| [1] |

ASAY B. Shock wave science and technology reference library, Vol. 5: non-shock initiation of explosives [M]. Springer Science & Business Media, 2010: 1−14.

|

| [2] |

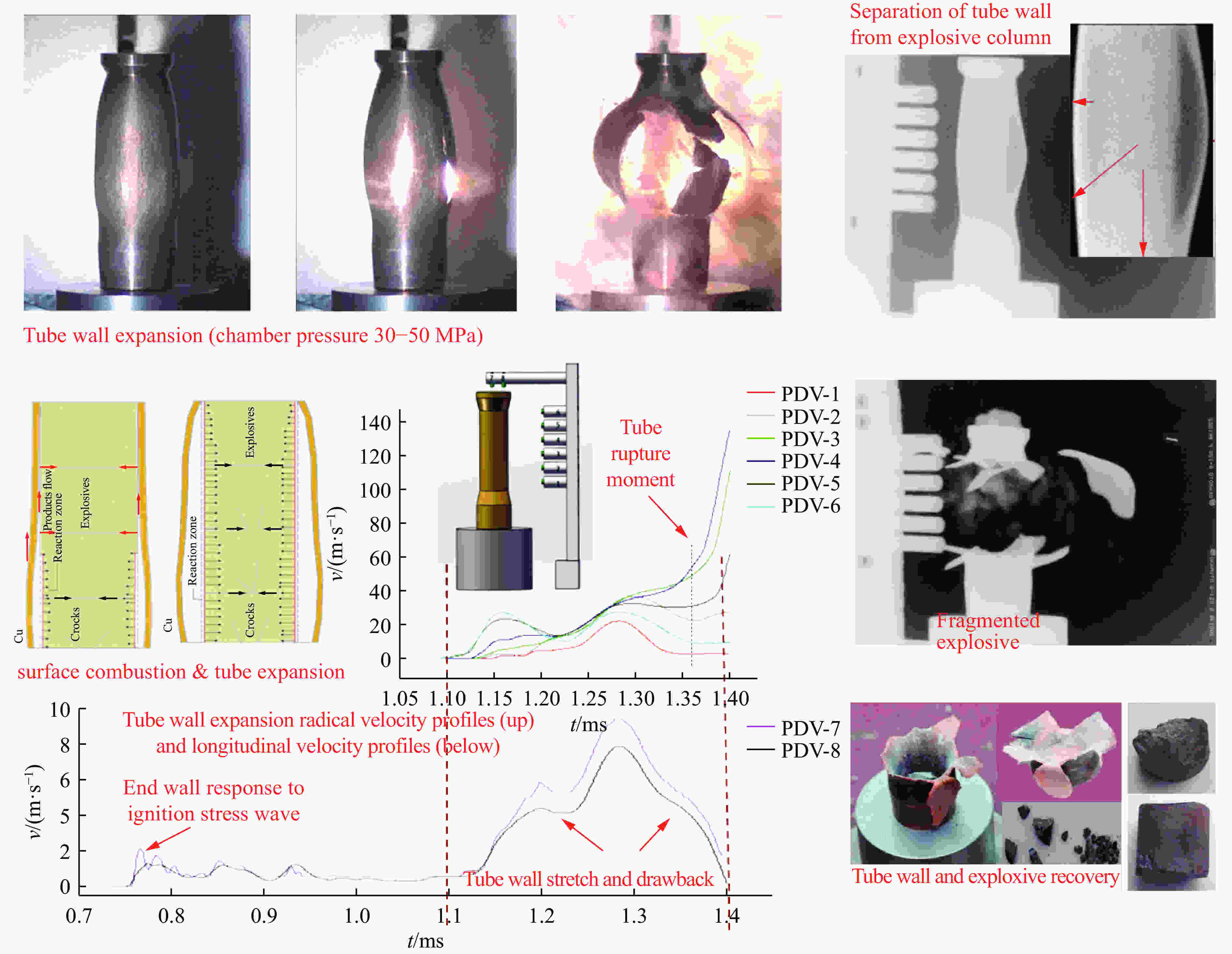

胡海波, 郭应文, 傅华, 等. 炸药事故反应烈度转化的主控机制 [J]. 含能材料, 2016, 24(7): 622–624. DOI: 10.11943/j.issn.1006-9941.2016.07.00X.HU H B, GUO Y W, FU H, et al. The dominant mechanisms of reaction violence transition in explosive accidents [J]. Chinese Journal of Energetic Materials, 2016, 24(7): 622–624. DOI: 10.11943/j.issn.1006-9941.2016.07.00X.

|

| [3] |

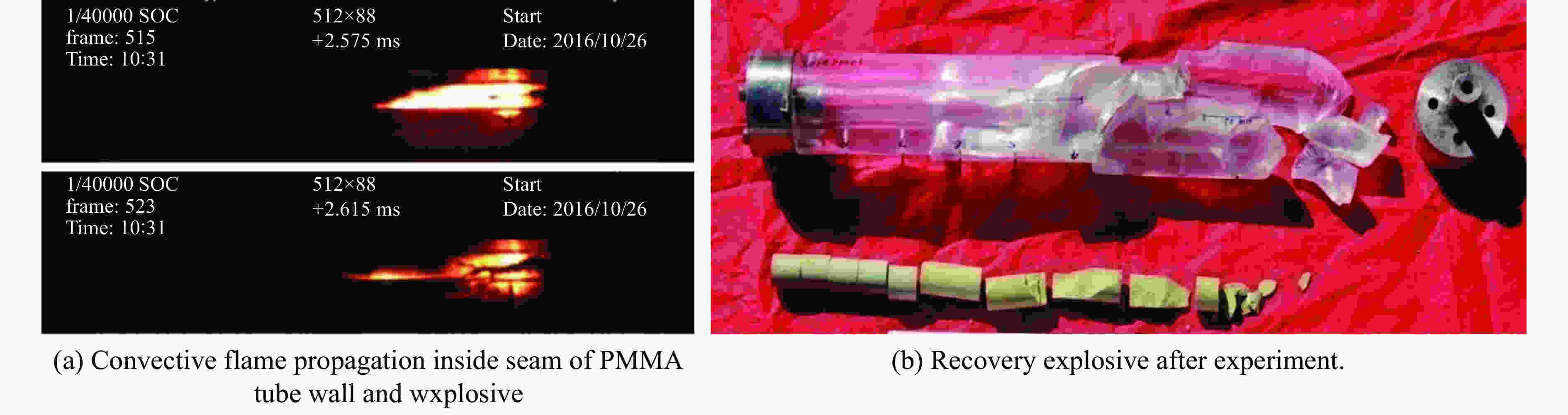

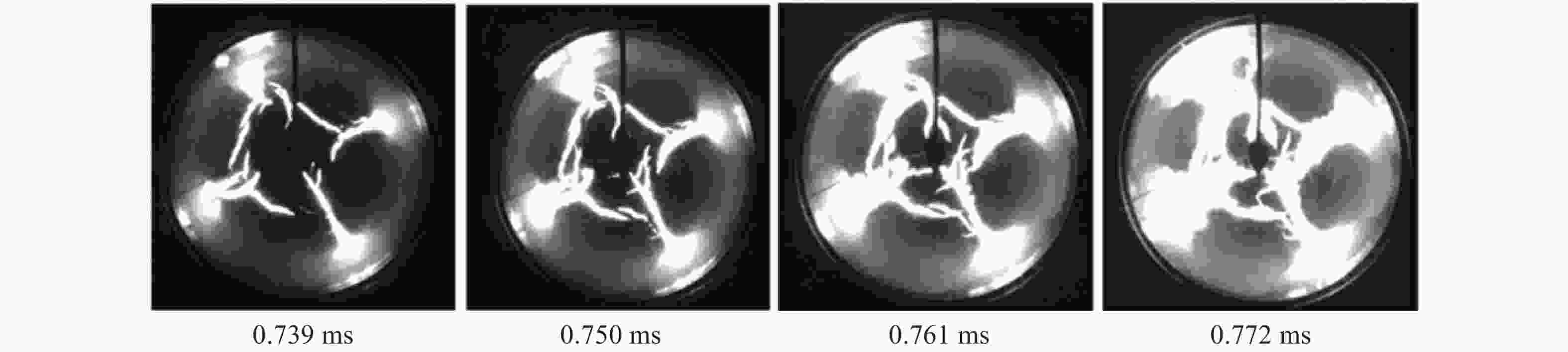

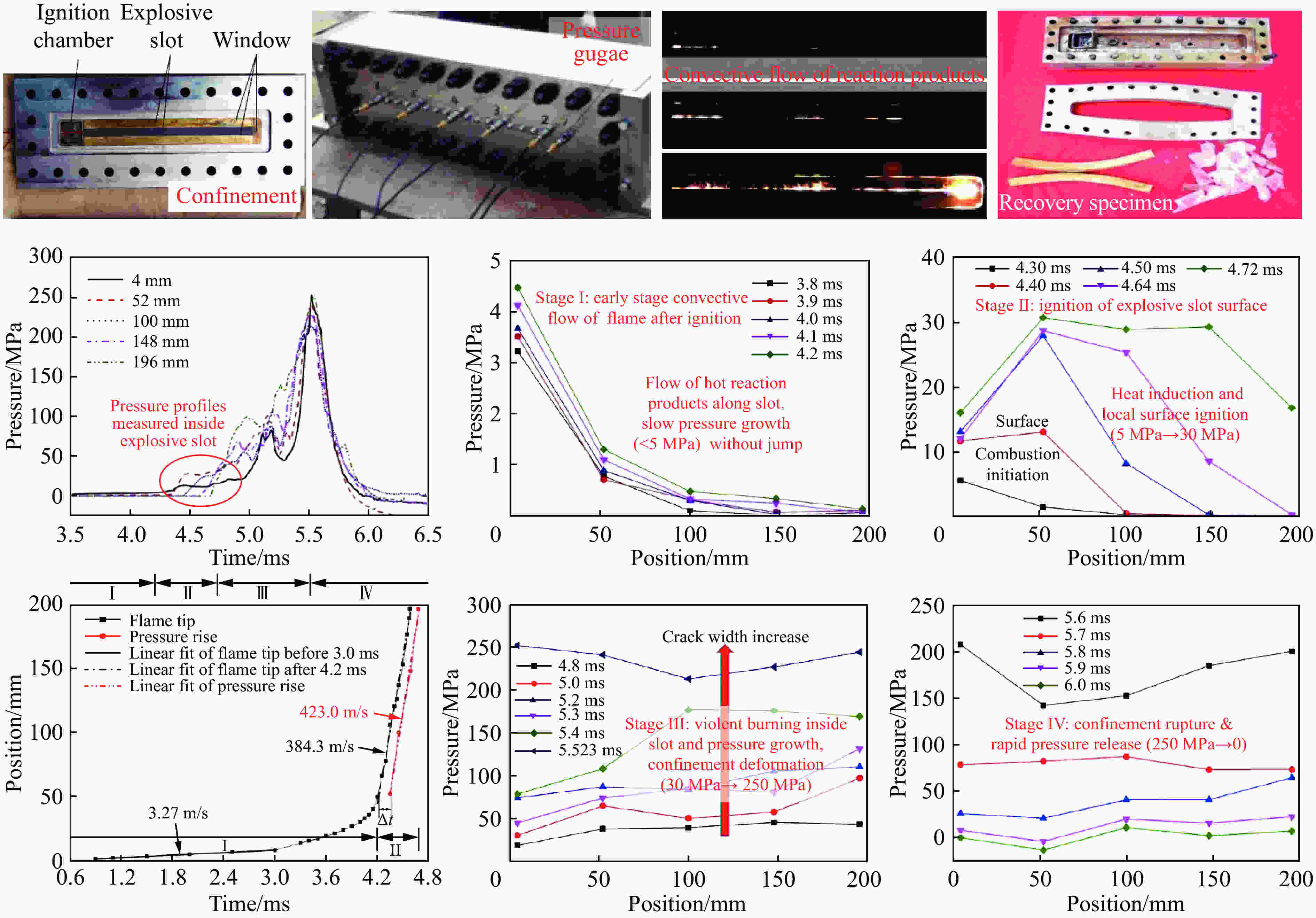

SHANG H L, YANG J, LI T, et al. Convective burning in confined explosive cracks of HMX-based PBX under non-shock initiation [C] // 16th International Detonation Symposium. Hawaii, 2018.

|

| [4] |

郭应文. 压装PBX反应烈度演化主导机制的实验研究[D]. 四川绵阳: 中国工程物理研究院, 2017.

|

| [5] |

HU H, GUO Y, LI T, et al. Reactive behavior of explosive billets in deflagration tube of varied confinements [C] // AIP Conference Proceedings. AIP Publishing, 2018, 1979(1): 150020.

|

| [6] |

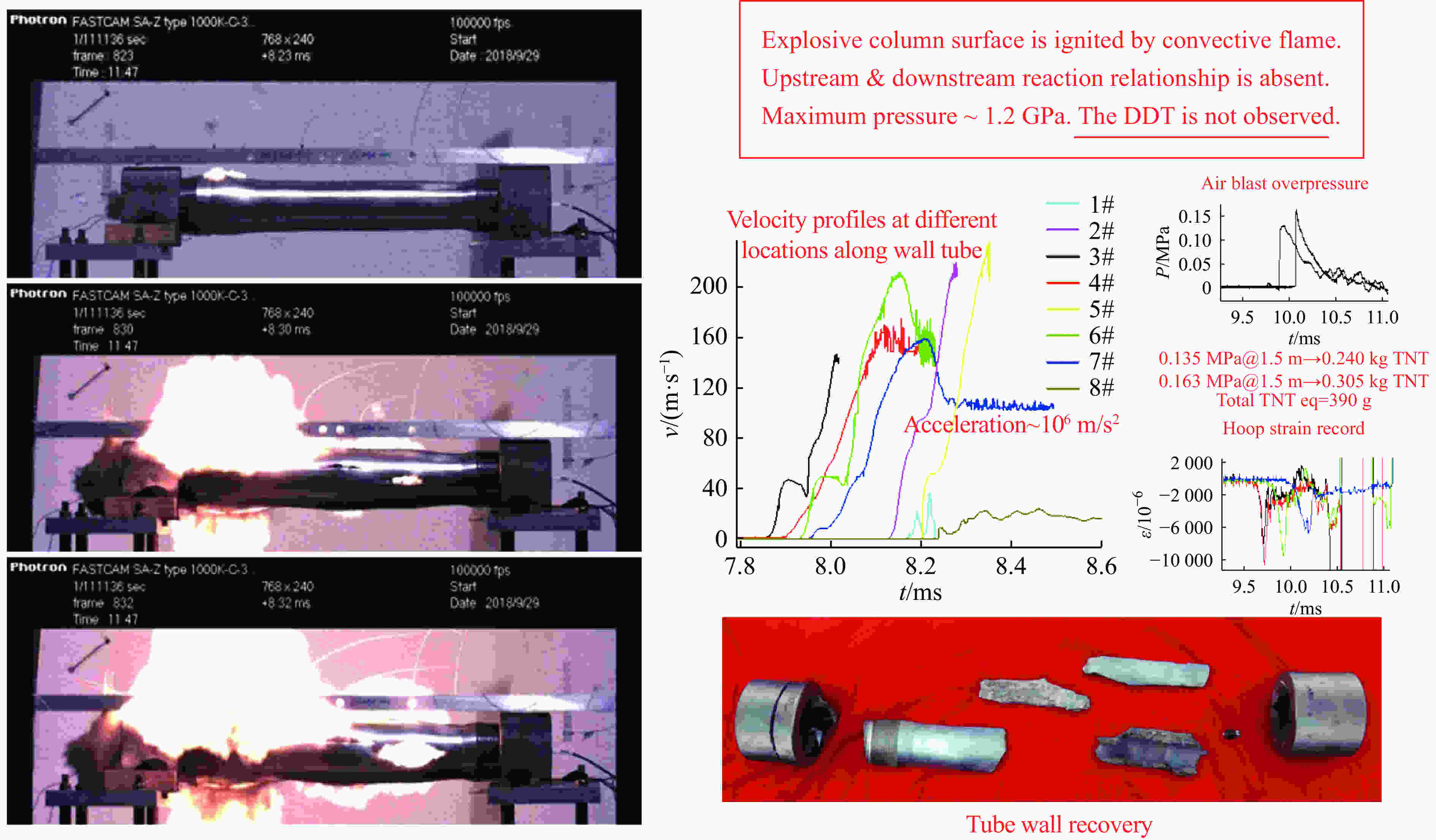

HU H B, LI T, WEN S G, et al. Experimental study on the reaction evolution of pressed explosives in long thick wall cylinder confinement [C] // XXI Khariton’s Scientific Readings. Sarov, Russia, 2019.

|

| [7] |

LI T, GUO Y W, FU H, et al. Reaction cracks and pressurization of a pressed HMX-based PBX under high confinement [C] // 49th International Annual Conference of ICT, 2018.

|

| [8] |

LI T, HU H B, QIU T, et al. Experimentas of violent reactions of pressed high explosive in thick wall confinement [C] // XXI Khariton’s Scientific Readings, Sarov, Russia, 2019.

|

| [9] |

WEN Y, DAI X, HAN Y, et al. Reaction characteristic for various scale explosive under mild impact [J]. Journal of Energetic Materials, 2014, 32(S1): 41–50. DOI: 10.1080/07370652.2013.820808.

|

| [10] |

BAER M R, KIPP M E, SCHMITT R G, et al. Towards assessing the violence of reaction during cookoff of confined energetic materials [R]. Albuquerque, New Mexico, United States: Sandia National Laboratories, 1996.

|

| [11] |

NICHOLS III A L, COUCH R, MCCALLEN R C, et al. Modeling thermally driven energetic response of high explosives [C] // Proceedings of 11th International Detonation Symposium, 1998: 862−871.

|

| [12] |

REAUGH J E. HERMES: a model to describe deformation, burning, explosion, and detonation [R]. Livermore, California, United States: Lawrence Livermore National Laboratory, 2011.

|

| [13] |

陈朗, 王飞, 伍俊英, 等. 高密度压装炸药燃烧转爆轰研究 [J]. 含能材料, 2011, 19(6): 697–704. DOI: 10.3969/j.issn.1006-9941.2011.06.022.CHEN L, WANG F, WU J Y, et al. Investigation of the deflagration to detonation transition in pressed high density explosives [J]. Chinese Journal of Energetic Materials, 2011, 19(6): 697–704. DOI: 10.3969/j.issn.1006-9941.2011.06.022.

|

| [14] |

陈朗, 马欣. 炸药热安全性理论与分析方法[M]. 北京: 国防工业出版社, 2015.

|

| [15] |

薛鸿陆. 爆轰波基础知识 [J]. 爆炸与冲击, 1983, 3(1): 89–96.XUE H L. Fundamental knowledge of detonation waves [J]. Explosion and Shock Waves, 1983, 3(1): 89–96.

|

| [16] |

ZENIN A, FINJAKOV S. Characteristics of octogen and hexogen combustion: a comparison [C] // 36th International Annual Conference of ICT, 2006.

|

| [17] |

MAIENSCHEIN J L, KOERNER J G. Deflagration behavior of PBX 9501 at elevated temperature and pressure [R]. Livermore, California, United States: Lawrence Livermore National Laboratory, 2008.

|

| [18] |

孙承纬, 范宝春, 黄正平, 等. 爆轰术语: GJB 5720-2006[S]. 2006.

|

| [19] |

SMILOWITZ L, HENSON B F, ROMERO J J, et al. Thermal explosions: sub-sonic deflagration in PBX 9501 [R]. Los Alamos, New Mexico, United States: Los Alamos National Laboratory, 2011.

|

| [20] |

SMILOWITZ L B, HENSON B F. Temperature measurements during sub-sonic thermal explosions [R]. Los Alamos, New Mexico, United States: Los Alamos National Laboratory, 2012.

|

| [21] |

奥尔连科. 爆炸物理学[M]. 孙承纬, 译. 北京: 科学出版社, 2011.

|

| [22] |

BELYAEV A F, BOBOLEV V K, KOROTKOV A I, et al. Transition from deflagration to detonation in condensed phases [J]. Israel Program for Scientific Translations, Jerulasem, 1975.

|

| [23] |

БЕЛЬСКИЙ В М. Механизм инициирования и развития детонации в твердых гетерогенных ВВ [M]. Sarov, 2019.

|

| [24] |

ANDREEVSKIKH L A, VAKHMISTROV S A, PRONIN D A, et al. Convective combustion in the slot of an explosive charge [J]. Combustion, Explosion, and Shock Waves, 2015, 51(6): 659–663. DOI: 10.1134/S0010508215060064.

|

| [25] |

Hazard assessment tests for non-nuclear munitions: MIL-STD-2105D [S]. Indian Head, MD : Department of Defense, 2011.

|

| [26] |

JOHANSSON S R. Clear thinking requires clear concepts and terms (Explosion: disruption of a container. A mechanical term, not chemical) [C] // 含能材料与钝感弹药技术研讨会论文集. 成都, 2014.

|

| [27] |

KUO K K, KOVALCIN R L, ACKMAN S J. Convective burning in isolated solid propellant cracks [R]. Government-Industry Data Exchange Program, 1979.

|

| [28] |

BERNECKER R. The deflagration-to-detonation transition process for high-energy propellants-a review [J]. AIAA Journal, 1986, 24(1): 82–91. DOI: 10.2514/3.9226.

|

| [29] |

MAČEK A. Transition from deflagration to detonation in cast explosives [J]. The Journal of Chemical Physics, 1959, 31(1): 162–167. DOI: 10.1063/1.1730287.

|

| [30] |

TARVER C M, GOODALE T C, SHAW R, et al. Deflagration-to-detonation transition studies for two potential isomeric cast primary explosives [C] // Proceeding of the Sixth Symposium (International) on Detonation. White Oak: Office of Naval Research, 1976: 231.

|

| [31] |

JACOBS S J. Comment on “deflagration-to-detonation transition studies for two potential isomeric cast primary explosives” [C] // Proceedings of the Sixth Symposium (International) on Detonation. Arlington, VA: Office of Naval Research, 1976: 249.

|

| [32] |

ASAY B. Shock wave science and technology reference library, Vol. 5: non-shock initiation of explosives [M]. Springer Science & Business Media, 2010: 483−533.

|

| [33] |

BERGHOUT H L, SON S F, ASAY B W. Convective burning in gaps of PBX 9501 [J]. Proceedings of the Combustion Institute, 2000, 28(1): 911–917. DOI: 10.1016/S0082-0784(00)80297-0.

|

| [34] |

JACKSON S I, HILL L G. Predicting runaway reaction in a solid explosive containing a single crack [C] // AIP Conference Proceedings, 2007, 955(1): 927−930.

|

| [35] |

HOLMES M D, PARKER Jr G R, HEATWOLE E M, et al. Center-ignited spherical-mass explosion (CISME); FY 2018 report [R]. Los Alamos, New Mexico, United States: Los Alamos National Laboratory, 2018.

|

| [36] |

HOLMES M D, PARKER Jr G R, HEATWOLE E M, et al. Fracture effects on explosive response (FEER); FY2018 report [R]. Los Alamos, New Mexico, United States : Los Alamos National Laboratory, 2018.

|

| [37] |

文尚刚. 炸药缝隙中燃烧模式转化及反应烈度增长行为研究[R]. 四川绵阳: 中国工程物理研究院, 2017.

|

| [38] |

DAI X G, WEN Y S, HUANG F L, et al. Effect of temperature, density and confinement on deflagration to detonation transition of an HMX‐based explosive [J]. Propellants, Explosives, Pyrotechnics, 2014, 39(4): 563–567. DOI: 10.1002/prep.201300112.

|

| [39] |

王建, 文尚刚. 以HMX为基的两种压装高密度炸药的燃烧转爆轰实验研究 [J]. 高压物理学报, 2009, 23(6): 441–446. DOI: 10.3969/j.issn.1000-5773.2009.06.007.WANG J, WEN S G. Experimental study on deflagration-to-detonation transition in two pressed high-density explosives [J]. Chinese Journal of High Pressure Physics, 2009, 23(6): 441–446. DOI: 10.3969/j.issn.1000-5773.2009.06.007.

|

| [40] |

王建, 文尚刚, 何智, 等. 压装高能炸药的燃烧转爆轰实验研究 [J]. 火炸药学报, 2009, 32(5): 25–28. DOI: 10.3969/j.issn.1007-7812.2009.05.008.WANG J, WEN S G, HE Z, et al. Experimental study on deflagration to detonation transition in pressed high density explosives [J]. Chinese Journal of Explosives and Propellants, 2009, 32(5): 25–28. DOI: 10.3969/j.issn.1007-7812.2009.05.008.

|

| [41] |

代晓淦, 申春迎, 文玉史. 模拟跌落撞击下PBX-2炸药的响应 [J]. 含能材料, 2011, 19(2): 209–212. DOI: 10.3969/j.issn.1006-9941.2011.02.019.DAI X G, SHEN C Y, WEN Y S. Reaction of PBX-2 explosive under simulated drop impact [J]. Chinese Journal of Energetic Materials, 2011, 19(2): 209–212. DOI: 10.3969/j.issn.1006-9941.2011.02.019.

|

| [42] |

李涛. 低幅值冲击条件下带壳炸药反应烈度的研究[D]. 四川绵阳: 中国工程物理研究院, 2003.

|

| [43] |

李克武, 尚海林, 胡秋实, 等. 针对PBX炸药的SHPB实验方法改进与结果解读[C] // 第十四届全国物理力学学术会议缩编文集. 四川绵阳, 2016.

|

下载:

下载: