Ductile-brittle transition behaviors of nodular cast iron under low temperature and impact loading

-

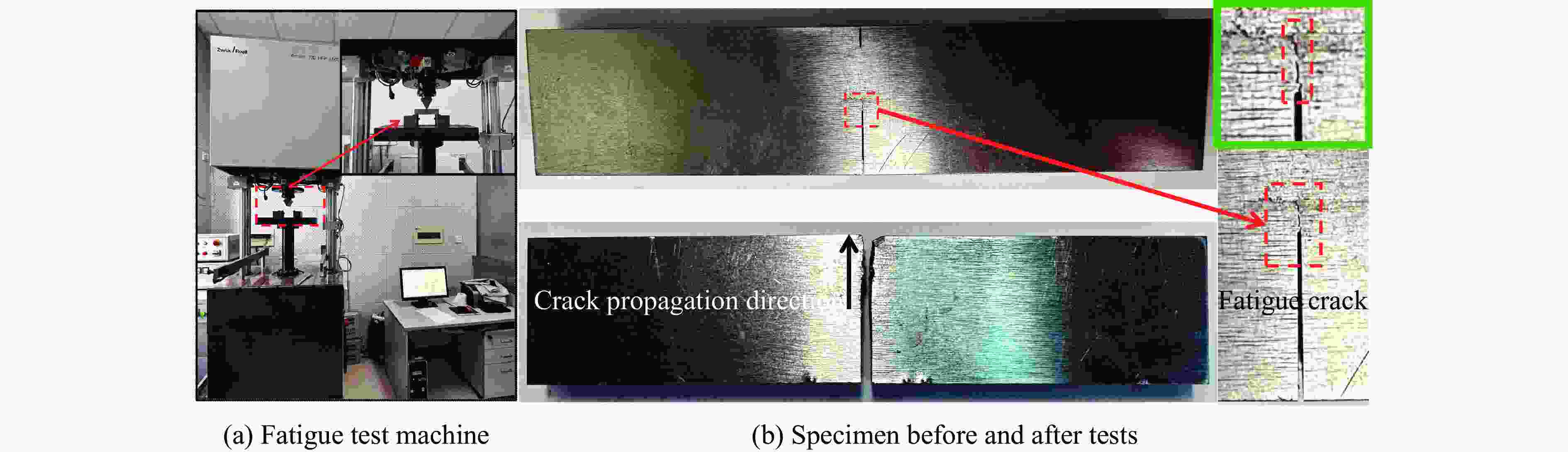

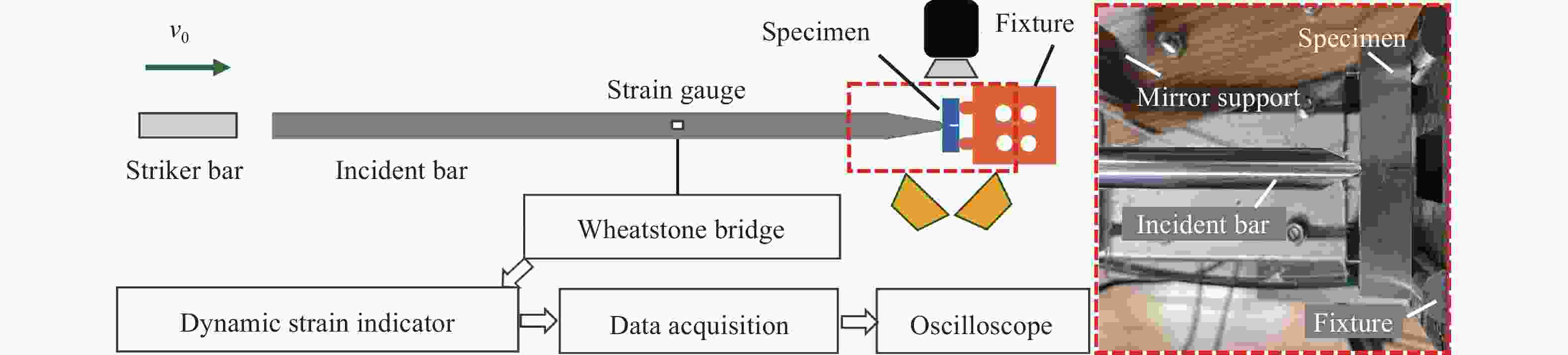

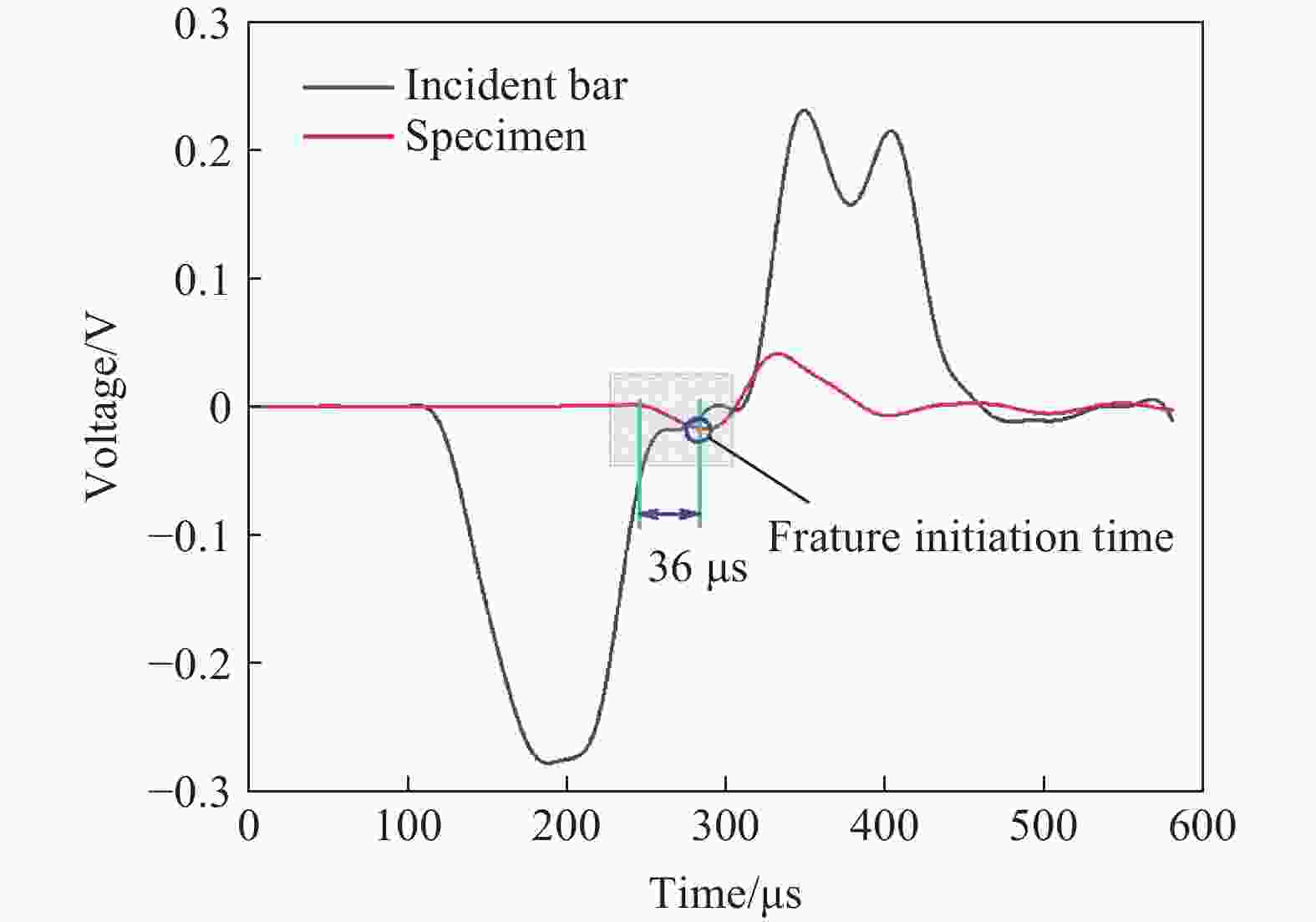

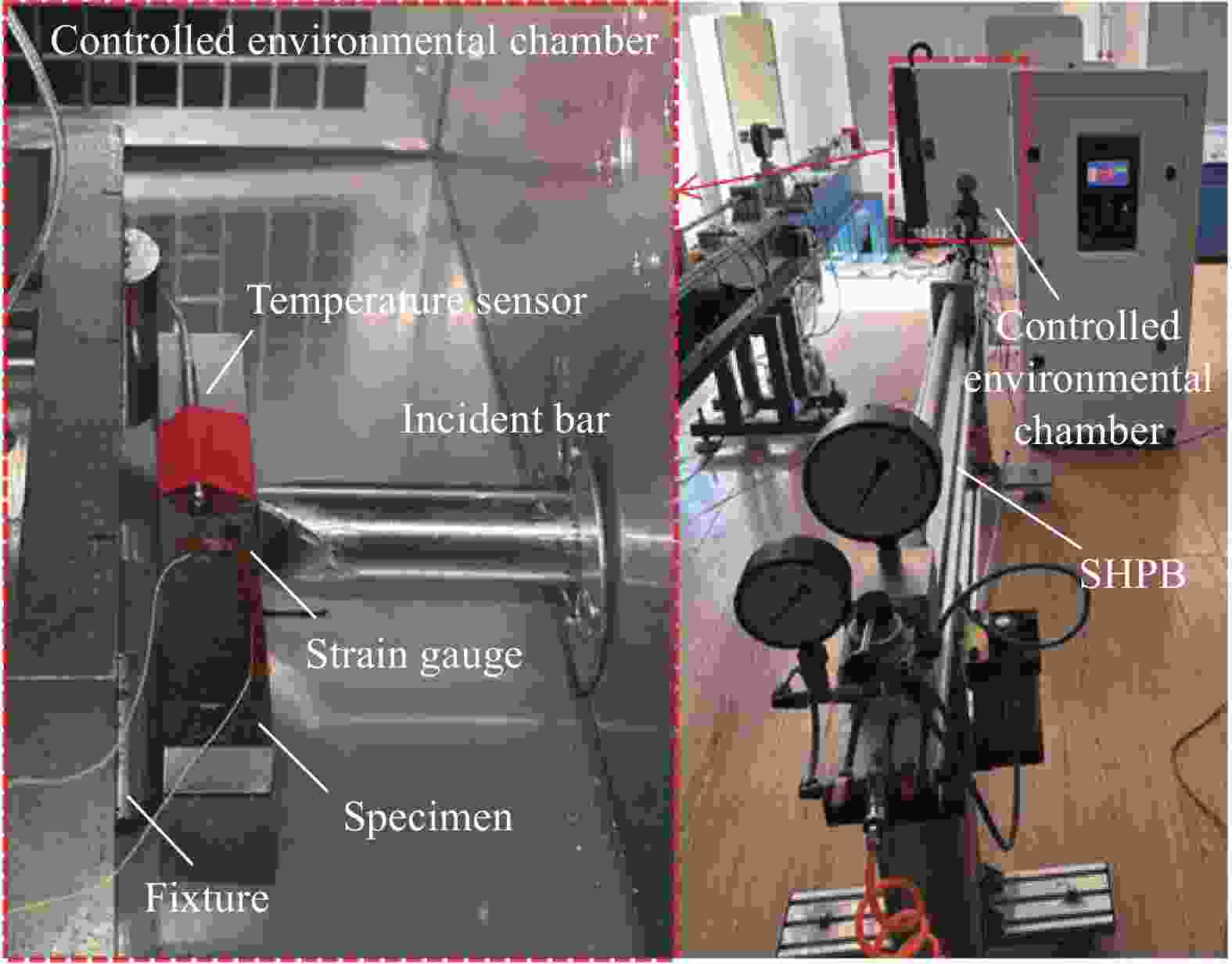

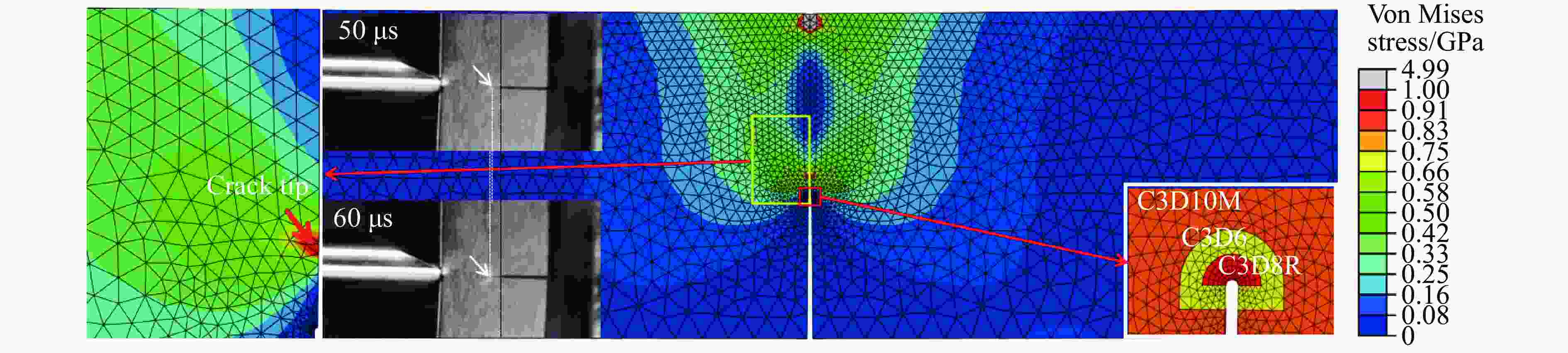

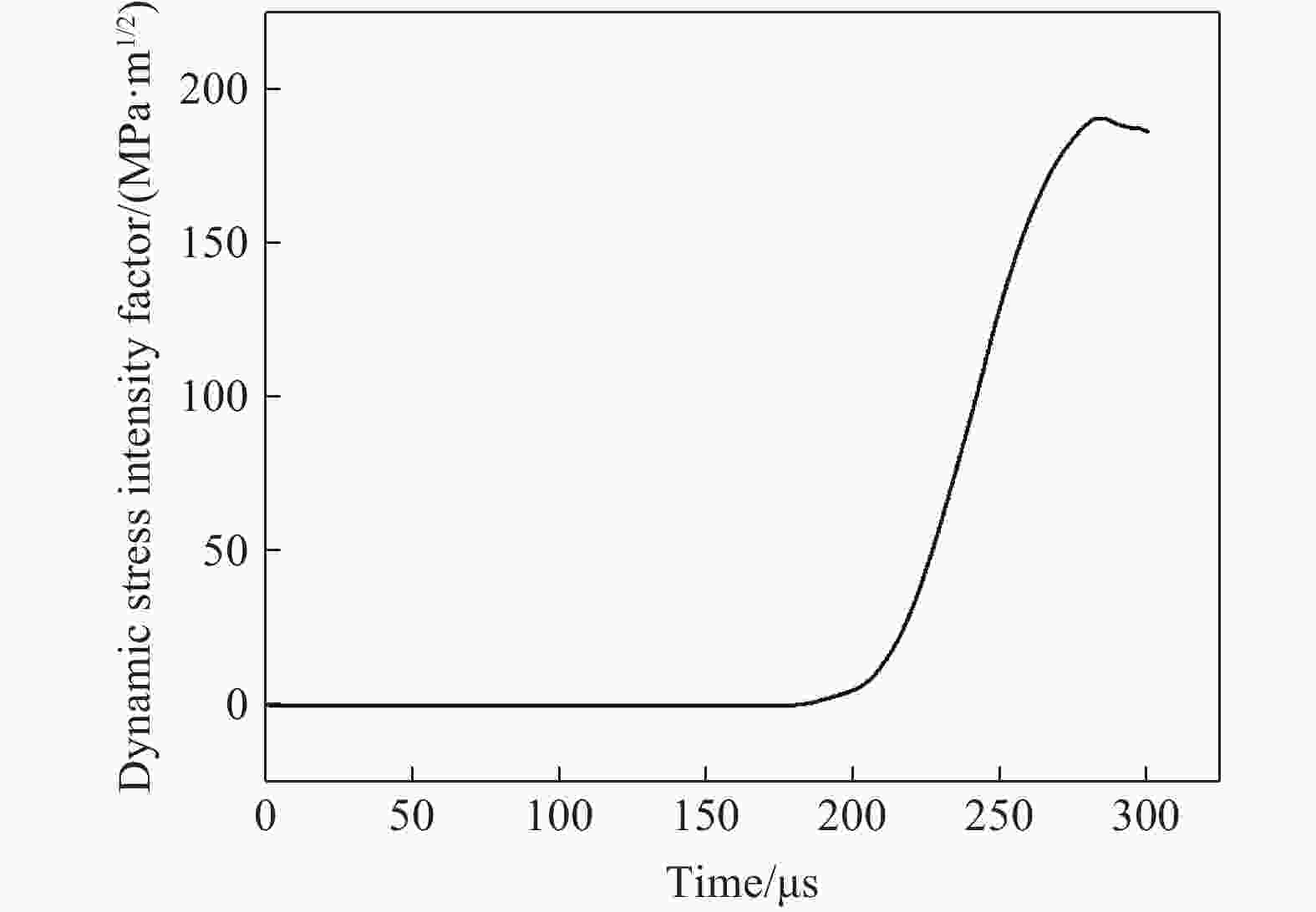

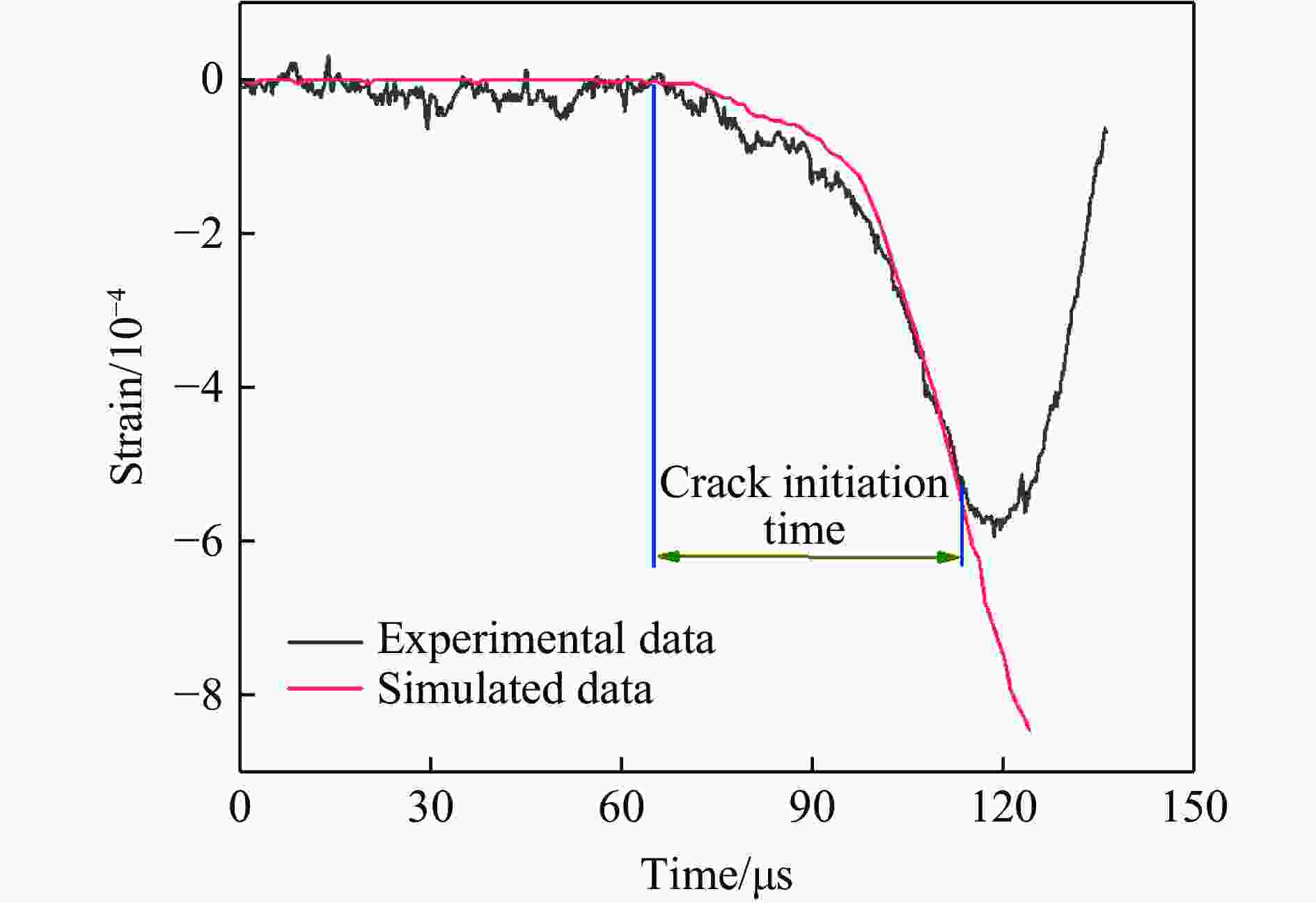

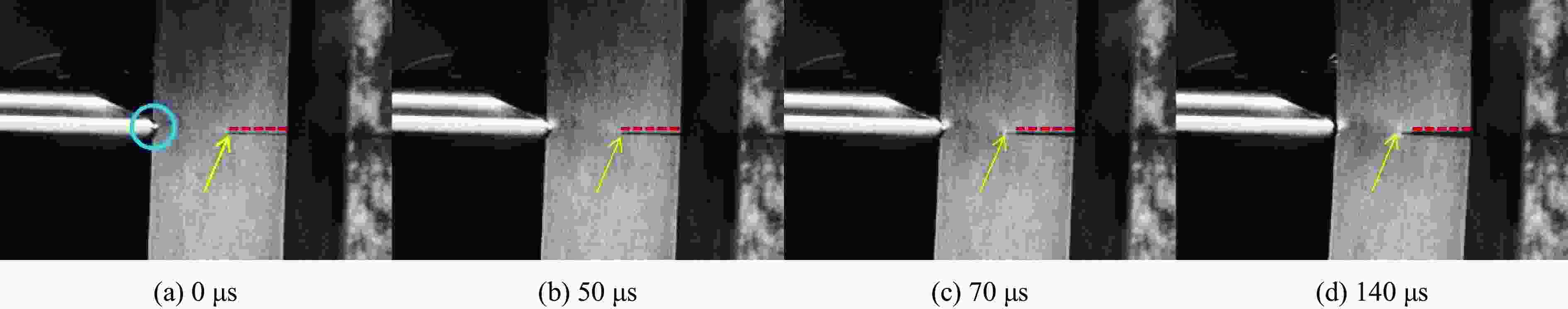

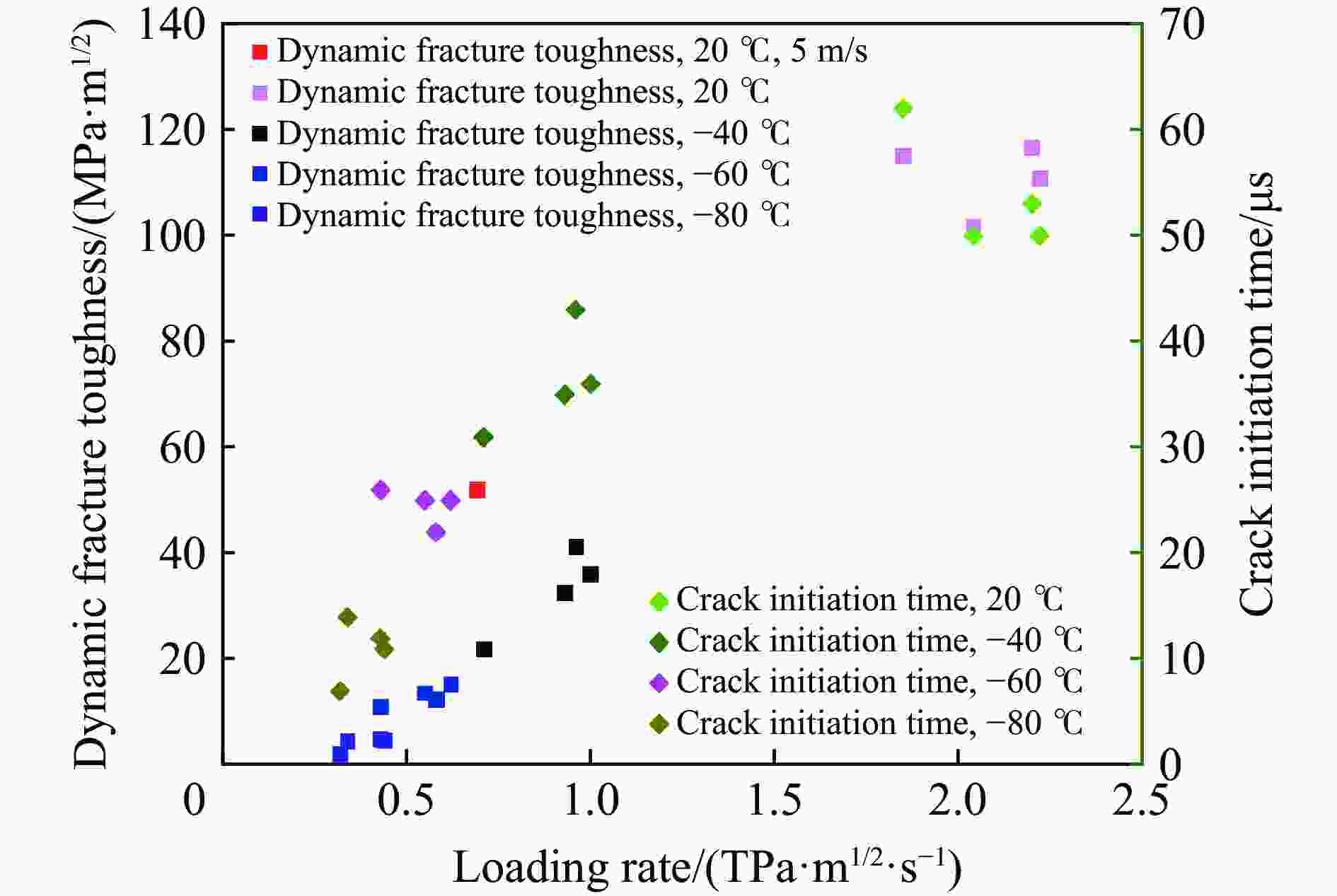

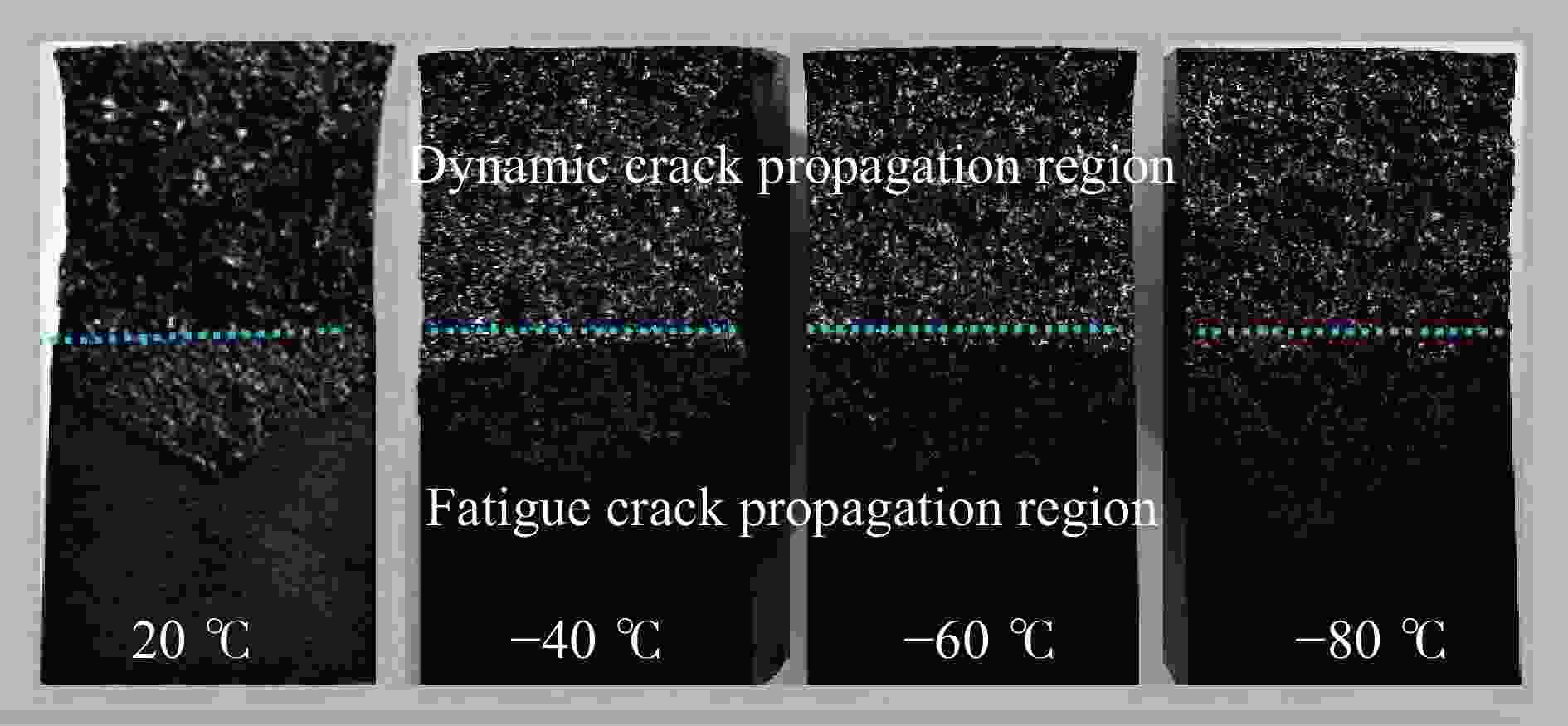

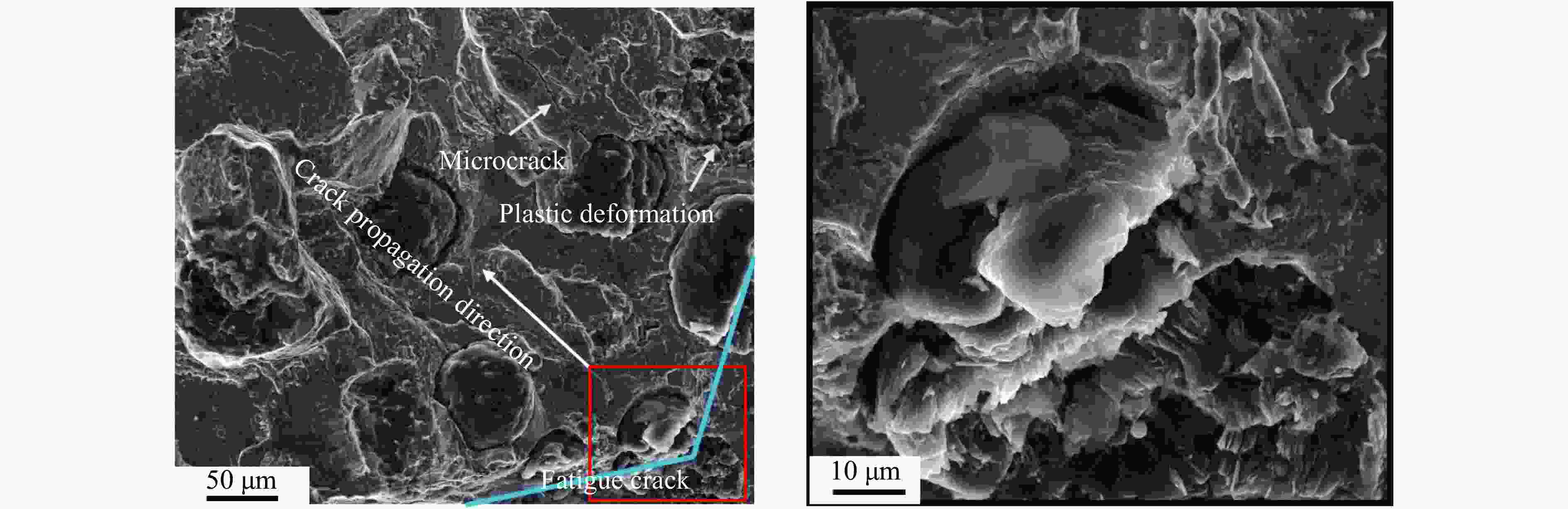

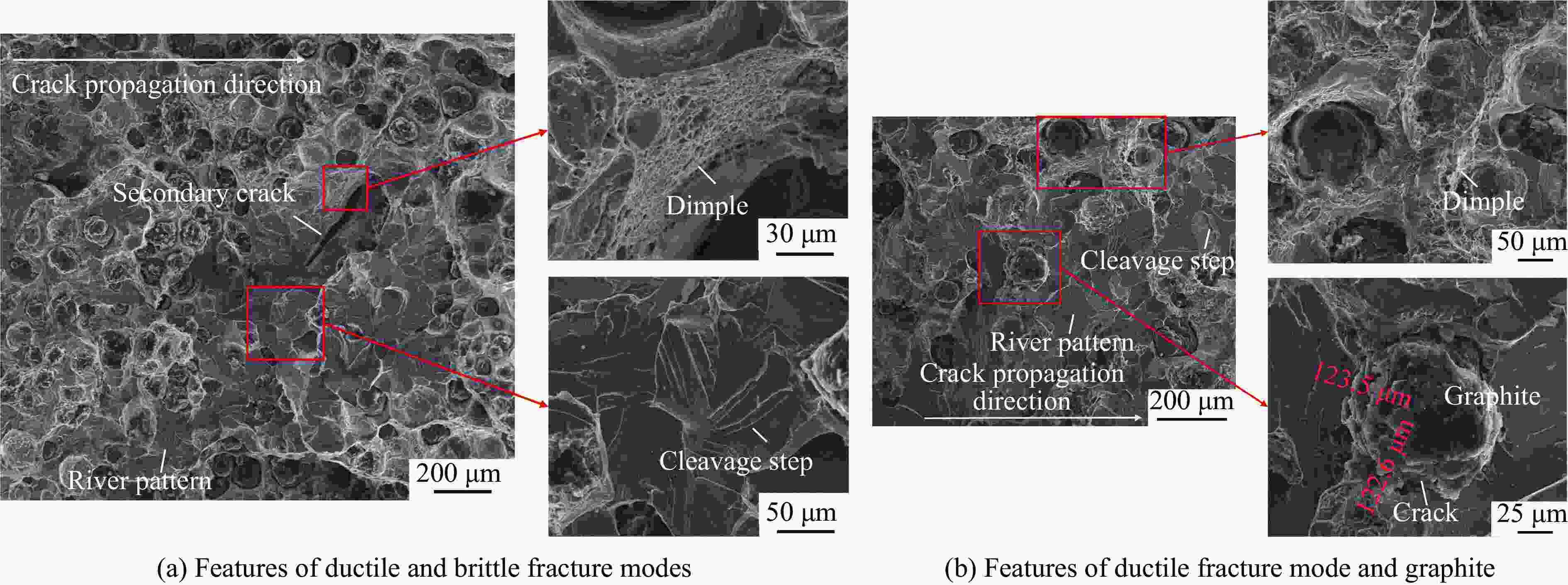

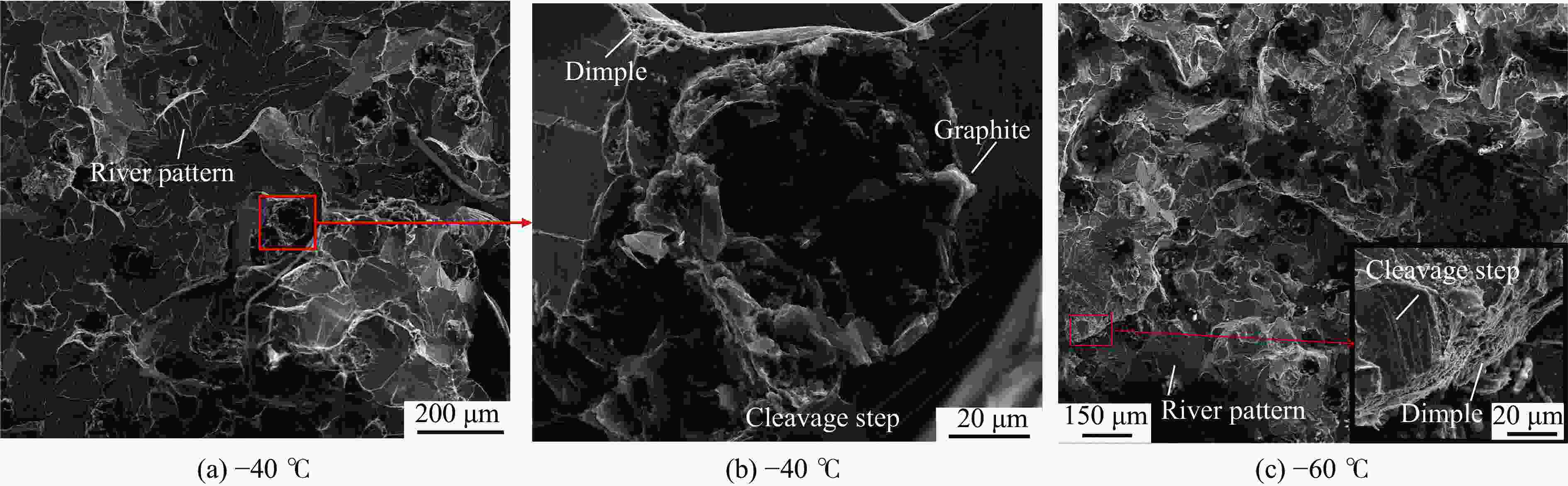

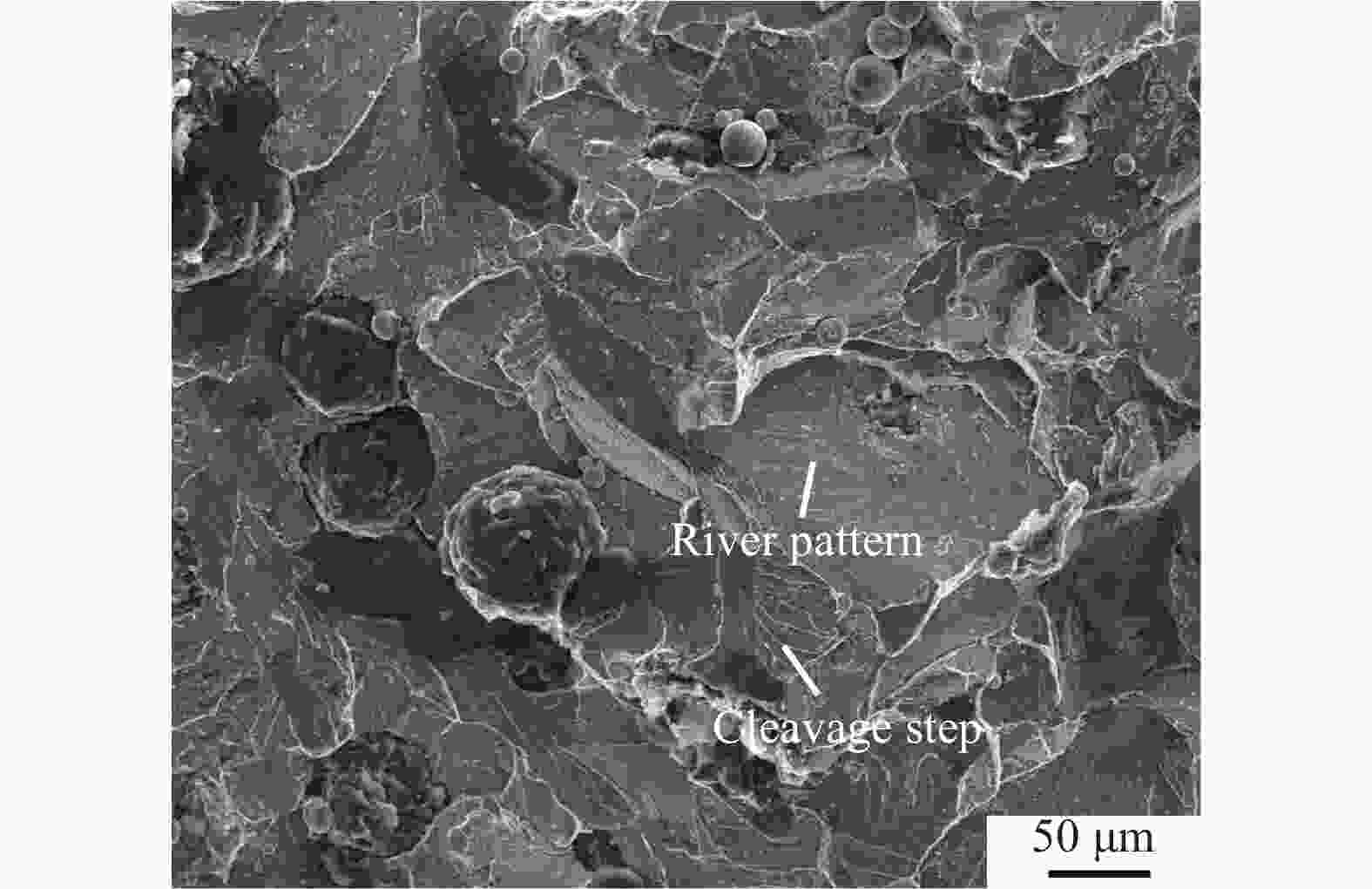

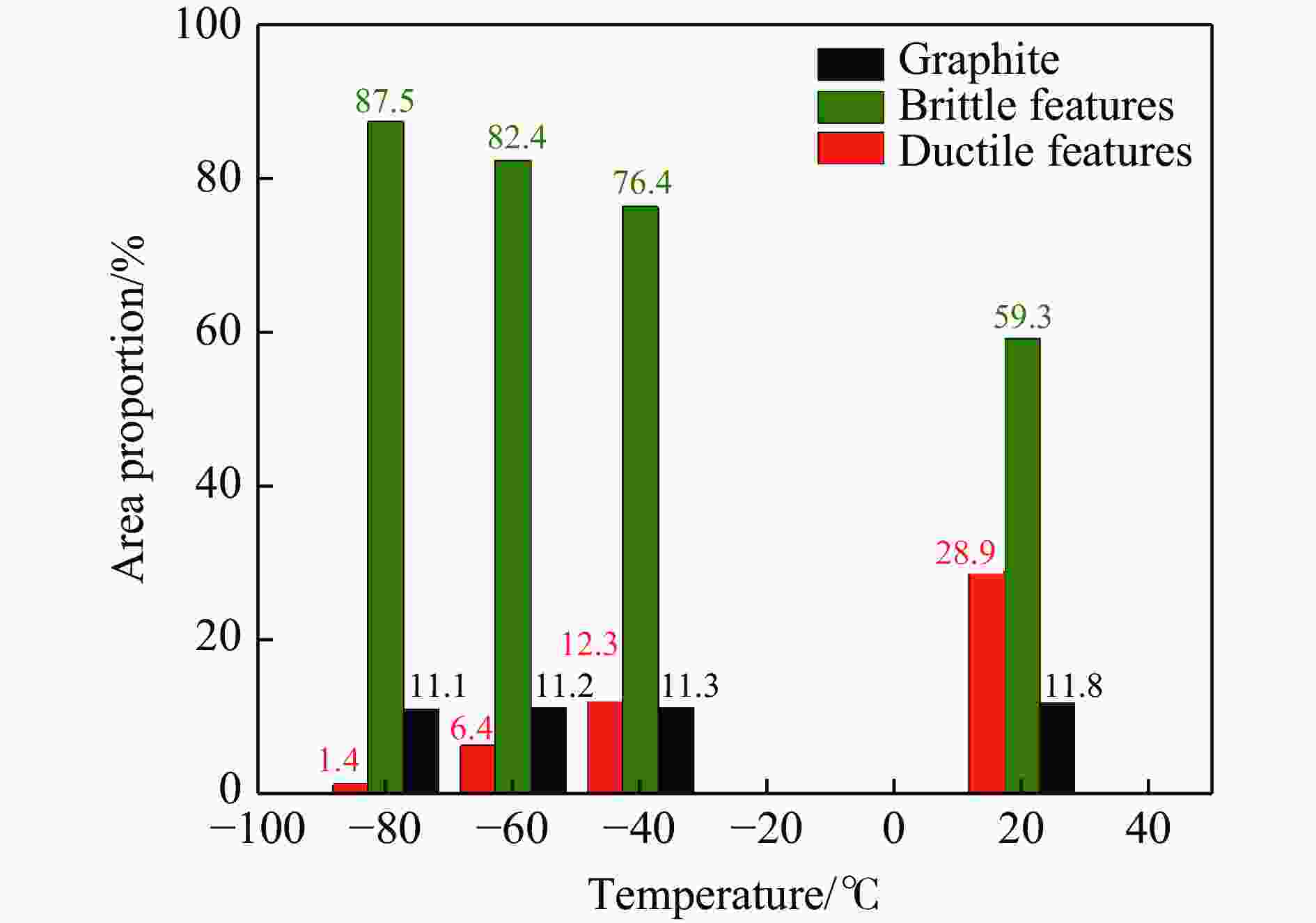

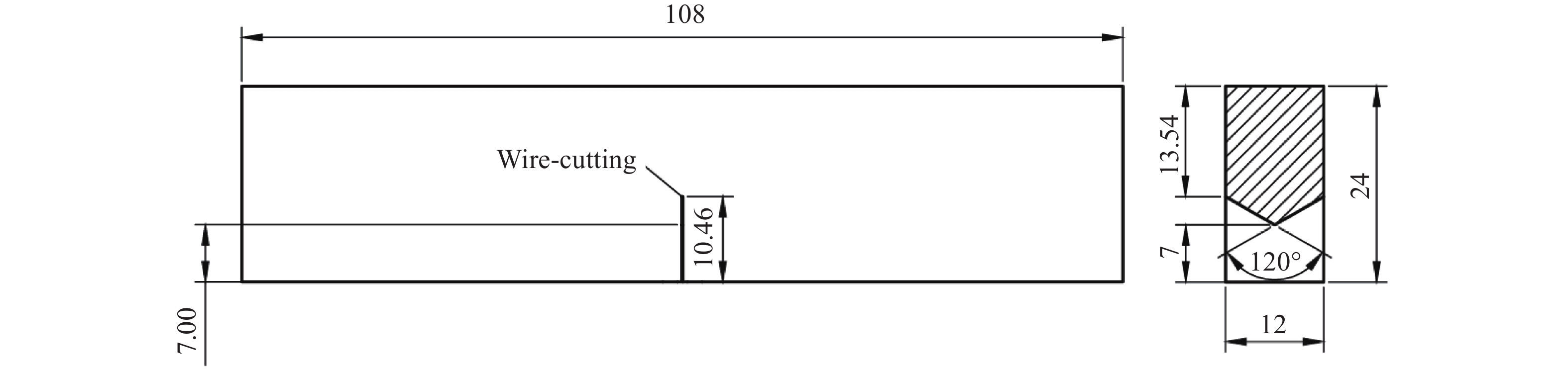

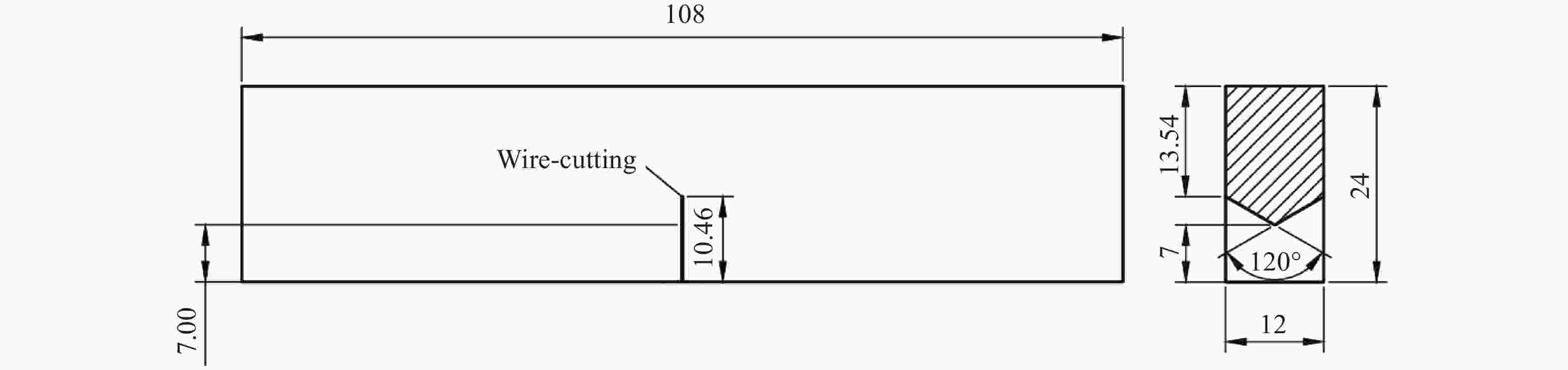

摘要: 为了解核乏燃料储运容器等球墨铸铁结构在低温、冲击环境下的动态断裂特性,通过改进的分离式霍普金森压杆技术对球墨铸铁材料在不同温度(20、−40、−60和−80 ℃)下的Ⅰ型动态断裂韧性进行了测试,并着重研究了材料的韧脆转变行为。试样的起裂时间由应变法确定,采用实验-数值方法确定了裂尖动态应力强度因子和材料的Ⅰ型动态断裂韧性。结果表明,在相同冲击速度加载下,球墨铸铁的Ⅰ型动态断裂韧性随温度的降低而明显降低,起裂时间也随温度降低而缩短。通过对断口进行微观分析,发现在不同温度下材料存在失效机理的转变。随着温度的降低,断口韧窝减少,河流花样以及解理台阶增多。通过对韧性与脆性微观形貌特征进行量化统计,发现材料在低温下存在延性特征变弱、脆性增强的规律,这种韧脆转变现象与材料断裂韧性的测试结果相吻合。Abstract: To understand the dynamic fracture characteristics of nodular cast iron structures such as the spent nuclear fuel storage and transportation vessels under low temperatures and dynamic loads, the mode I dynamic fracture toughness (DFT) of nodular cast iron was tested at different temperatures (20, −40, −60 and −80 ℃) using an improved split Hopkinson pressure bar technique, and focused on studying the ductile-brittle transition behavior of the material. Standard three-point bending specimens with a fatigue crack were pre-fabricated before the experiment. A special fixture was used to replace the transmitter bar, while the temperature was controlled by a specially designed environmental chamber. The crack initiation time of the specimen was determined by the strain gauge method, and the dynamic stress intensity factor (DSIF) at the crack tip was determined using the experimental-numerical method. Mesh refinement and element transition were used at the crack tip region to ensure a high-accuracy result of the displacement field. On this basis, the mode Ⅰ DFT of the material was finally determined. The results show that under the same impact velocity, the DFT and the fracture initiation time of nodular cast iron decrease significantly with the decrease in temperature. As the temperature decreases, the macroscopic fracture surface of nodular cast iron changes from rough to relatively flat, indicating a change in the failure modes of the material. The effect of temperature on the failure mode is further verified by quantitative microscopic analysis of fracture surfaces. As the temperature decreases, the number of dimples on the fracture surface decreases, while river patterns and cleavage steps increase. It means that the ductility of the material is weakened, but the brittleness is enhanced at low temperatures. This ductile-brittle transition phenomenon is consistent with the tendency of the measured toughness of the material.

-

表 1 不同材料的力学性能参数

Table 1. Mechanical properties of materials

部件 材料 ρ/(kg·m−3) E/GPa μ 入射杆 60Si2Mn 7850 210 0.3 试样 球墨铸铁 7300 164 0.3 夹具 40Cr 7820 199 0.3 表 2 常温下球墨铸铁的动态断裂参数

Table 2. Dynamic fracture parameters of nodular cast iron at room temperature

温度/℃ 加载速率/

(TPa·m1/2·s−1)起裂时刻/μs 起裂时刻

区间/μs动态断裂韧性/

(MPa·m1/2)20 2.20 53 [50,70] 116.6 20 2.22 50 [50,70] 110.9 20 1.85 62 [50,70] 115.0 20 2.04 50 [50,60] 101.8 表 3 低温下球墨铸铁的动态断裂参数

Table 3. Dynamic fracture parameters of nodular cast iron at low temperatures

温度/℃ 加载速率/(TPa·m1/2·s−1) 起裂时间/μs 动态断裂韧性/(MPa·m1/2) 动态断裂韧性平均值/(MPa·m1/2) −40 1.00 36 36.10 33.00 0.93 35 32.60 0.96 43 41.40 0.71 31 22.00 −60 0.55 25 13.71 13.3 0.43 26 11.12 0.58 22 12.85 0.62 25 15.38 −80 0.34 14 4.70 4.2 0.32 7 2.27 0.44 11 4.86 0.43 12 5.10 -

[1] 张海红, 胡晓明, 程久欢. LNG低温管道材料研究 [J]. 化工科技市场, 2010, 33(2): 32–41. DOI: 10.3969/j.issn.1009-0797.2010.01.057.ZHANG H H, HU X M, CHENG J H. Research on LNG cryogenic pipeline materials [J]. Chemical Technology Market, 2010, 33(2): 32–41. DOI: 10.3969/j.issn.1009-0797.2010.01.057. [2] 马敬仲, 丁建中, 尤其光, 等. 超低温高韧性球墨铸铁QT400-18AL的研究及应用 [J]. 铸造, 2012, 61(8): 856–861. DOI: 10.3969/j.issn.1001-4977.2012.08.002.MA J Z, DING J Z, YOU Q G, et al. Study and application of ultra-low temperature and high toughness ductile ductile iron QT400-18AL [J]. Foundry Journal Agency, 2012, 61(8): 856–861. DOI: 10.3969/j.issn.1001-4977.2012.08.002. [3] 叶忠志, 张园星. 液化天然气BOG压缩机选型分析 [J]. 石油和化工设备, 2013, 16(3): 61–64. DOI: 10.3969/j.issn.1674-8980.2013.03.021.YE Z Z, ZHANG Y X. Selection analysis of liquefied natural gas BOG compressor [J]. Petroleum and Chemical Equipment, 2013, 16(3): 61–64. DOI: 10.3969/j.issn.1674-8980.2013.03.021. [4] 阳东升, 费珂, 何旭东, 等. 低温低应力工况下管道材料的应用 [J]. 化工设计, 2019, 29(3): 29–31, 50.YANG D S, FEI K, HE X D, et al. Application of pipeline materials under low temperature and low stress condition [J]. Chemical Engineering Design, 2019, 29(3): 29–31, 50. [5] 张宇航, 郭兴春, 付彬国, 等. 铁素体球墨铸铁低温冲击韧性 [J]. 科学技术与工程, 2022, 22(17): 6937–6941.ZHANG Y H, GUO X C, FU B G, et al. Low temperature impact toughness of ferritic ductile iron [J]. Science Technology and Engineering, 2022, 22(17): 6937–6941. [6] 朱华明, 辛国忠, 胡苟生, 等. 铸态低温高韧性球墨铸铁QT400-18L缸体的研究及应用 [J]. 铸造技术, 2014, 35(1): 106–108.ZHU H M, XIN G Z, HU G S, et al. Research and application of QT400-18L cylinder block of cast ductile iron with low temperature and high toughness [J]. Foundry Technology, 2014, 35(1): 106–108. [7] 郭大展, 胡志忠, 胡明初. 球墨铸铁冲击断裂特性研究 [J]. 现代铸铁, 1984(1): 4–7.GUO D Z, HU Z Z, HU M C. Study on impact fracture characteristics of ductile iron [J]. Modern Cast Iron, 1984(1): 4–7. [8] 王强, 李雷, 桃野正. 球墨铸铁低温冲击韧性的研究 [J]. 铸造, 2010, 59(2): 193–196.WANG Q, LI L, TAO Y Z. Study on low temperature impact toughness of ductile iron [J]. Foundry, 2010, 59(2): 193–196. [9] BAER W, WOSSIDLO P, ABBASI B, et al. Large scale testing and statistical analysis of dynamic fracture toughness of ductile cast iron [J]. Engineering Fracture Mechanics, 2009, 76(8): 1024–1036. DOI: 10.1016/j.engfracmech.2009.01.005. [10] KOBAYASHI T, YAMADA S. Evaluation of static and dynamic fracture toughness in ductile cast iron [J]. Metallurgical and Materials Transactions A, 1994, 25(11): 2427–2736. DOI: 10.1016/0013-7944(88)90197-X. [11] CARPENTER S H, ZHU Z. Correlation of the acoustic emission and the fracture toughness of ductile nodular cast iron [J]. Journal of Materials Science, 1991, 26(8): 2057–2062. DOI: 10.1007/BF00549167. [12] 小林俊郎, 陶勇. 等温淬火低合金球墨铸铁断裂韧性的评价 [J]. 国外机车车辆工艺, 1988(4): 16–22XIAO L J L, TAO Y. Evaluation of fracture toughness of isothermal quenching low alloy ductile iron [J]. Foreign Rolling Stock Technology, 1988(4): 16–22. [13] FAN C, XU Z, HAN Y, et al. Study on mode I dynamic fracture characteristics with a mini three-point bending specimen for the split Hopkinson bar technique [J]. International Journal of Impact Engineering, 2023: 104635. DOI: 10.1016/j.ijimpeng.2023.104635. [14] 范昌增, 许泽建, 何晓东, 等. 加载速率对40Cr钢Ⅱ型动态断裂特性的影响 [J]. 爆炸与冲击, 2021, 41(8): 083101. DOI: 10.11883/bzycj-2021-0029.FAN C Z, XU Z J, HE X D, et al. Effect of loading rate on the modeⅡ dynamic fracture characteristics of 40Cr steel [J]. Explosion and Shock Waves, 2021, 41(8): 083101. DOI: 10.11883/bzycj-2021-0029. [15] 王自强, 陈少华. 高等断裂力学 [M]. 北京: 科学出版社, 2009: 24–26. [16] STANDARD A. 1990 annual book of ASTM standards: E399-90 [R]. Philadelphia: American Society for Testing and Materials, 2002: 13–15. [17] PANDOURIA A K, TIWARI V. Investigations into the static and dynamic fracture initiation and propagation toughness of AA2014-T6 incorporating temperatures effects [J]. Engineering Fracture Mechanics, 2023, 281: 109136. DOI: 10.1016/j.engfracmech.2023.109136. [18] 高民强. V法铸造制备高强度高韧性球墨铸铁缸套的研究 [D]. 沈阳: 沈阳工业大学, 2016: 22–29. [19] 国家市场监督管理总局和国家标准化管理委员会. 球墨铸铁金相检验:GB/T 9441—2021 [S]. 北京: 中国标准出版社, 2021. [20] LEE S C, HSU C H, FENG H P, et al. Influence of casting size and graphite nodule refinement on fracture toughness of austempered ductile iron [J]. Metallurgical and Materials Transactions A, 1998, 29(10): 2511–2521. DOI: 10.1007/s11661-998-0223-x. [21] MOTTITSCHKA T, PUSCH G, BIERMANN H, et al. Influence of graphite spherical size on fatigue behaviour and fracture toughness of ductile cast iron EN-GJS-400-18LT [J]. Journal of Physics Conference, 2012, 103(1): 87–96. DOI: 10.3139/146.110636. [22] NILSSON K F, BLAGOEVA D, MORETTO P. An experimental and numerical analysis to correlate variation in ductility to defects and microstructure in ductile cast iron components [J]. Engineering Fracture Mechanics, 2006, 73(9): 1133–57. DOI: 10.1016/j.engfracmech.2005.12.005. -

下载:

下载: