Implementation of metallic material constitutive models based on artificial neural networks in explicit finite element analysis

-

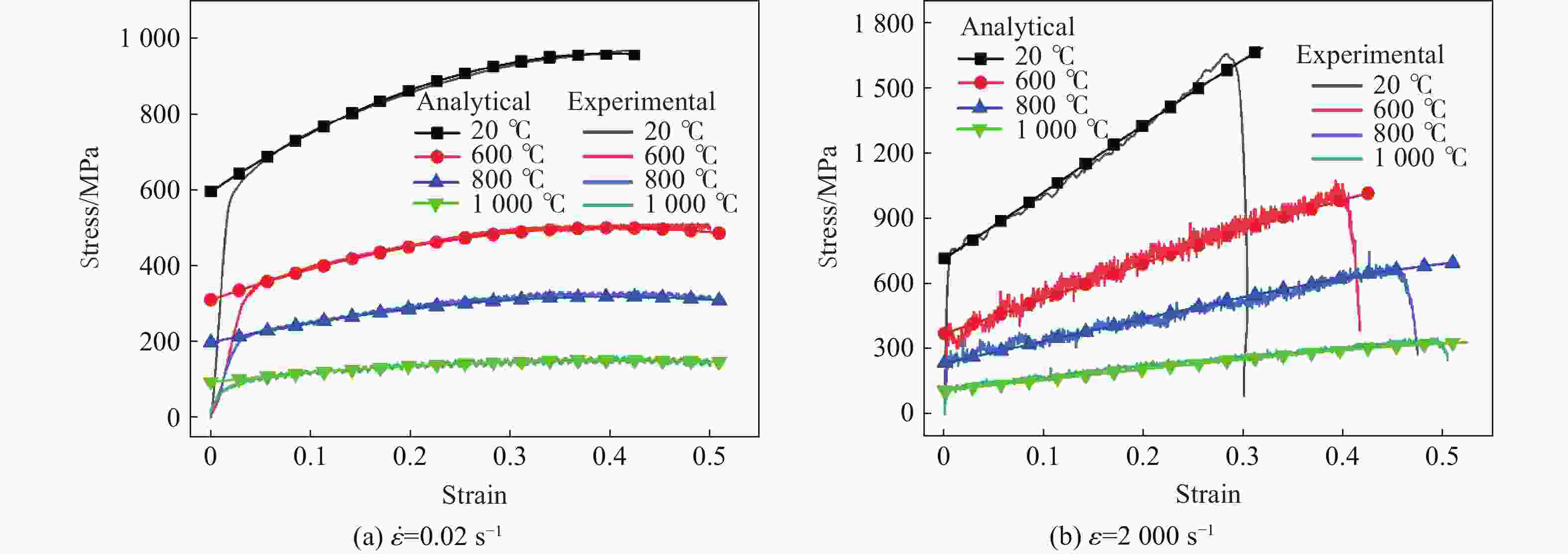

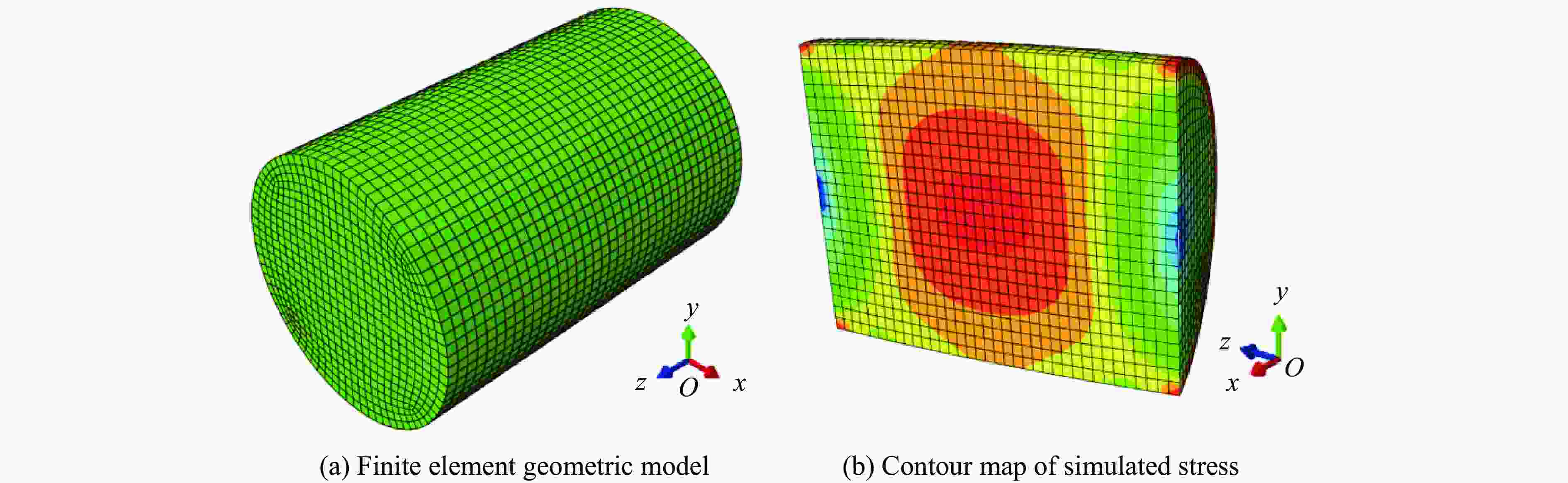

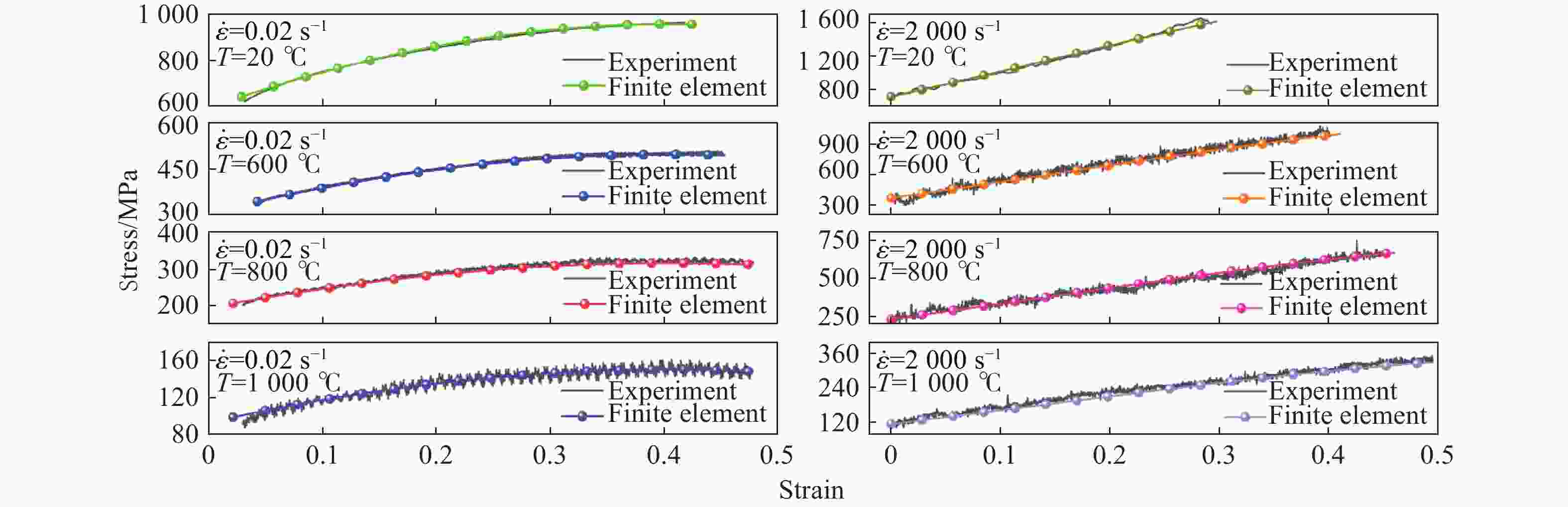

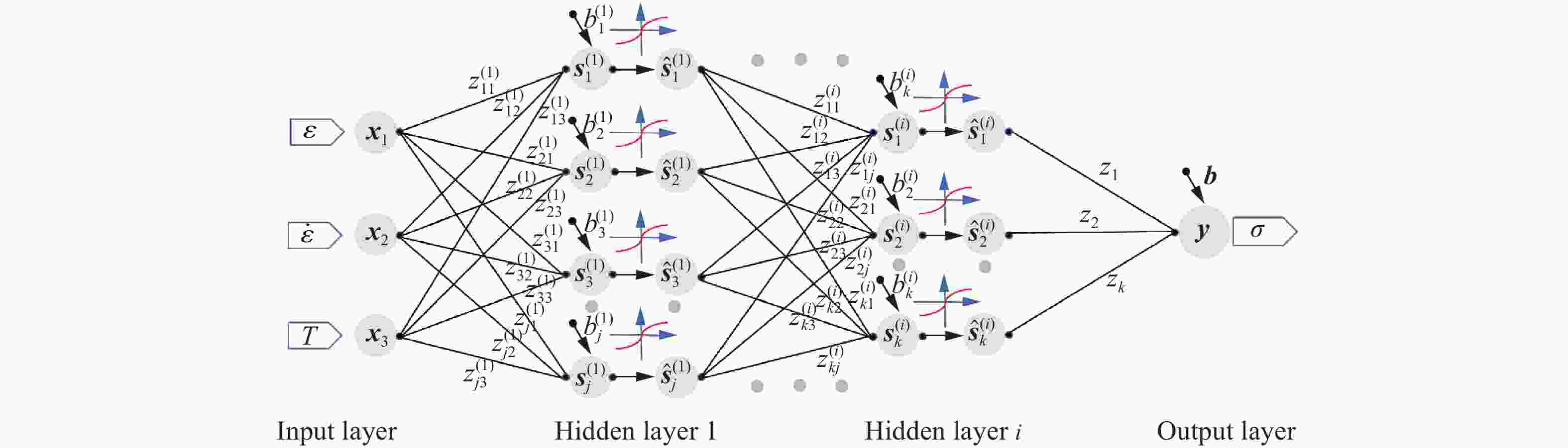

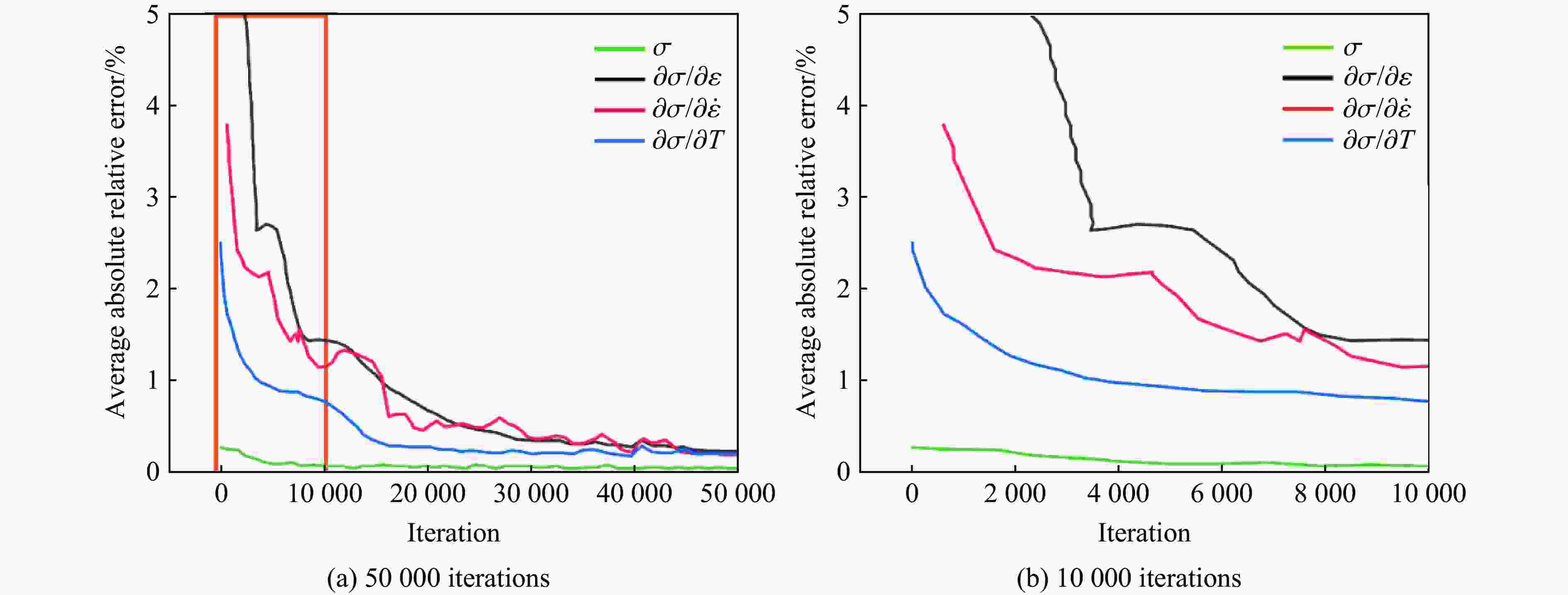

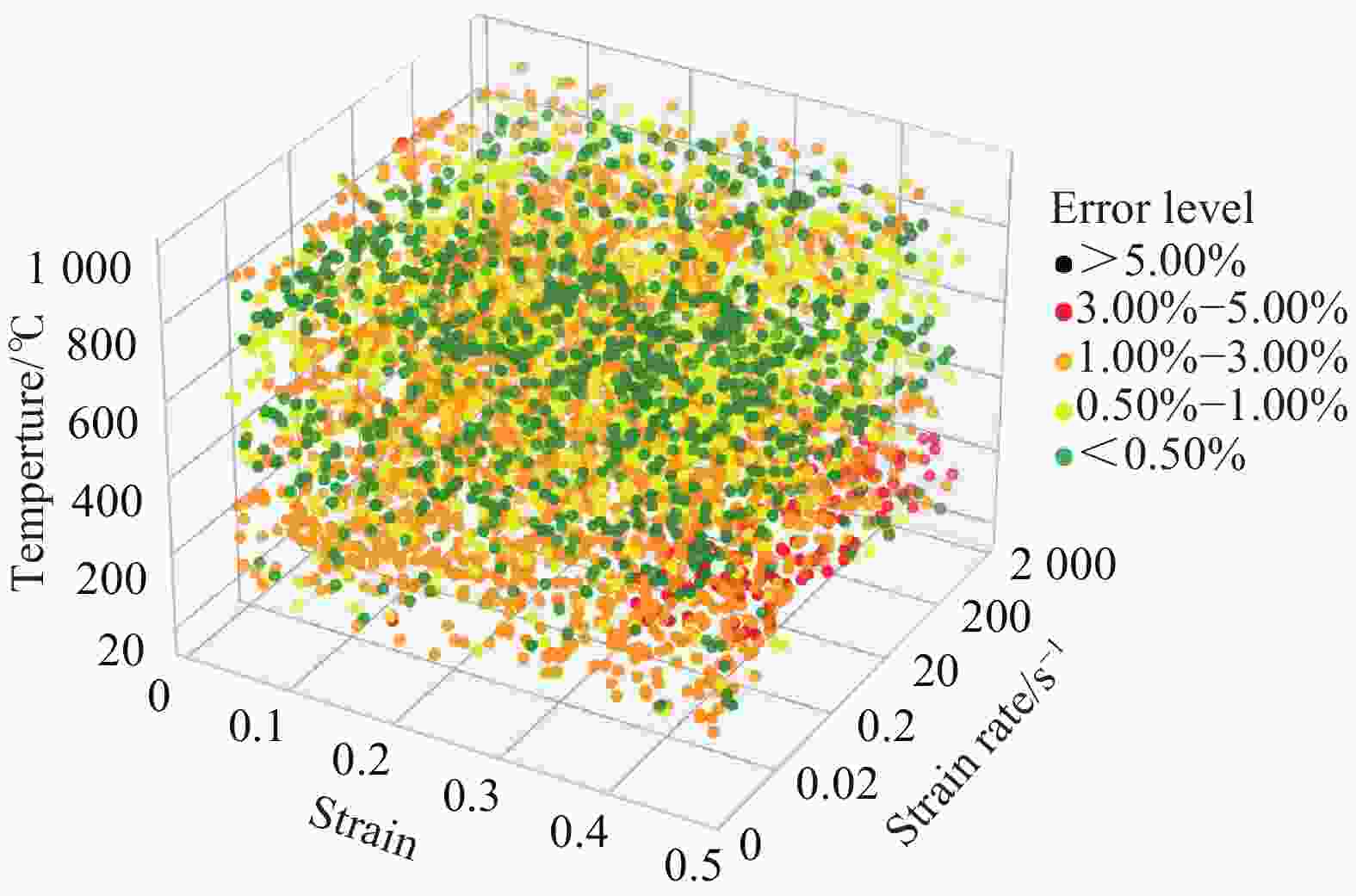

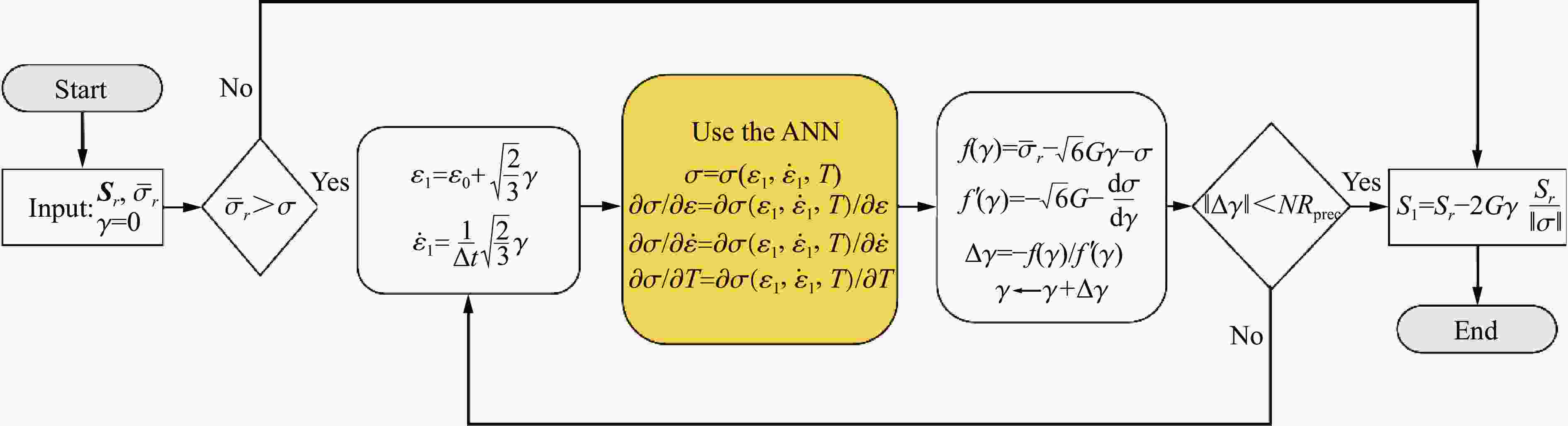

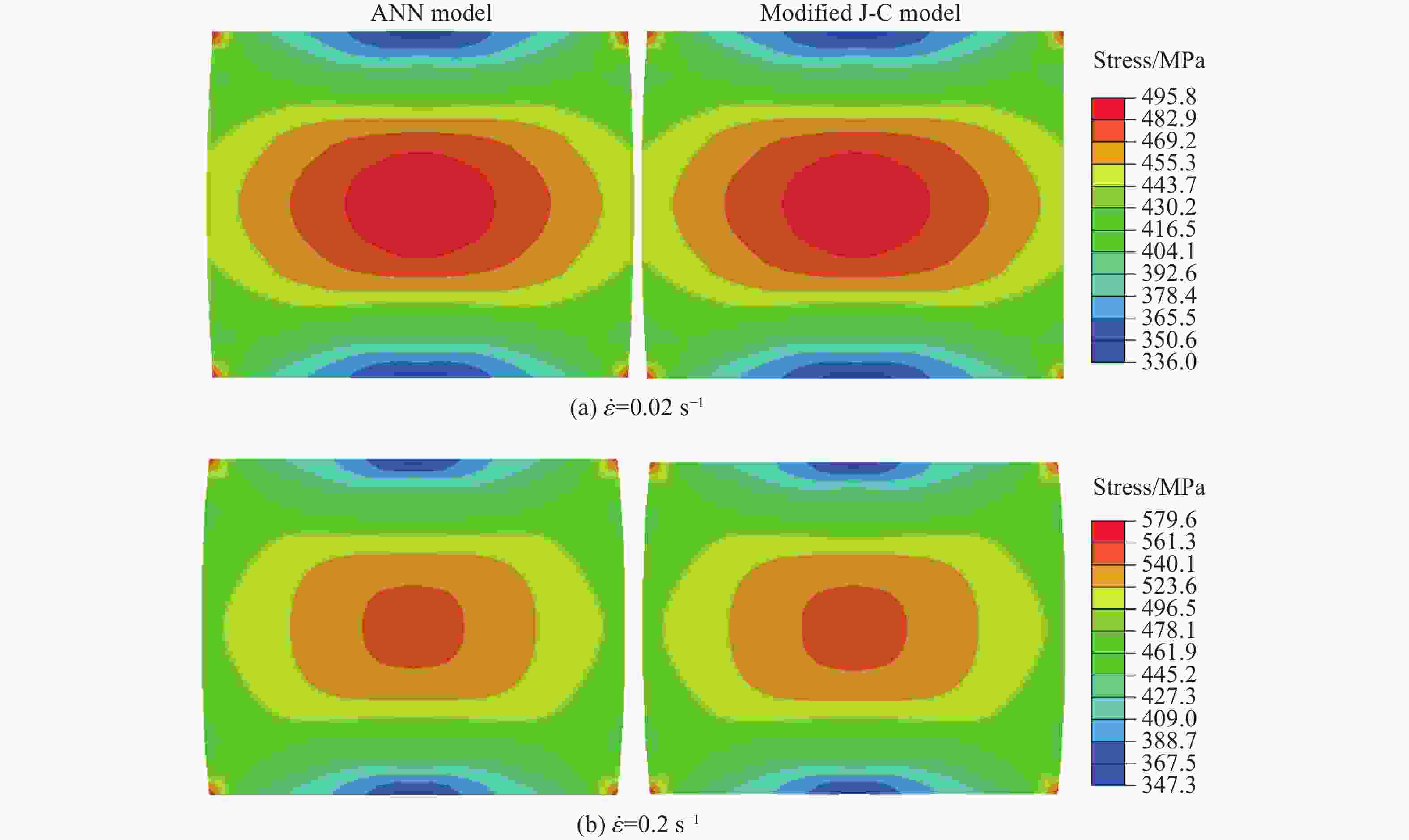

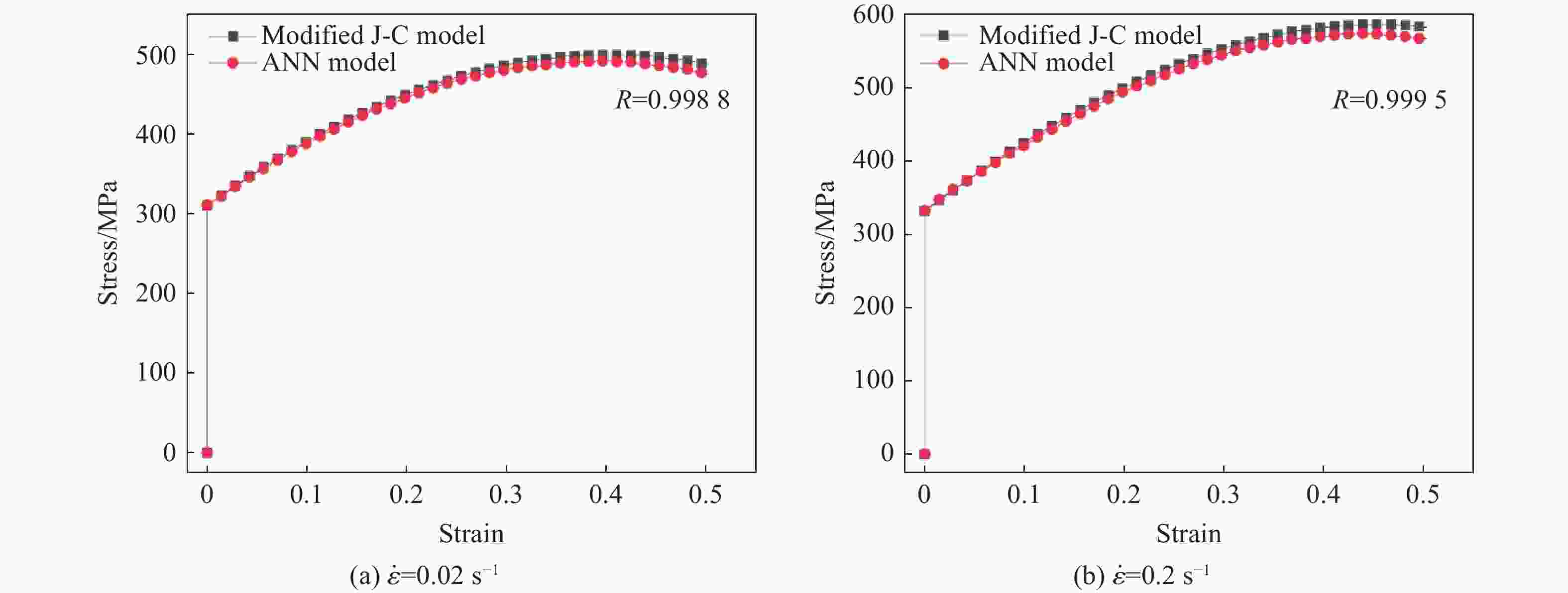

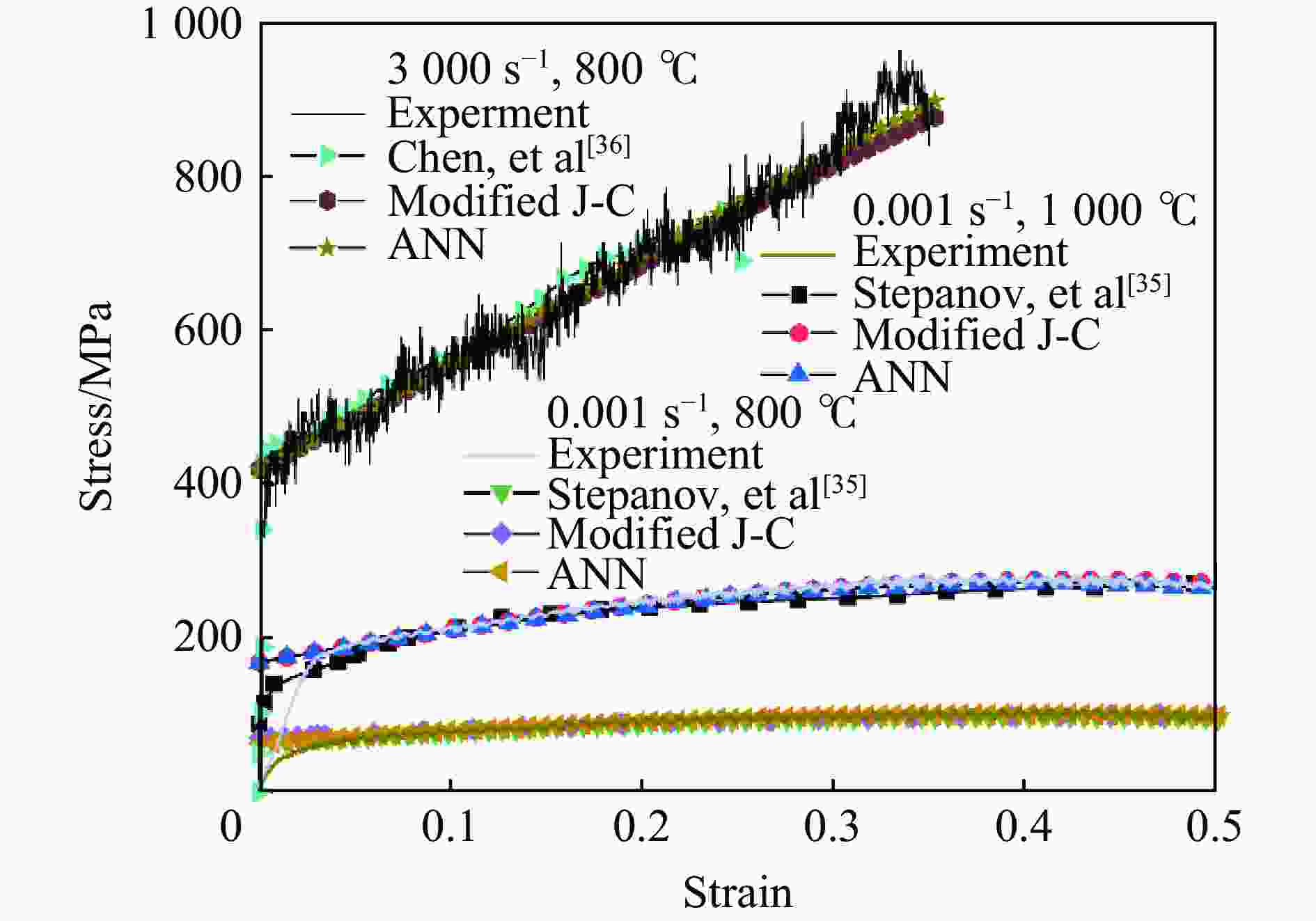

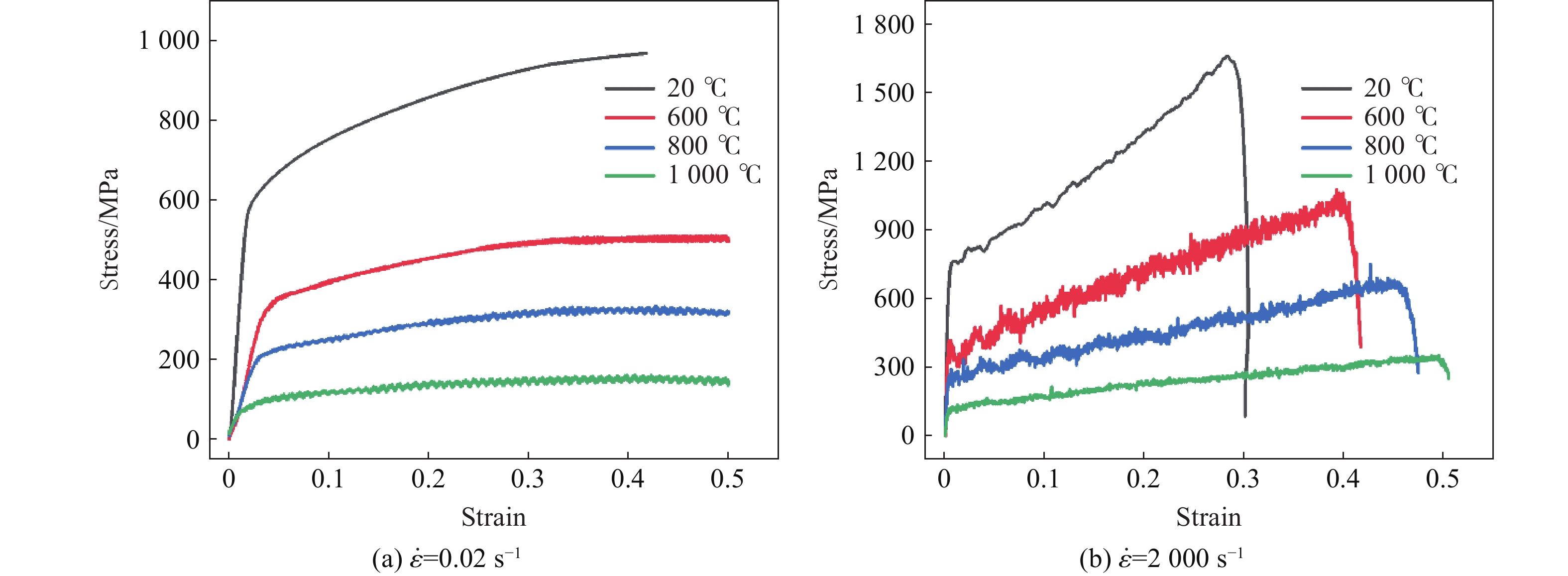

摘要: 以CoCrFeNiMn高熵合金为研究对象,首先开展了不同温度与应变率下的压缩实验,获得了应力-应变数据;随后基于实验结果建立了修正的Johnson-Cook本构模型,并用于有限元仿真生成机器学习训练数据。在此基础上构建人工神经网络(artificial neural network, ANN)模型,对材料流动应力进行学习与预测。为实现神经网络在有限元框架中的高效应用,开发了基于FORTRAN的自动代码生成工具,将训练完成的ANN模型嵌入到Abaqus/Explicit计算平台中。结果表明,该方法预测精度高,相对误差低于1%,且计算效率优于传统本构模型。基于数据驱动的神经网络方法可有效替代传统本构模型在有限元中的应用,为金属材料的数值建模与模拟提供了一条有效路径。Abstract: Machine learning techniques have been increasingly applied to the prediction of material behavior and have demonstrated clear advantages over conventional constitutive modeling approaches. The objective of this study was to develop an accurate and computationally efficient data-driven constitutive description for metallic materials under coupled temperature and strain-rate loading conditions. A CoCrFeNiMn high-entropy alloy was selected as the representative material system.Compression experiments were performed over a wide range of temperatures and strain rates to obtain true stress-strain data. Based on the experimental results, a modified Johnson-Cook constitutive model was calibrated to describe strain hardening, strain-rate sensitivity, and thermal softening effects. The calibrated model was then implemented in finite element simulations to generate a large, physically consistent dataset spanning broad thermo-mechanical conditions. This simulation-assisted data generation strategy expanded the training domain while ensuring continuity and stability of the dataset. Using the generated data, an artificial neural network (ANN) model was constructed to learn the nonlinear relationship between strain, strain rate, temperature, and flow stress. The network architecture and training strategy were optimized to improve prediction accuracy and generalization performance. To enable efficient application of the trained ANN within an explicit finite element framework, an automatic FORTRAN code generation tool was developed. The trained ANN parameters were converted into a user-defined material subroutine and embedded into the Abaqus/Explicit platform, allowing direct numerical implementation without external dependencies.The results indicate that the ANN-based constitutive model predicts flow stress with high accuracy, with relative errors remaining below one percent across the investigated loading conditions. In addition, the ANN implementation exhibits higher computational efficiency than the conventional constitutive model in explicit finite element simulations.It is concluded that the data-driven neural network approach can effectively replace traditional phenomenological constitutive models in finite element analysis. The proposed framework provides an efficient and reliable pathway for numerical modeling and simulation of metallic materials under complex thermo-mechanical conditions.

-

表 1 CoCrFeNiMn高熵合金的材料参数

Table 1. Material parameters of CoCrFeNiMn high-entropy alloy

E/GPa ν A/MPa B/MPa e1 n q c1 c2 210 0.3 596 99.9803 0.0162 1.1900 0.2350 8.5502 − 9.9978 e2 d1 d2 $ {\dot{\varepsilon }}_{0} $/s−1 T0/℃ Tm/℃ ρ/(kg·m−3) cp/(J·kg−1·K−1) 0.1073 2.8434 − 3.8275 0.02 20 1400 8020 490 表 2 训练阶段ANN的全局性能分析

Table 2. Global performance analysis of the ANN during the training phase

模型 N ERMS/Pa $ {\varDelta }(\sigma ) $/% $ {\varDelta }\left(\partial \sigma /\partial \varepsilon \right) $/% $ {\varDelta }\left(\partial \sigma /\partial \dot{\varepsilon }\right) $/% $ {\varDelta }\left(\partial \sigma /\partial T\right) $/% 3-16-1-tanh 78 9.79 0.048 1.977 0.792 0.556 3-16-1-sig 78 8.34 0.039 1.506 0.569 0.371 3-12-8-1-sig 95 7.02 0.030 1.168 0.521 0.408 3-12-8-1-tanh 95 3.86 0.026 0.519 0.380 0.355 3-12-18-1-sig 280 2.10 0.012 0.302 0.367 0.237 3-12-18-1-tanh 280 4.52 0.023 0.670 0.421 0.499 3-16-7-1-sig 182 5.04 0.041 1.132 0.496 0.517 3-16-7-1-sig 182 3.27 0.035 0.956 0.347 0.362 -

[1] 王强, 王建军, 张晓琼, 等. 金属热黏塑性本构关系的研究进展 [J]. 爆炸与冲击, 2022, 42(9): 091402. DOI: 10.11883/bzycj-2021-0443.WANG Q, WANG J J, ZHANG X Q, et al. Advances in the research of metallic thermo-viscoplastic constitutive relationships [J]. Explosion and Shock Waves, 2022, 42(9): 091402. DOI: 10.11883/bzycj-2021-0443. [2] BROWN C, MCCARTHY T, CHADHA K, et al. Constitutive modeling of the hot deformation behavior of CoCrFeMnNi high-entropy alloy [J]. Materials Science and Engineering: A, 2021, 826: 141940. DOI: 10.1016/j.msea.2021.141940. [3] LI Q, WU M X, YAN M R, et al. The influence of strain rates on the microstructural characteristics of CoCrFeNiMn high-entropy alloys during compression at elevated temperature [J]. Journal of Materials Science, 2025, 60(11): 5247–5266. DOI: 10.1007/s10853-025-10762-4. [4] LIN Y C, CHEN X M, LIU G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel [J]. Materials Science and Engineering: A, 2010, 527(26): 6980–6986. DOI: 10.1016/j.msea.2010.07.061. [5] ZHANG Y, ZUO T T, TANG Z, et al. Microstructures and properties of high-entropy alloys [J]. Progress in Materials Science, 2014, 61: 1–93. DOI: 10.1016/j.pmatsci.2013.10.001. [6] MENG B, WAN M, WU X D, et al. Constitutive modeling for high-temperature tensile deformation behavior of pure molybdenum considering strain effects [J]. International Journal of Refractory Metals and Hard Materials, 2014, 45: 41–47. DOI: 10.1016/j.ijrmhm.2014.03.005. [7] SHOGHI R, HARTMAIER A. A machine learning constitutive model for plasticity and strain hardening of polycrystalline metals based on data from micromechanical simulations [J]. Machine Learning: Science and Technology, 2024, 5(2): 025008. DOI: 10.1088/2632-2153/AD379E. [8] LU Z L, PAN Q L, LIU X Y, et al. Artificial neural network prediction to the hot compressive deformation behavior of Al-Cu-Mg-Ag heat-resistant aluminum alloy [J]. Mechanics Research Communications, 2011, 38(3): 192–197. DOI: 10.1016/j.mechrescom.2011.02.015. [9] HUANG X M, ZANG Y, GUAN B. Constitutive models and microstructure evolution of Ti-6Al-4V alloy during the hot compressive process [J]. Materials Research Express, 2021, 8(1): 016534. DOI: 10.1088/2053-1591/ABDAF0. [10] XU S C, YUAN L, SHAN D B. An artificial neural network constitutive model to predict high temperature flow behaviour in 18Ni(250) maraging steel [J]. Journal of Materials Research and Technology, 2025, 37: 157–172. DOI: 10.1016/J.JMRT.2025.06.002. [11] ALI U, MUHAMMAD W, BRAHME A, et al. Application of artificial neural networks in micromechanics for polycrystalline metals [J]. International Journal of Plasticity, 2019, 120: 205–219. DOI: 10.1016/j.ijplas.2019.05.001. [12] YASSAR S R, ABUOMAR O, HANSEN E, et al. On dislocation-based artificial neural network modeling of flow stress [J]. Materials & Design, 2010, 31(8): 3683–3689. DOI: 10.1016/j.matdes.2010.02.051. [13] 陈梓薇, 王仲琦, 曾令辉. 基于BP神经网络的爆炸用激波管峰值压力预测方法 [J]. 爆炸与冲击, 2024, 44(5): 054101. DOI: 10.11883/bzycj-2023-0187.CHEN Z W, WANG Z Q, ZENG L H. A method for predicting peak pressure in an explosion shock tube based on BP neural network [J]. Explosion and Shock Waves, 2024, 44(5): 054101. DOI: 10.11883/bzycj-2023-0187. [14] LENG Y, TAC V, CALVE S, et al. Predicting the mechanical properties of biopolymer gels using neural networks trained on discrete fiber network data [J]. Computer Methods in Applied Mechanics and Engineering, 2021, 387: 114160. DOI: 10.1016/J.CMA.2021.114160. [15] JAVADI A, REZANIA M. Intelligent finite element method: an evolutionary approach to constitutive modeling [J]. Advanced Engineering Informatics, 2009, 23(4): 442–451. DOI: 10.1016/j.aei.2009.06.008. [16] ASHTIANI R R, SHAHSAVARI P. A comparative study on the phenomenological and artificial neural network models to predict hot deformation behavior of AlCuMgPb alloy [J]. Journal of Alloys and Compounds, 2016, 687: 263–273. DOI: 10.1016/j.jallcom.2016.04.300. [17] 李秦超, 姚成宝, 程帅, 等. 神经网络状态方程在强爆炸冲击波数值模拟中的应用 [J]. 爆炸与冲击, 2023, 43(4): 044202. DOI: 10.11883/bzycj-2022-0222.LI Q C, YAO C B, CHENG S, et al. Application of the neural network equation of state in numerical simulation of intense blast wave [J]. Explosion and Shock Waves, 2023, 43(4): 044202. DOI: 10.11883/bzycj-2022-0222. [18] 何宇轩, 尹涛, 王曦. 有限元模型修正中的贝叶斯深度神经网络构架优化设计 [J]. 振动与冲击, 2025, 44(6): 184–190. DOI: 10.13465/j.cnki.jvs.2025.06.020.HE Y X, YIN T, WANG X. Architecture design of the Bayesian deep neural network in structural model updating [J]. Journal of Vibration and Shock, 2025, 44(6): 184–190. DOI: 10.13465/j.cnki.jvs.2025.06.020. [19] 敬霖, 冯超, 苏兴亚, 等. 高速动车组D2车轮钢的率温耦合变形机理与本构关系 [J]. 科学通报, 2022, 67(34): 4068–4079. DOI: 10.1360/TB-2022-0437.JING L, FENG C, SU X Y, et al. Strain rate-temperature coupling deformation mechanism and constitutive relationship of D2 wheel steel for high-speed EMUs [J]. Chinese Science Bulletin, 2022, 67(34): 4068–4079. DOI: 10.1360/TB-2022-0437. [20] ZHANG T, LU S H, WU Y X, et al. Optimization of deformation parameters of dynamic recrystallization for 7055 aluminum alloy by cellular automaton [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1327–1337. DOI: 10.1016/S1003-6326(17)60154-7. [21] DING R, GUO Z X. Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization [J]. Acta Materialia, 2001, 49(16): 3163–3175. DOI: 10.1016/S1359-6454(01)00233-6. [22] 王鸿立, 曾泽林, 苏兴亚, 等. 高铁接触网铜镁合金材料的率温耦合变形机理与本构参数 [J]. 爆炸与冲击, 2025, 45(12): 123101. DOI: 10.11883/bzycj-2025-0047.WANG H L, ZENG Z L, SU X Y, et al. Rate-temperature coupled deformation mechanism and constitutive parameters of catenary copper-magnesium alloy materials for high-speed railway [J]. Explosion and Shock Waves, 2025, 45(12): 123101. DOI: 10.11883/bzycj-2025-0047. [23] LIN Y C, LIU G. A new mathematical model for predicting flow stress of typical high-strength alloy steel at elevated high temperature [J]. Computational Materials Science, 2010, 48(1): 54–58. DOI: 10.1016/j.commatsci.2009.06.026. [24] SAMANTARAY D, MANDAL S, BHADURI A K. A comparative study on Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr-1Mo steel [J]. Computational Materials Science, 2009, 47(2): 568–576. DOI: 10.1016/j.commatsci.2009.09.025. [25] SAMANTARAY D, MANDAL S, BORAH U, et al. A thermo-viscoplastic constitutive model to predict elevated-temperature flow behaviour in a titanium-modified austenitic stainless steel [J]. Materials Science and Engineering: A, 2009, 526(1/2): 1–6. DOI: 10.1016/j.msea.2009.08.009. [26] ZHOU X Y, LIU Z A, YU C, et al. An artificial neural network-based data-driven constitutive model of shape memory alloys [J]. Acta Mechanica Sinica, 2025, 41(8): 424961. DOI: 10.1007/S10409-025-24961-X. [27] ROHR I, NAHME H, THOMA K, et al. Material characterisation and constitutive modelling of a tungsten-sintered alloy for a wide range of strain rates [J]. International Journal of Impact Engineering, 2008, 35(8): 811–819. DOI: 10.1016/j.ijimpeng.2007.12.006. [28] QIU J, CUI W L, JIN T, et al. A constitutive model coupled with distortional hardening for pressure-insensitive metals: focus on the Cantor alloy [J]. Journal of Materials Research and Technology, 2024, 28: 3735–3745. DOI: 10.1016/J.JMRT.2024.01.005. [29] WAKJIRA T G, ABUSHANAB A, ALAM M S. Hybrid machine learning model and predictive equations for compressive stress-strain constitutive modelling of confined ultra-high-performance concrete (UHPC) with normal-strength steel and high-strength steel spirals [J]. Engineering Structures, 2024, 304: 117633. DOI: 10.1016/J.ENGSTRUCT.2024.117633. [30] MING L, PANTALÉ O. An efficient and robust VUMAT implementation of elastoplastic constitutive laws in Abaqus/Explicit finite element code [J]. Mechanics and Industry, 2018, 19(3): 308. DOI: 10.1051/meca/2018021. [31] ABADI M, BARHAM P, CHEN J M, et al. TensorFlow: a system for large-scale machine learning [C]//Proceedings of the 12th USENIX Symposium on Operating Systems Design and Implementation. Savannah: USENIX Association, 2016: 265–283. [32] KINGMA D P, BA J. Adam: a method for stochastic optimization [C]//Proceedings of the 3rd International Conference on Learning Representations (ICLR). San Diego: ICLR, 2015. [33] SIMO C J, HUGHES T J R. Computational inelasticity [M]. New York: Springer, 1998. DOI: 10.1007/B98904. [34] PANTALÉ O, TIZE MHA P, TONGNE A. Efficient implementation of non-linear flow law using neural network into the Abaqus Explicit FEM code [J]. Finite Elements in Analysis and Design, 2022, 198: 103647. DOI: 10.1016/J.FINEL.2021.103647. [35] STEPANOV N D, SHAYSULTANOV D G, YURCHENKO N Y, et al. High temperature deformation behavior and dynamic recrystallization in CoCrFeNiMn high entropy alloy [J]. Materials Science and Engineering: A, 2015, 636: 188–195. DOI: 10.1016/j.msea.2015.03.097. [36] CHEN H Y, LIU Y, WANG Y G, et al. Temperature-dependent dynamic compressive properties and failure mechanisms of the additively manufactured CoCrFeMnNi high entropy alloy [J]. Materials and Design, 2022, 224: 111324. DOI: 10.1016/J.MATDES.2022.111324. -

下载:

下载: