Comparative study of simulation and experiment on shielding performance of shield with separated rear wall

-

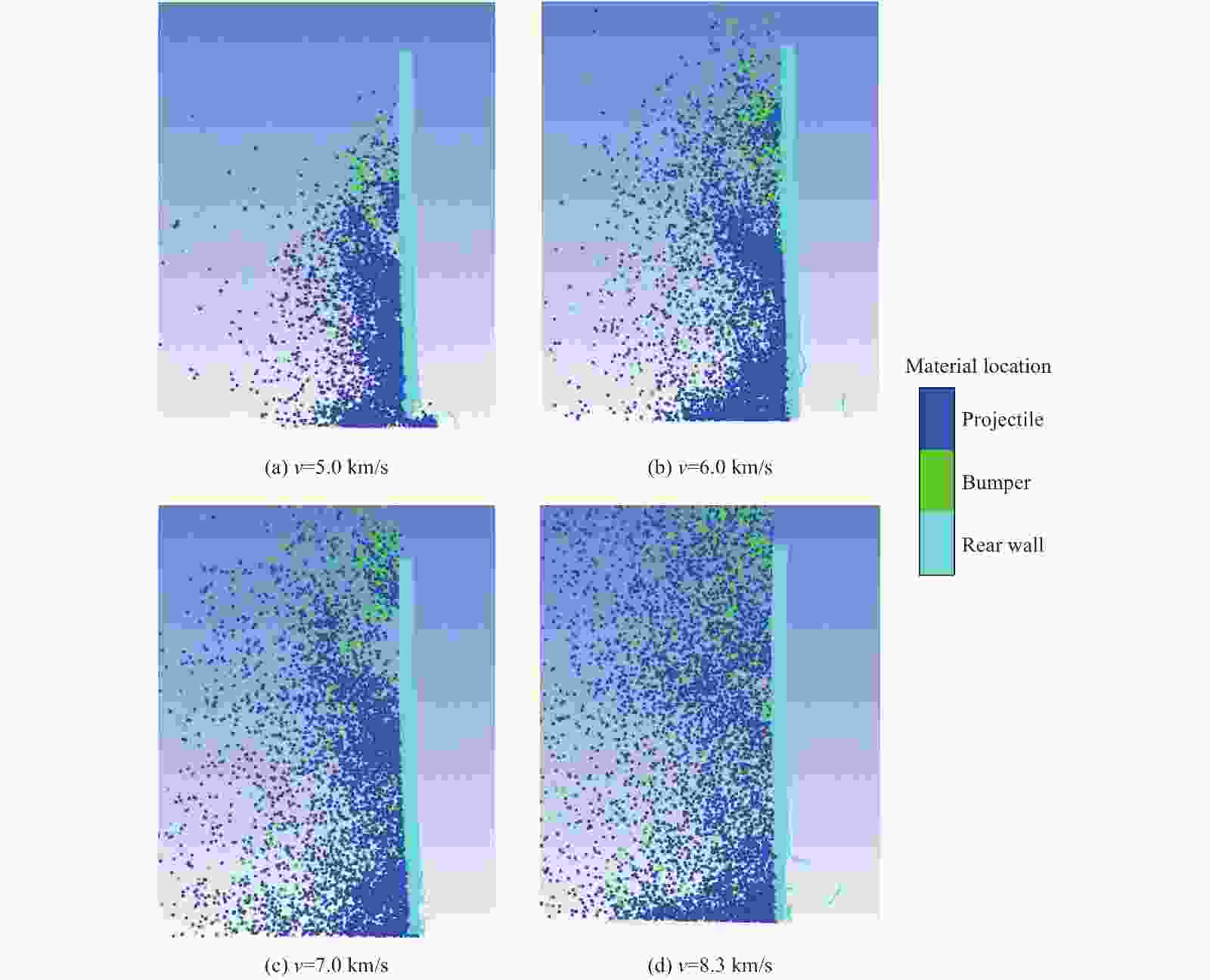

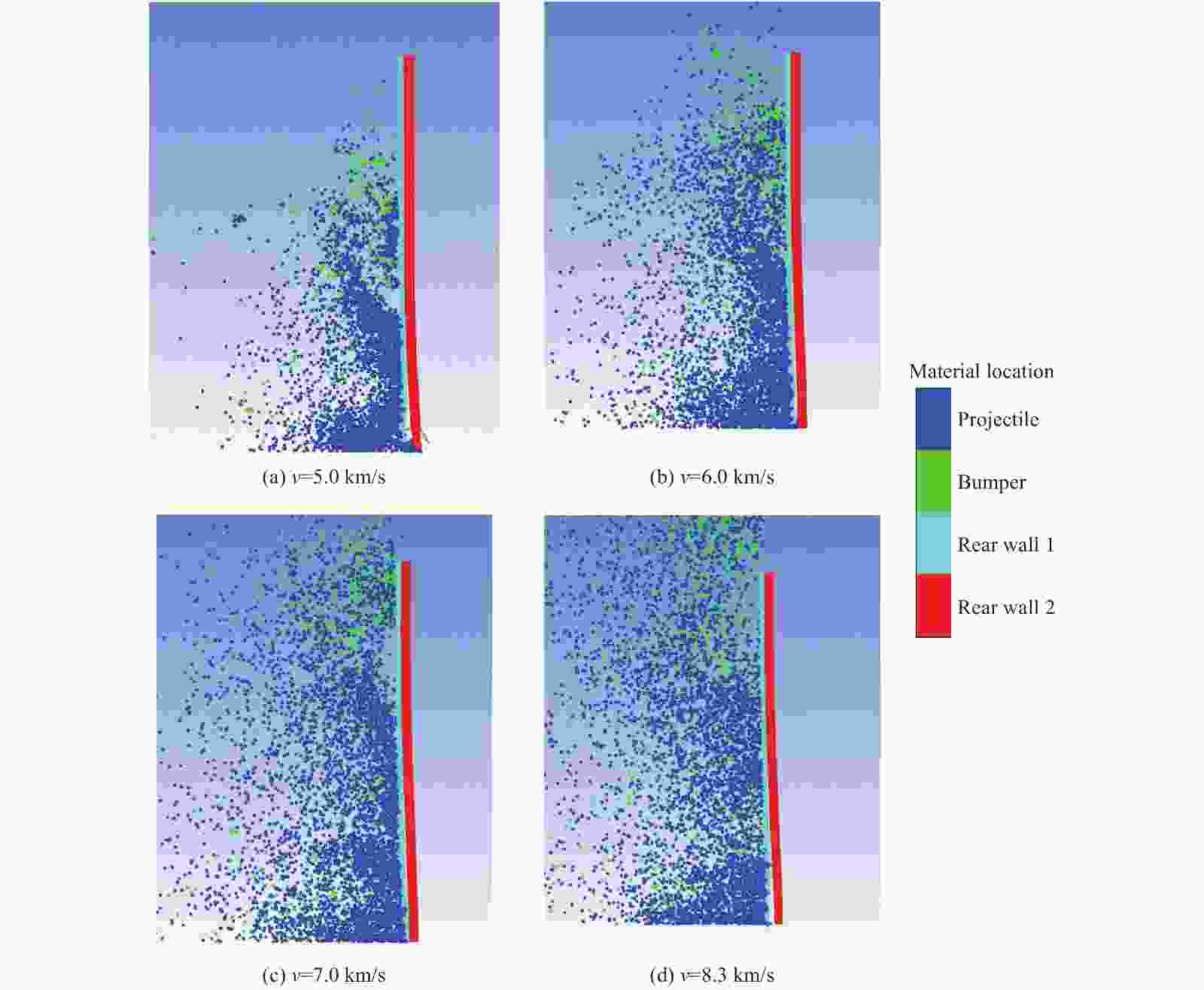

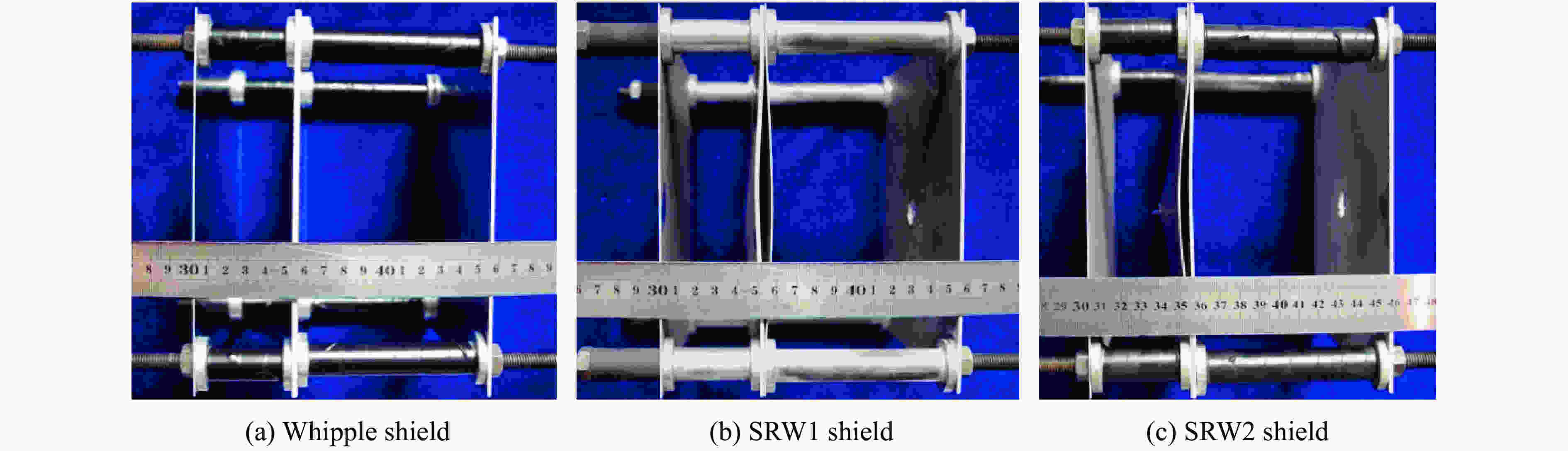

摘要: 为验证利用后墙拆分方式提升防护结构性能的可行性,通过开展数值模拟(铝弹丸直径6.0 mm,撞击速度5.0~8.3 km/s)和超高速撞击实验(铝弹丸直径6.0 mm,撞击速度约8.3 km/s),研究了3种防护结构的性能差异以及不同撞击速度对结构防护性能的影响。防护结构主要包括Whipple结构和两种后墙拆分结构。针对直径6.0 mm铝弹丸分别以5.0、6.0、7.0、8.3 km/s的速度撞击防护结构的工况,借助Autodyn软件开展了数值模拟,并将模拟结果与在弹道靶设备上获得的超高速撞击实验结果进行了对比。模拟结果与实验结果均表明,在相同撞击状态下两种后墙拆分结构的防护性能有所差异,但均优于相同面密度的Whipple结构,且随着撞击速度的提高,这种优势具有增大的趋势。

-

关键词:

- 空间碎片 /

- Whipple防护结构 /

- 超高速撞击 /

- 后墙

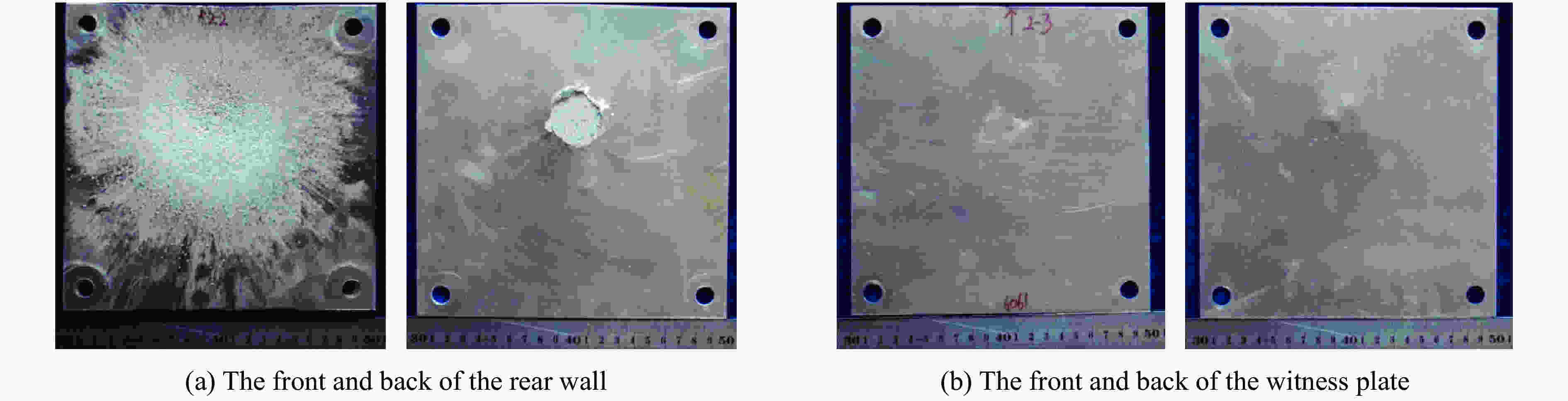

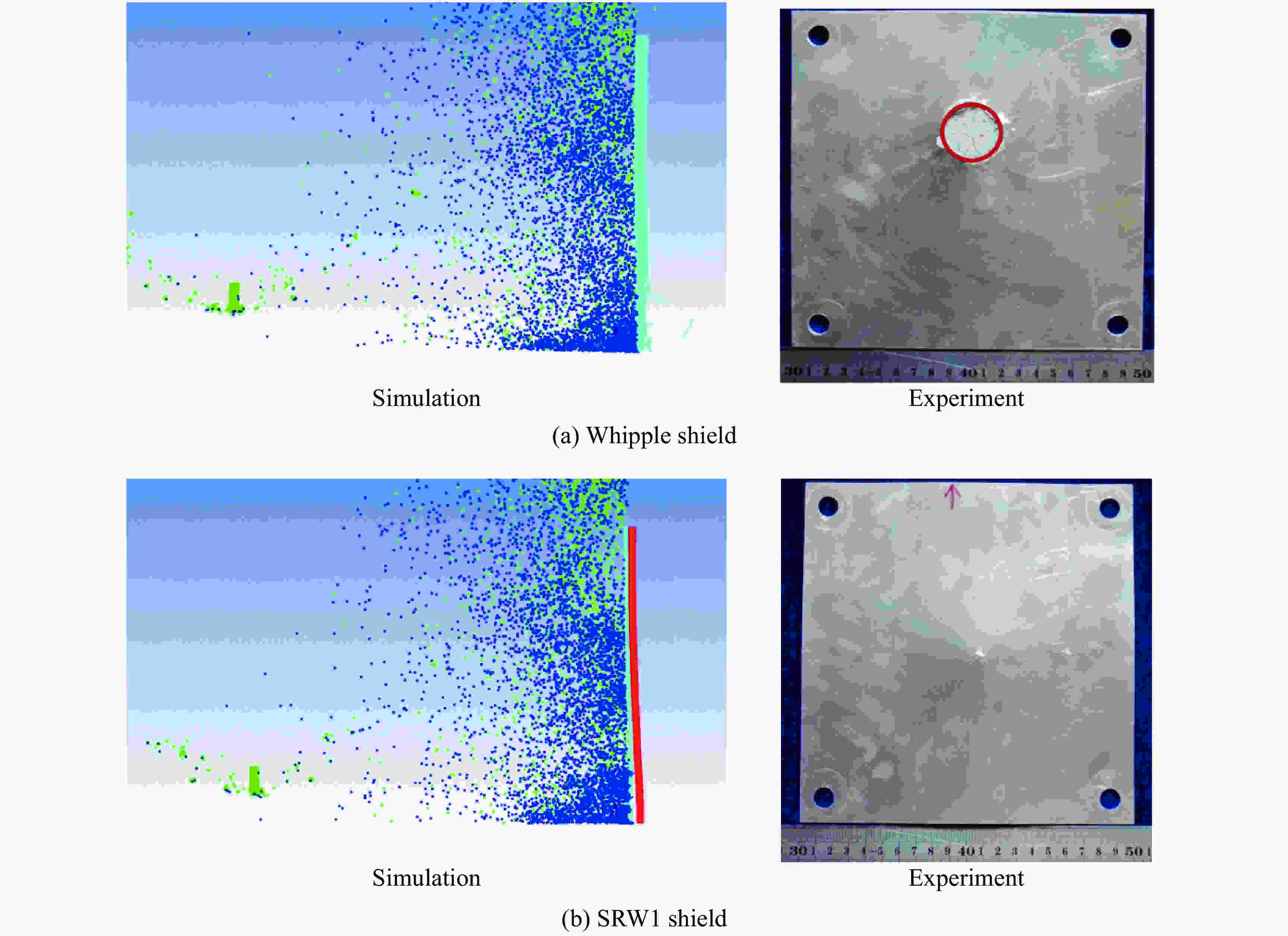

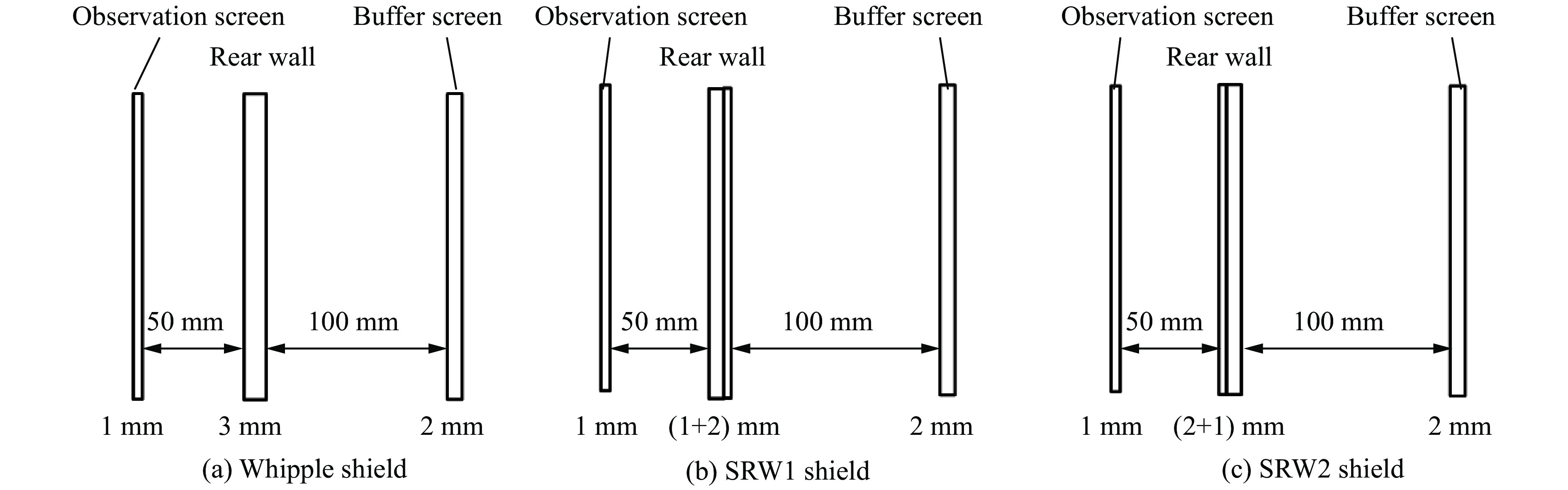

Abstract: In order to study the feasibility and effectiveness of the shield with separated rear wall (SRW), both the hypervelocity experiments and simulations were performed to investigate the performances of shields with different separated rear walls. The effect of impact velocity on the shielding performance was also studied. Three kinds of shields were designed, including a Whipple shield and two kinds of SRW shields. The AUTODYN software was based on to numerically simulate the penetration of 6.0-mm-diameter aluminum projectiles with the initial impact velocities of 5.0, 6.0, 7.0 and 8.3 km/s, respectively, into the shields. By comparing the damages in the backs of the rear walls among the three kinds of shields, the preliminary conclusion was drawn that the performances of the SRW shields were better than that of the Whipple shield. And the higher the impact velocity, the more obvious the advantage of the SRW shields. The tests were carried out in the hypervelocity ballistic range of China Aerodynamics Research and Development Center. The diameter of an aluminum projectile is 6.0 mm, and the impact velocity is about 8.3 km/s. The perforation and spall characteristics of the rear walls in the tests are consistent with the simulated results. The experiments not only prove the effectiveness of the simulation method, but also prove that the SRW shields have better protecting performances. Compared with the complete aluminum plate, a new free interface is added inside the structures of the SRW shields, which will reflect the shock wave generated in the impact process. Thus the strength of the shock wave that spreads to the second plate is reduced, and the damage in the SRW shields is alleviated. As the impact velocity increases, the main damage mode on the rear wall will change from the penetration damage mode to the impact damage mode, and the propagation of shock wave will be the main reason for the damage of the rear wall, which leads to better protecting performance of the SRW shields at higher impact velocities.-

Key words:

- space debris /

- Whipple shield /

- hypervelocity impact /

- rear wall

-

表 1 3种防护结构尺寸参数

Table 1. The sizes of three kinds of shields

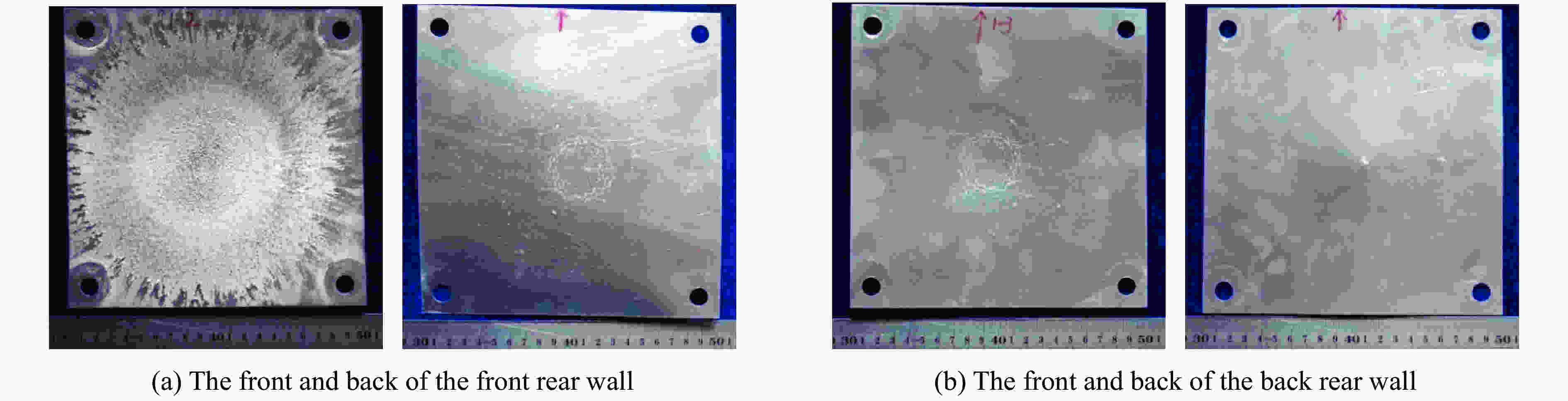

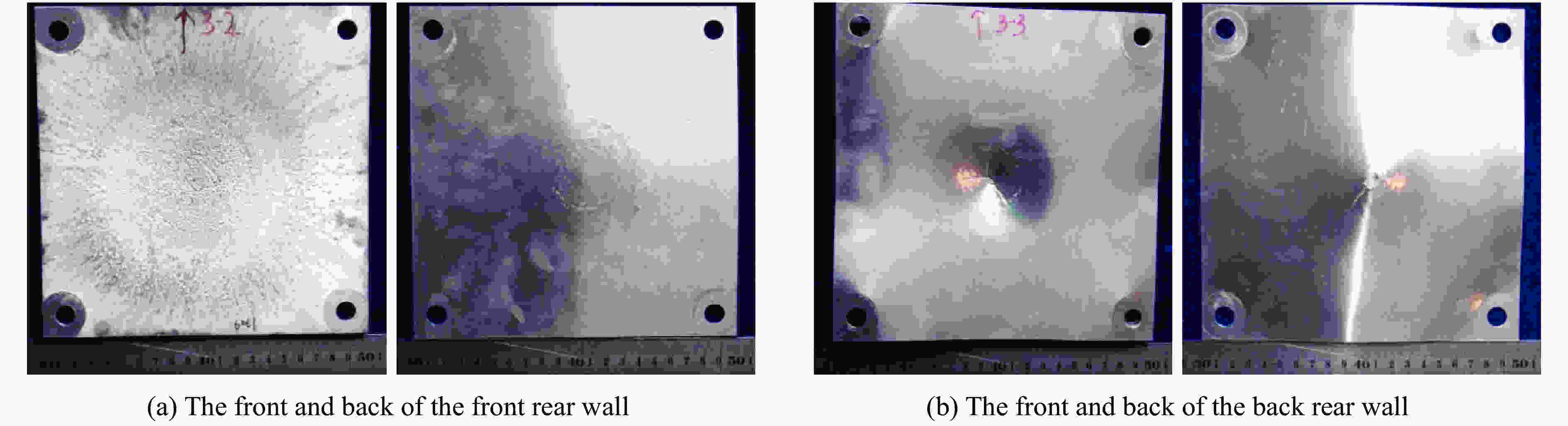

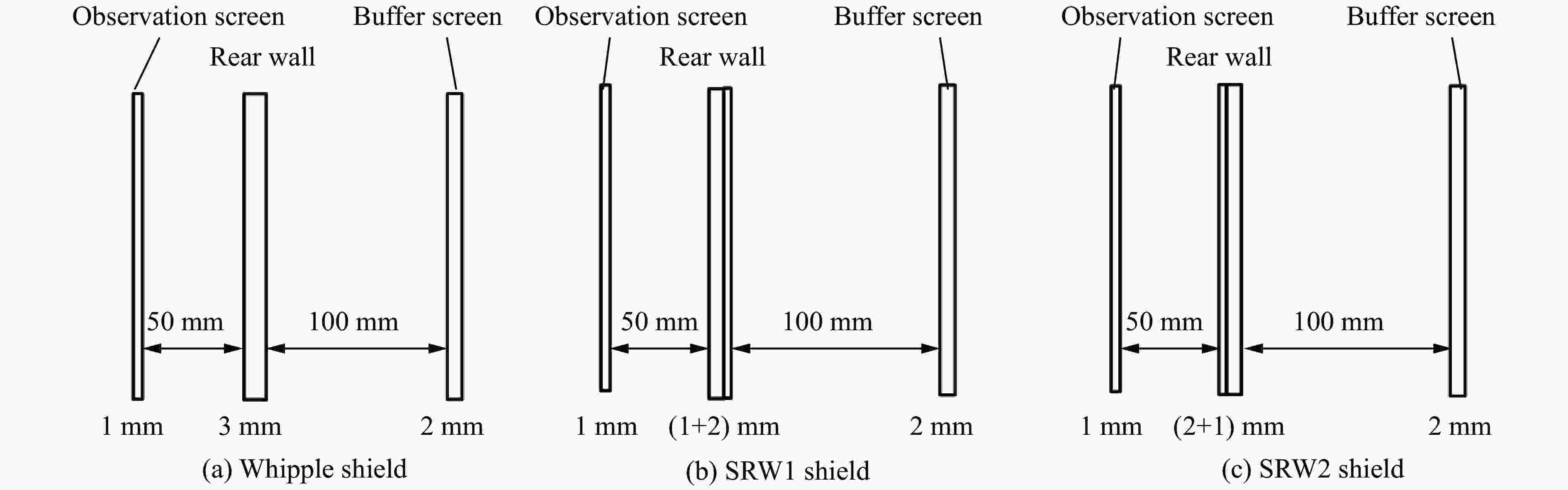

防护结构 缓冲屏与后墙间距/mm 缓冲屏厚度/mm 后墙结构 Whipple 100 2 厚度3 mm铝板 SRW1 100 2 第1层为厚度1 mm的铝板,第2层为厚度2 mm的铝板 SRW2 100 2 第1层为厚度2 mm的铝板,第2层为厚度1 mm的铝板 表 2 实验中3种防护结构损伤情况

Table 2. The damage of three kinds of shields in tests

防护结构 弹丸直径/mm 撞击速度/(km·s−1) 缓冲屏损伤 后墙损伤 观察屏损伤 Whipple 6.0 8.31 穿孔 约$\varnothing $35 mm剥落 撞击痕迹、鼓包 SRW1 6.0 8.25 穿孔 第1层:鼓包、无剥落 无痕迹 第2层:鼓包、无剥落 SRW2 6.0 8.41 穿孔 第1层:鼓包、无剥落 无痕迹 第2层:约$\varnothing $9 mm剥落 -

[1] 韩增尧, 庞宝君. 空间碎片防护研究最新进展 [J]. 航天器环境工程, 2012, 29(4): 369–378. DOI: 10.3969/j.issn.1673-1379.2012.04.004.HAN Z Y, PANG B J. Review of recent development of space debris protection research [J]. Spacecraft Environment Engineering, 2012, 29(4): 369–378. DOI: 10.3969/j.issn.1673-1379.2012.04.004. [2] NASA Johnson Space Center. Handbook for designing MMOD protection: NASA/TM-2009-214785 [R]. 2009. [3] 侯明强, 龚自正, 徐坤博, 等. 密度梯度薄板超高速撞击特性的实验研究 [J]. 物理学报, 2014, 63(2): 024701. DOI: 10.7498/aps.63.024701.HOU M Q, GONG Z Z, XU K B, et al. Experimental study on hypervelocity impact characteristics of density-grade thin-plate [J]. Acta Physica Sinica, 2014, 63(2): 024701. DOI: 10.7498/aps.63.024701. [4] SCHONBERG W P, TULLOS R J. Spacecraft wall design for increased protection against penetration by orbital debris impacts [J]. AIAA Journal, 1991, 29(12): 2207–2214. DOI: 10.2514/3.10861. [5] HUANG X G, YIN C, HUANG J, et al. Hypervelocity impact of TiB2-based composites as front bumpers for space shield applications [J]. Materials and Design, 2016, 97: 473–482. DOI: 10.1016/j.matdes.2016.02.126. [6] 武强, 张庆明, 龙仁荣, 等. 含能材料防护屏在球形弹丸超高速撞击下的穿孔特性研究 [J]. 兵工学报, 2017, 38(11): 2126–2133. DOI: 10.3969/j.issn.1000-1093.2017.11.007.WU Q, ZHANG Q M, LONG R R, et al. Perforation characteristics of energetic material shield induced by hypervelocity impact of spherical projectile [J]. Acta Armamentarii, 2017, 38(11): 2126–2133. DOI: 10.3969/j.issn.1000-1093.2017.11.007. [7] FAHRENTHOLD E P, PARK Y K. Simulation of hypervelocity impact on aluminum-Nextel-Kevlar orbital debris shields [J]. International Journal of Impact Engineering, 2003, 29(1−10): 227–235. DOI: 10.1016/j.ijimpeng.2003.09.018. [8] RYAN S, HEDMAN T, CHRISTIANSEN E L. Honeycomb vs. foam: evaluating potential upgrades to ISS module shielding [J]. Acta Astronautica, 2010, 67(7/8): 818–825. DOI: 10.1016/j.actaastro.2010.05.021. [9] CHRISTIANSEN E L, KERR J H. Mesh double-bumper shield: a low-weight alternative for spacecraft meteoroid and orbital debris protection [J]. International Journal of Impact Engineering, 1993, 14(1−3): 169–180. DOI: 10.1016/0734-743X(93)90018-3. [10] 哈跃, 刘志勇, 管公顺, 等. 玄武岩纤维布超高速撞击损伤分析 [J]. 高压物理学报, 2012, 26(5): 557–563. DOI: 10.11858/gywlxb.2012.05.012.HA Y, LIU Z Y, GUAN G S, et al. Damage investigation of hypervelocity impact on woven fabric of basalt fiber [J]. Chinese Journal of High Pressure Physics, 2012, 26(5): 557–563. DOI: 10.11858/gywlxb.2012.05.012. [11] 赵君尧, 柳森, 文雪忠, 等. 玻璃钢空间碎片防护构型性能的实验研究与仿真分析 [J]. 航天器环境工程, 2019, 36(2): 120–125. DOI: 10.12126/see.2019.02.003.ZHAO J Y, LIU S, WEN X Z, et al. Experimental and analytical studies of the performance of FRP protective configuration against space debris [J]. Spacecraft Environment Engineering, 2019, 36(2): 120–125. DOI: 10.12126/see.2019.02.003. [12] 管公顺, 丰硕, 庞宝君, 等. 三层铝板结构高速撞击损伤与极限特性 [J]. 宇航学报, 2016, 37(3): 364–370. DOI: 10.3873/j.issn.1000-1328.2016.03.016.GUAN G S, FENG S, PANG B J, et al. Damage and ballistic limit for three-layer aluminum plate structure under high-velocity impact [J]. Journal of Astronautics, 2016, 37(3): 364–370. DOI: 10.3873/j.issn.1000-1328.2016.03.016. [13] WEN X Z, HUANG J, KE F W, et al. Debris dispersion effect in N-shape configuration [J]. Acta Astronautica, 2014, 104(1): 173–178. DOI: 10.1016/j.actaastro.2014.06.037. [14] WEN X Z, HUANG J, KE F W, et al. Preliminary study on shielding performance of debris shield with the rear wall combining light materials and an aluminum plate [J]. International Journal of Impact Engineering, 2019, 124: 31–36. DOI: 10.1016/j.ijimpeng.2018.10.006. [15] WEN X Z, HUANG J, MA Z X, et al. Shielding performance of debris shield with separated rear wall [J]. International Journal of Impact Engineering, 2020, 137: 103446. DOI: 10.1016/j.ijimpeng.2019.103446. [16] 柳森, 黄洁, 李毅, 等. 中国空气动力研究与发展中心的空间碎片超高速撞击试验研究进展 [J]. 载人航天, 2011, 17(6): 17–23. DOI: 10.3969/j.issn.1674-5825.2011.06.004.LIU S, HUANG J, LI Y, et al. Recent advancement of hypervelocity impact tests at HAI, CARDC [J]. Manned Spaceflight, 2011, 17(6): 17–23. DOI: 10.3969/j.issn.1674-5825.2011.06.004. -

下载:

下载: