior of precipitation-hardened high-entropy alloys shaped charge liner under explosive loading [J]. Intermetallics, 2025, 176: 108555. DOI: 10.1016/j.intermet.2024.108555. [21] LI R X, CHEN J L, WANG R Q, et al. Performance study of explosively formed projectile using CoCrFeNi high-entropy alloy as a liner [J]. Journal of Applied Physics, 2024, 136: 145901. DOI: 10.1063/5.0231905. [22] LIU C Z, ZHENG Y F, ZHANG J H, et al. Experimental and numerical investigation of lightweight high-entropy alloys shaped charge jet and its penetration performance [J]. International Journal of Impact Engineering, 2026, 208: 105512. DOI: 10.1016/j.ijimpeng.2025.105512. [23] 郑宇. 双层药型罩毁伤元形成机理研究 [D]. 南京: 南京理工大学, 2008: 12.ZHENG Y. Study on the formation mechanism of kill element from shaped charge with double layer liners [D]. Nanjing: Nanjing University of Science and Technology, 2008: 12. [24] 辛广华, 杨宝良, 景彤, 等. 双层罩轴向组合式装药结构MEFP数值模拟 [J]. 弹箭与制导学报, 2023, 43(6): 19–28. DOI: 10.15892/j.cnki.djzdxb.2023.06.004.XIN G H, YANG B L, JING T, et al. Numerical simulation of MEFP for axial combined charge structures with double layer liners [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2023, 43(6): 19–28. DOI: 10.15892/j.cnki.djzdxb.2023.06.004. [25] 刘猛, 马铎, 单海江, 等. 基于正交优化的双层双锥形药型罩结构设计[J/OL]. 兵器材料科学与工程, 2025. DOI: 10. 14024/j.cnki. 1004-244x. 20250519. 007.LIU M, MA D, SHAN H J, et al. Design of a double-layer biconical liner structure based on orthogonal optimization [J]. Ordnance Material Science and Engineering, 2025. DOI: 10.14024/j.cnki.1004-244x.20250519.007. [26] 李昊, 尹建平, 毕广剑, 等. 截顶辅助双层药型罩射流成型影响研究 [J]. 兵器装备工程学报, 2022, 43(4): 31–35. DOI: 10.11809/bqzbgcxb2022.04.006.LI H, YIN J P, BI G J, et al. Study on influence of top-cutting assisted double-layer liner jet forming [J]. Journal of Ordnance Equipment Engineering, 2022, 43(4): 31–35. DOI: 10.11809/bqzbgcxb2022.04.006. [27] 黄炳瑜, 熊玮, 张先锋, 等. 双层含能药型罩K装药射流成型及侵彻性能试验 [J]. 含能材料, 2021, 29(2): 149–156. DOI: 10.11943/CJEM2020231.HUANG B Y, XIONG W, ZHANG X F, et al. Experimental study on jet formation and penetration performance of double-layered reactive liners with k-charge [J]. Chinese Journal of Energetic Materials, 2021, 29(2): 149–156. DOI: 10.11943/CJEM2020231. [28] ZHENG H L, WANG Z X, WANG M Y, et al. Study on mechanical response and penetration mechanism of lightweight BCC high-entropy alloy (Ti2Zr)1.5NbVAl0.5 under extreme dynamic loads [J]. Intermetallics, 2025, 186: 108966. DOI: 10.1016/j.intermet.2025.108966. [29] ZHENG H L, WANG Z X, LI Z K, et al. Study on deformation mechanism and energy release characteristics of refractory high-entropy alloy (Ti2Zr)1.5NbVAl0.5 under different loading conditions [J]. Journal of Alloys and Compounds, 2025, 1018: 179031. DOI: 10.1016/j.jallcom.2025.179031. [30] 周鑫, 冯彬, 陈力, 等. 活性射流侵彻-内爆作用下半无限混凝土靶中应力波效应 [J]. 含能材料, 2025, 33(7): 689–702. DOI: 10.11943/CJEM2025079.ZHOU X, FENG B, CHEN L, et al. Stress wave effect in semi-infinite concrete targets subjected to penetration-implosion action of reactive jet [J]. Chinese Journal of Energetic Materials, 2025, 33(7): 689–702. DOI: 10.11943/CJEM2025079. [31] HAO L K, GU W B, ZHANG Y D, et al. Damage of a large-scale reinforced concrete wall caused by an explosively formed projectile (EFP) [J]. Defence Technology, 2023, 28: 280–297. DOI: 10.1016/j.dt.2022.11.003. [32] LI W B, WANG X M, LI W B, et al. The effect of annular multi-point initiation on the formation and penetration of an explosively formed penetrator [J]. International Journal of Impact Engineering, 2010, 37: 414–424. DOI: 10.1016/j.ijimpeng.2009.08.008. [33] SUN S J, JIANG J W, WANG S Y, et al. Structural design of the fluted shaped charge liner using multi-section optimization method [J]. Defence Technology, 2023, 25: 249–262. DOI: 10.1016/j.dt.2023.01.008. -

下载:

下载: