J-C model of high-entropy alloy Ta-Hf-Nb-Zr system and its application test

-

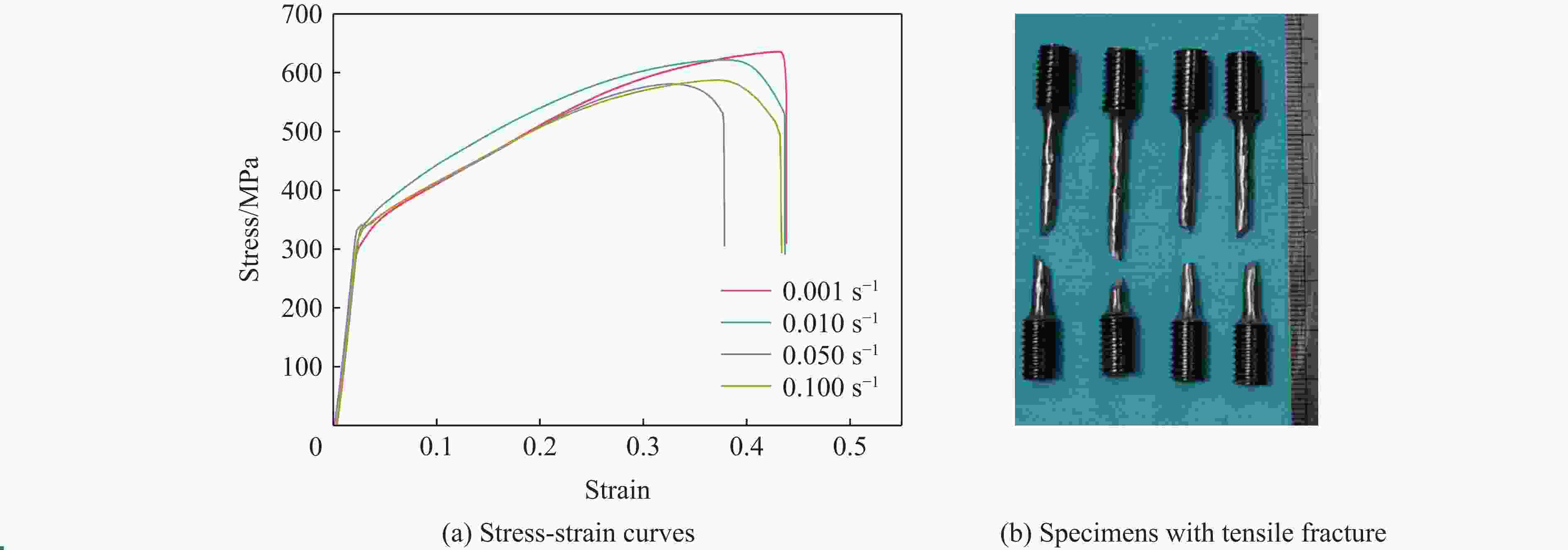

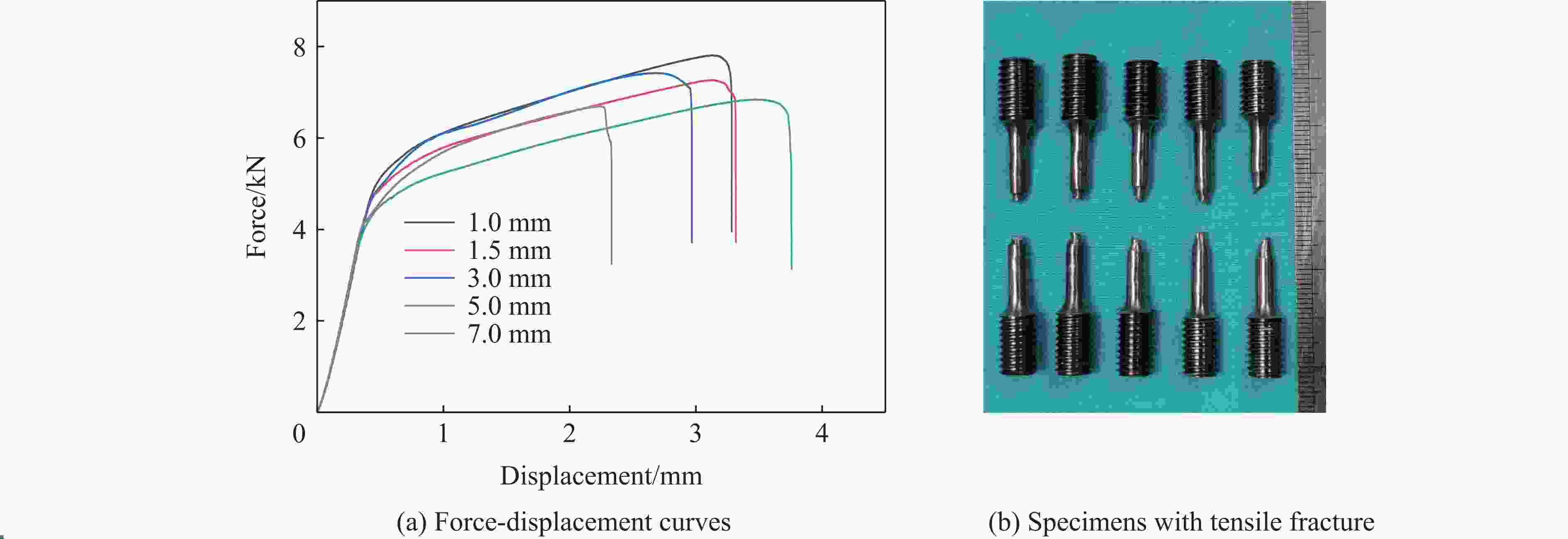

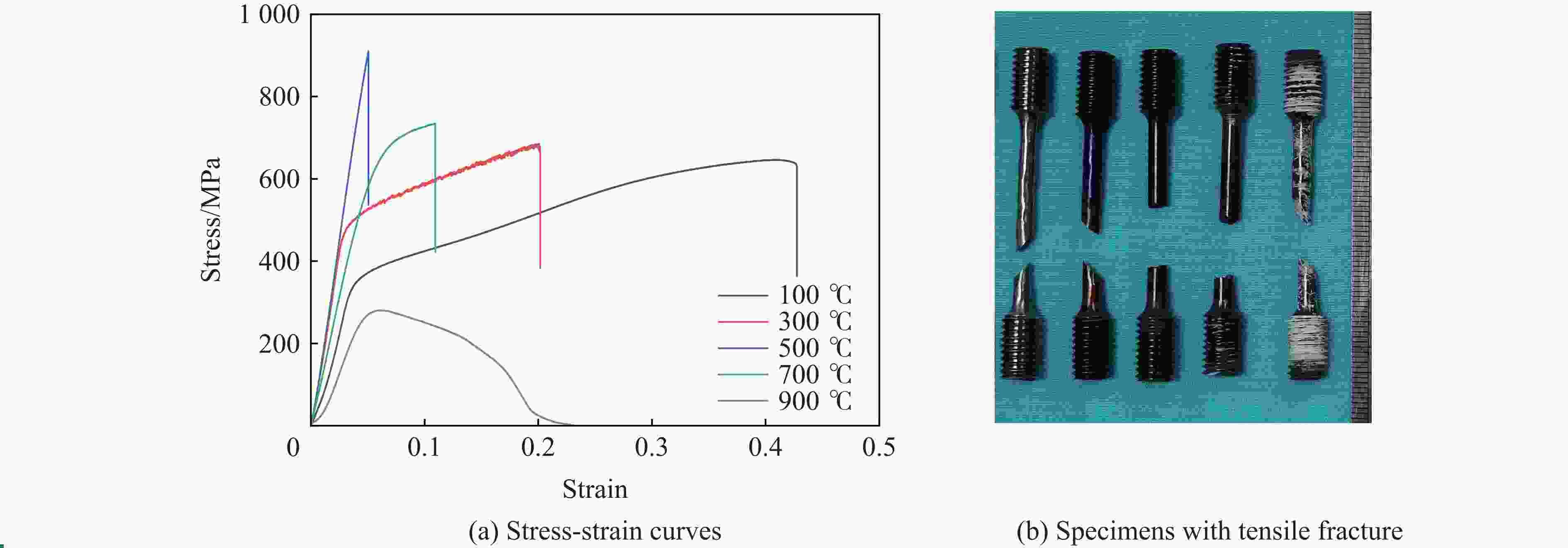

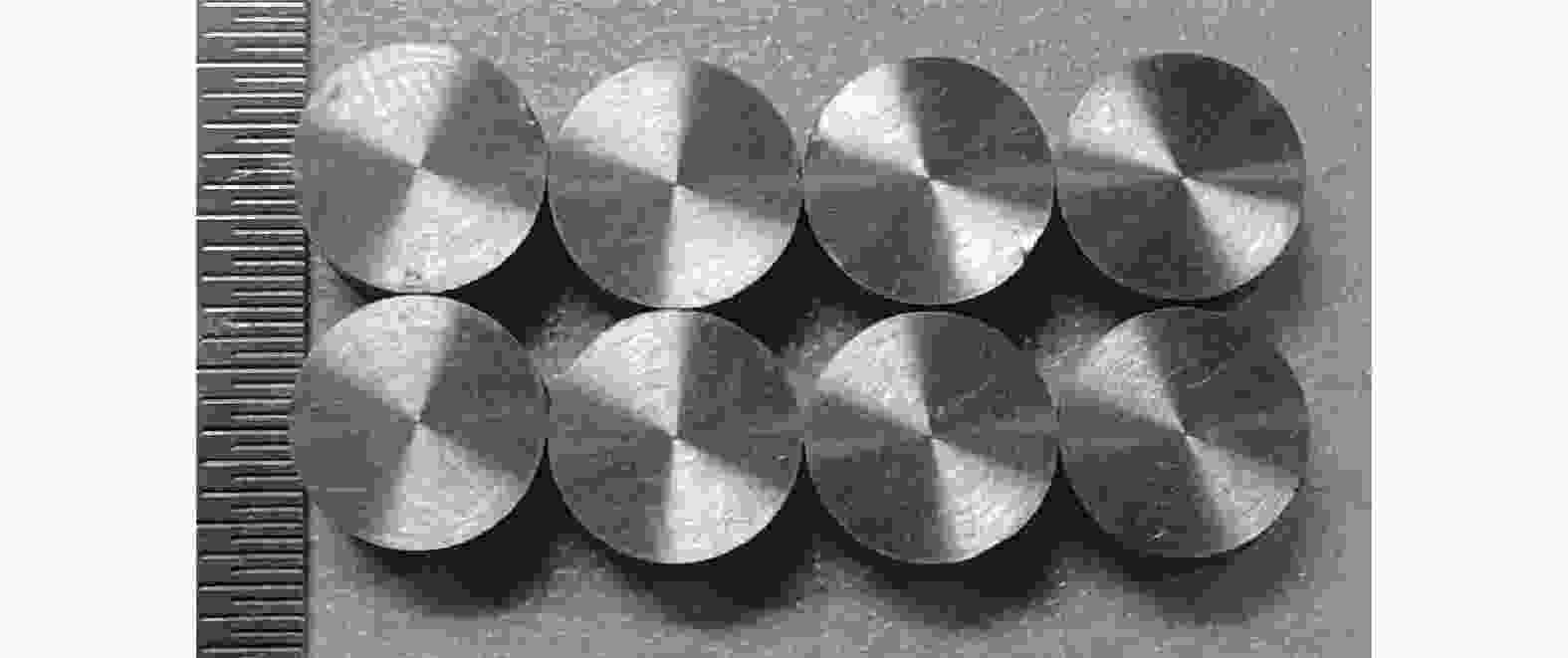

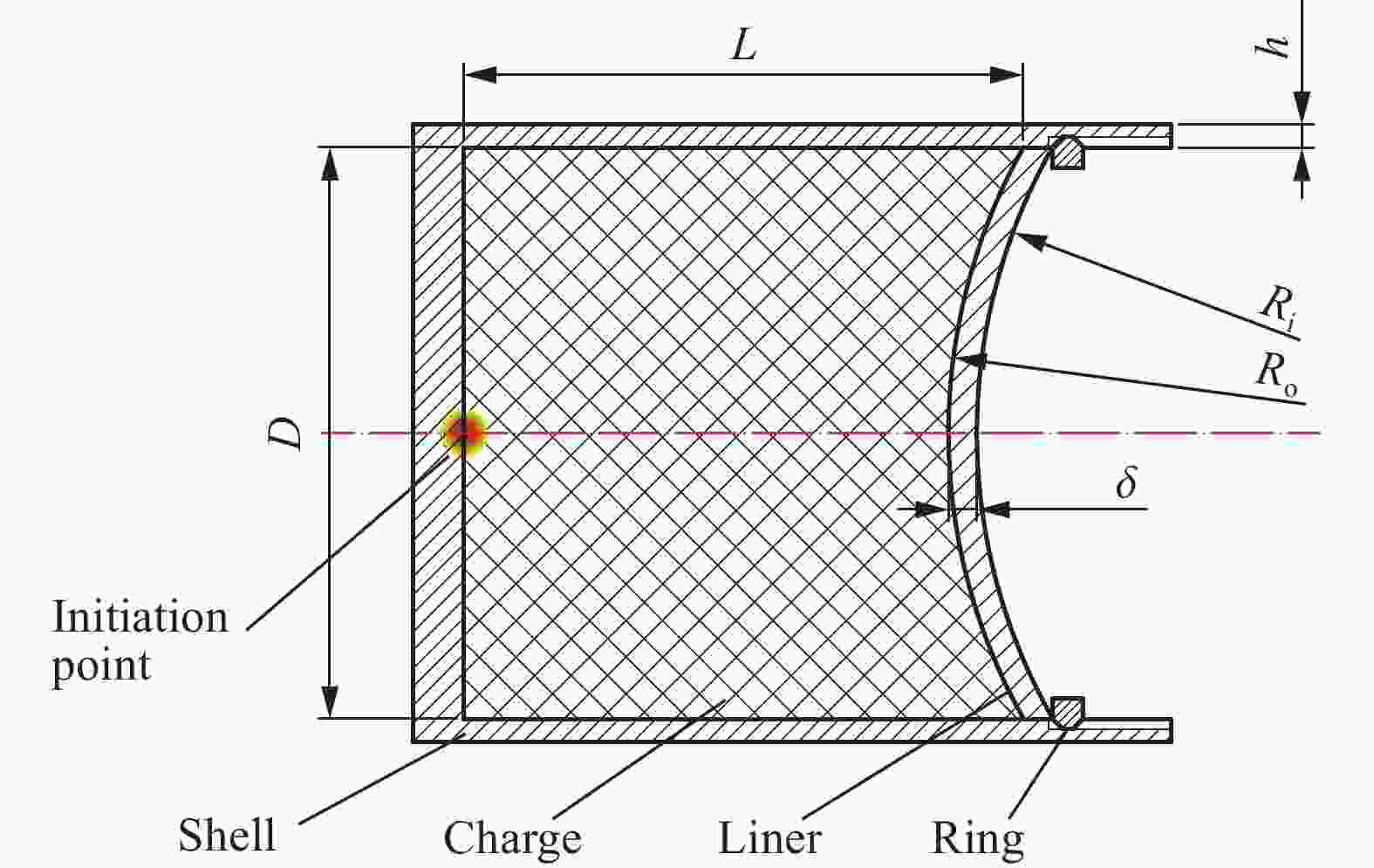

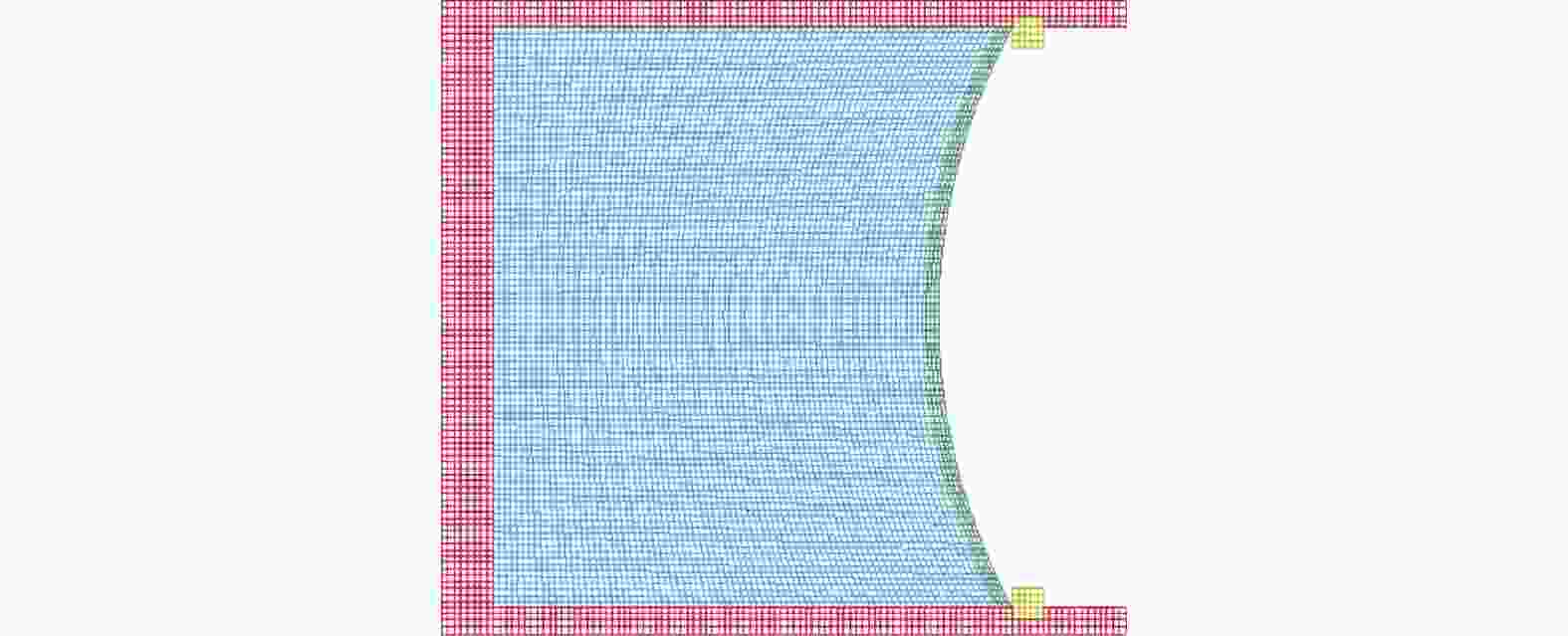

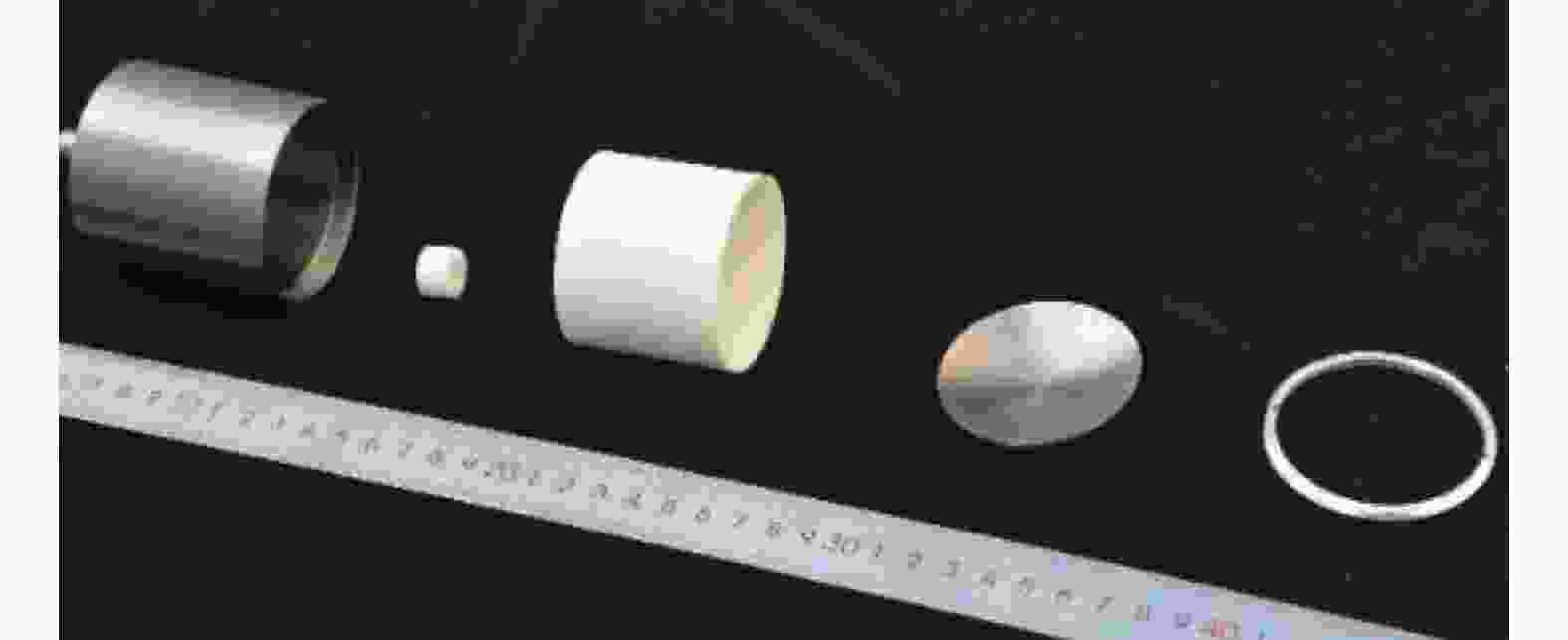

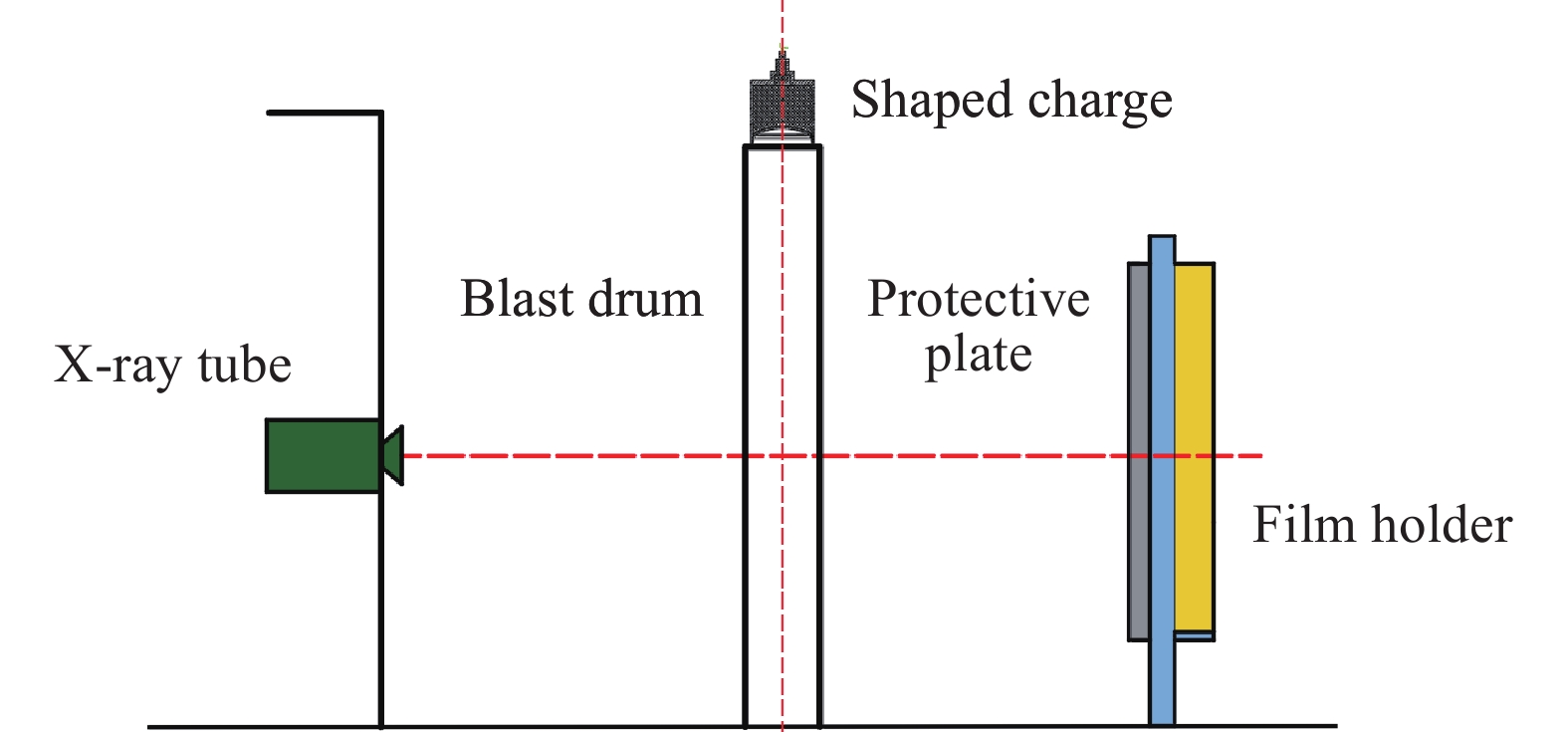

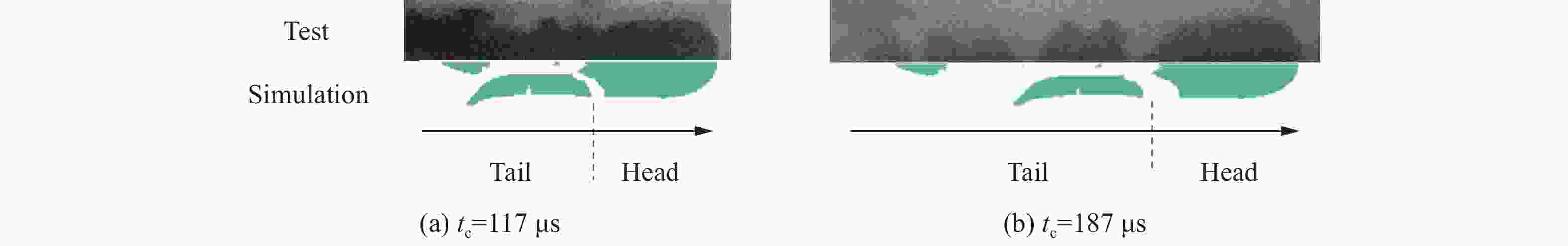

摘要: 针对包含高密度、高热值元素的高熵合金材料在聚能战斗部药型罩上的应用问题,选取Ta-Hf-Nb-Zr体系高熵合金为研究对象,采用INSTRON材料试验机、分离式霍普金森压杆试验平台,探寻该高熵合金在应变率为10−3~103 s−1、温度为25~900 ℃以及应力三轴度为0.33~0.89条件下的力学响应规律,基于静动态力学性能试验结果,获取该合金的Johnson-Cook(J-C)本构方程参数及损伤失效模型参数,并建立爆炸加载下高熵合金爆炸成型弹丸(explosively formed projectile,EFP)数值模型。开展EFP成型脉冲X射线验证试验,结果显示:117 μs时,高熵合金EFP成型较为完整,EFP长度为51.1 mm,直径为12.27 mm;187 μs时,EFP尾部产生3处断裂,头部长度为24.3 mm,直径为12.27 mm,EFP速度为

2496.3 m/s。模拟与试验的EFP长度、直径以及速度的误差均小于8.2%,模拟的断裂形态与试验结果基本一致,J-C模型有效预测了爆炸加载条件下高熵合金EFP的成型状态。-

关键词:

- 高熵合金 /

- Johnson-Cook模型 /

- 爆炸成型弹丸 /

- 脉冲X射线

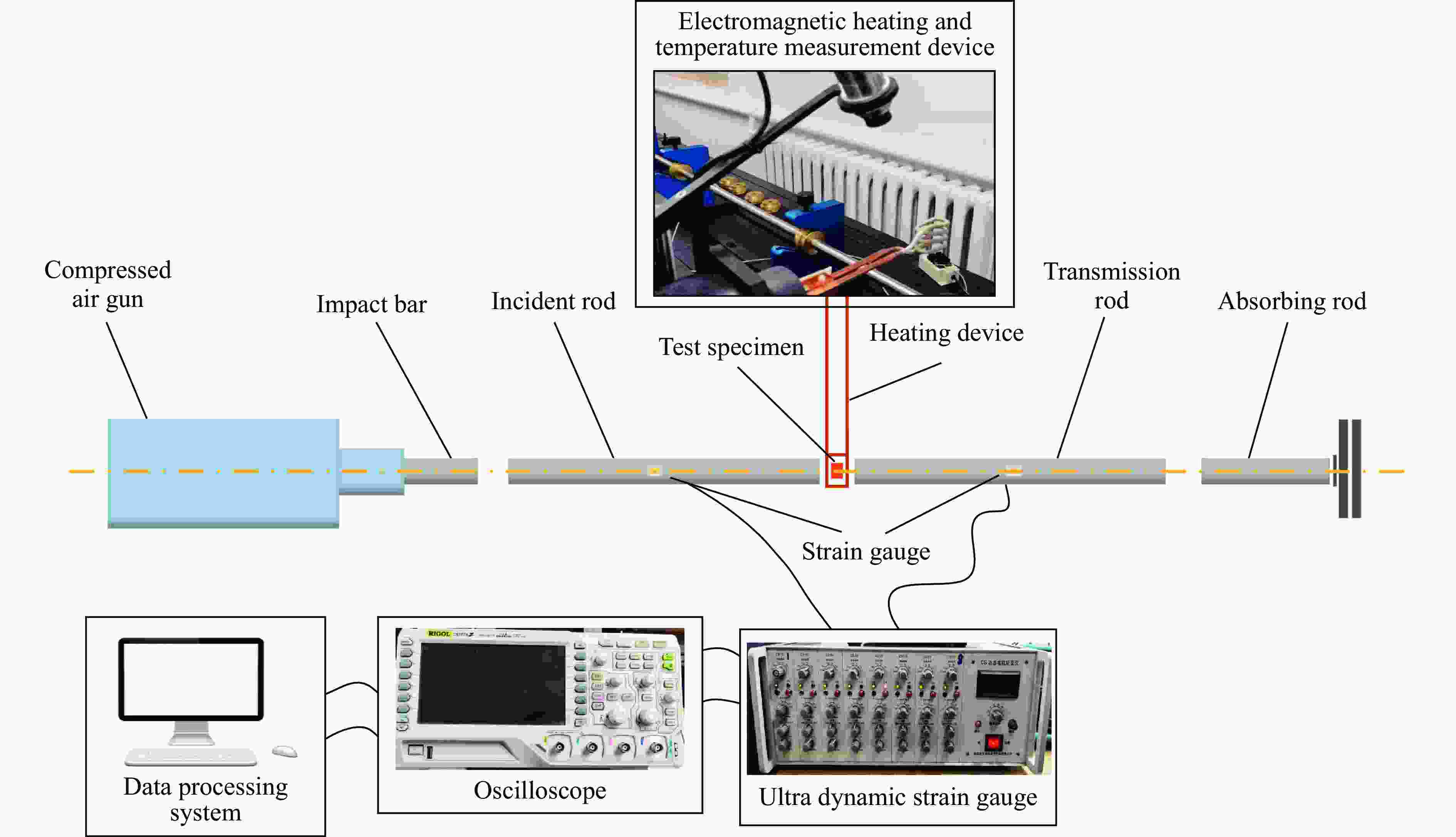

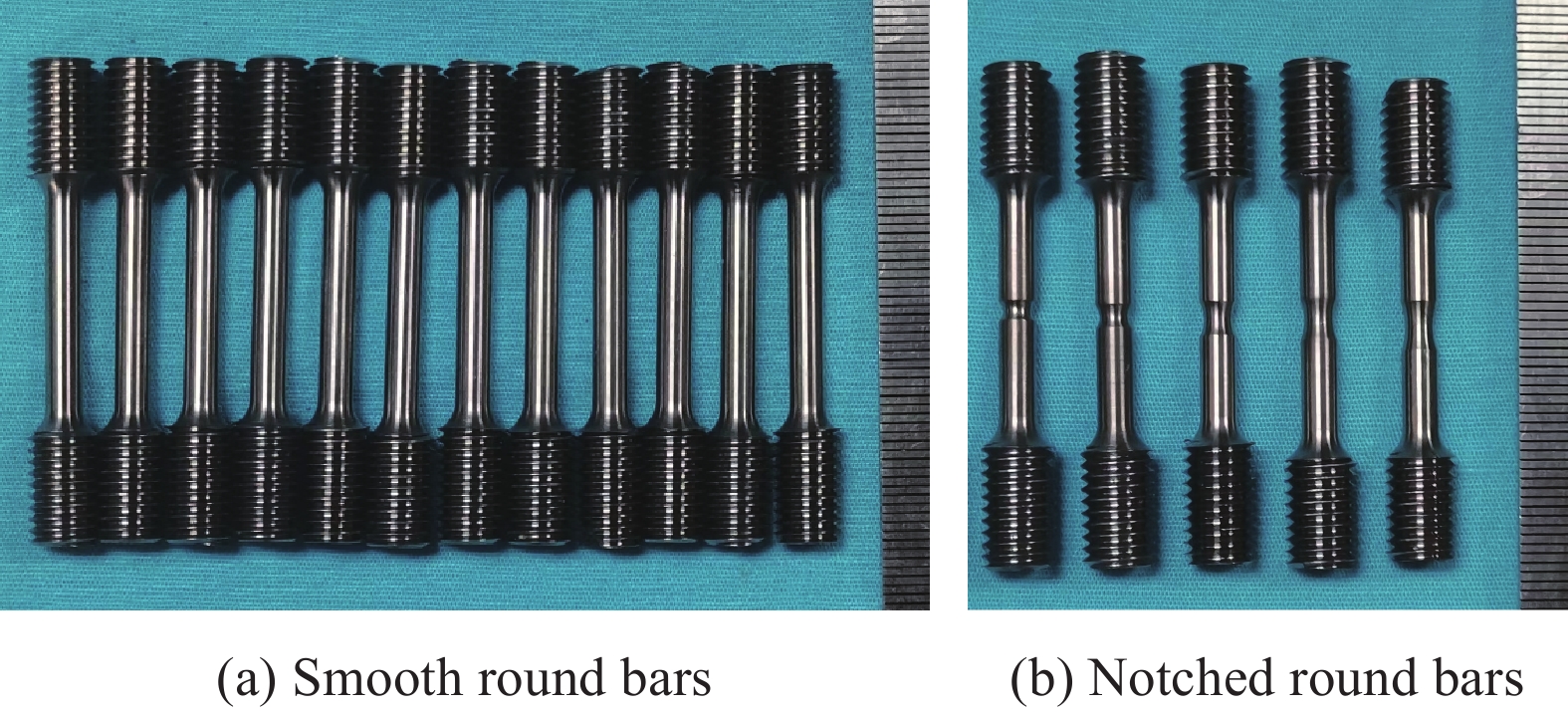

Abstract: In relation to the application of high-entropy alloy systems containing high-density and high-calorific value elements in the liner of shaped charge warheads, the Ta-Hf-Nb-Zr high-entropy alloy system is investigated. The study employed an INSTRON material testing machine and a split Hopkinson pressure bar testing platform to explore the mechanical response of this high-entropy alloy across a wide range of strain rates from 10−3 to 103 s−1, temperatures ranging from 25 to 900 °C, and stress triaxiality values ranging from 0.33 to 0.89. Yield strength and failure strain data were obtained from static round bar tensile tests and dynamic compression tests conducted under these varying conditions. By using least squares fitting, the parameters of the Johnson-Cook (J-C) constitutive equation as well as the damage failure model parameters, are derived. Subsequently, a simulation model for explosively formed projectile (EFP) made from high-entropy alloys under explosive loading conditions was developed. Pulse X-ray tests of the EFP formation were performed, and numerical simulations of the EFP formation process are conducted using LS-DYNA software. The results show that at 117 μs, the high-entropy alloy EFP remains largely intact, with a length of 51.1 mm and a diameter of 12.27 mm. At 187 μs, three fractures are observed at the tail of the EFP, with the head length measuring 24.3 mm, the diameter at 12.27 mm, and the EFP speed recorded at2496.3 m/s. The numerical simulations demonstrate that the EFP length, diameter, and velocity at these time instants match the test data with errors of less than 8.2%. Moreover, the fracture patterns observed experimentally align closely with those predicted by the simulations. This consistency indicates that the J-C model effectively predicts the formation characteristics of high-entropy alloy EFPs under explosive loading conditions, confirming its utility in accurately simulating the EFP formation process.-

Key words:

- high-entropy alloy /

- Johnson-Cook model /

- explosively formed projectile /

- pulsed X-ray

-

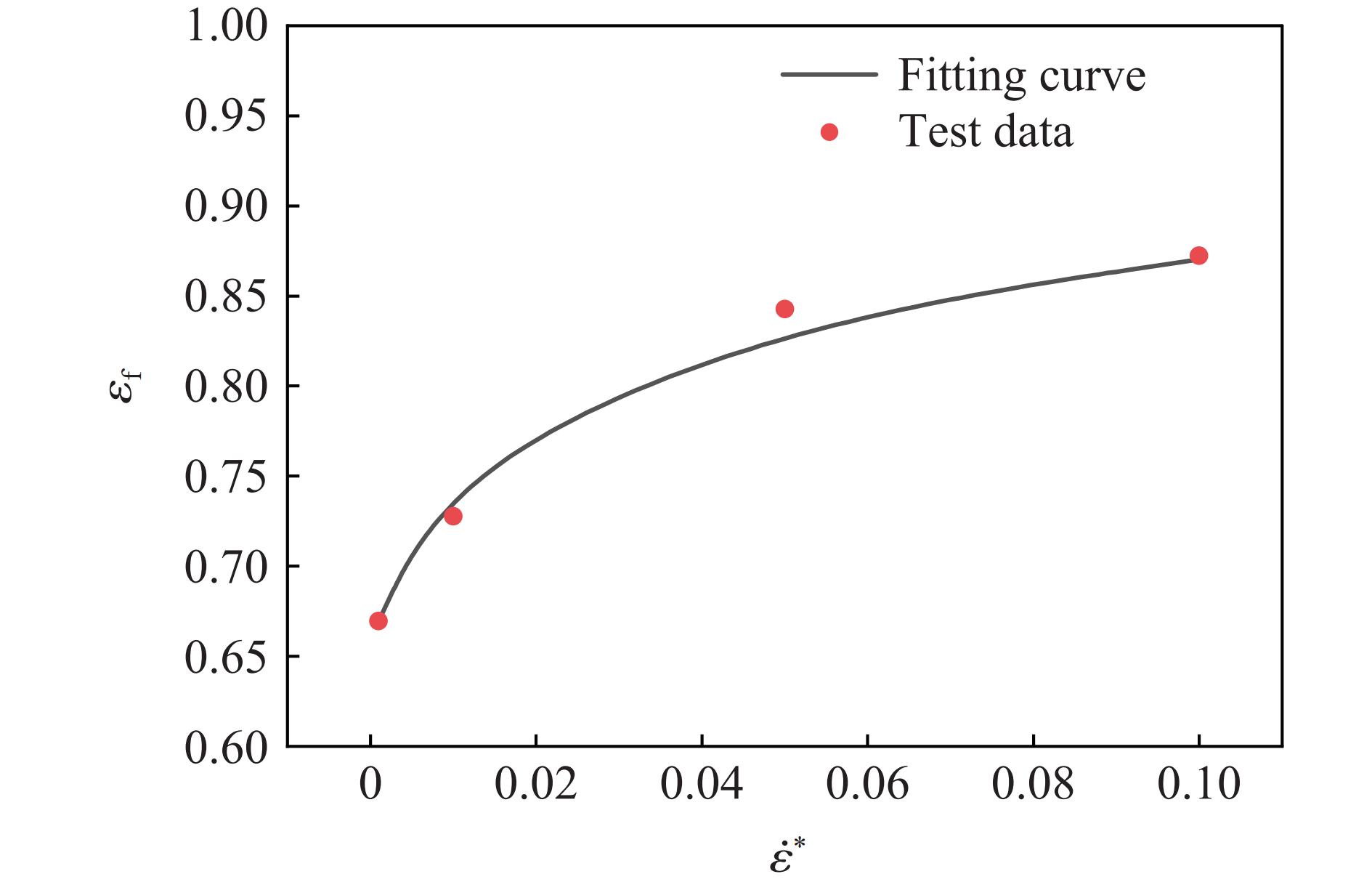

表 1 不同应变率下光滑圆棒试件的失效应变

Table 1. Failure strain of smooth round bar specimens at different strain rates

试件编号 应变率/s−1 εf 1-1 0.001 0.67 1-2 0.010 0.73 1-3 0.050 0.86 1-4 0.100 0.87 表 2 不同缺口半径下缺口试件的失效应变

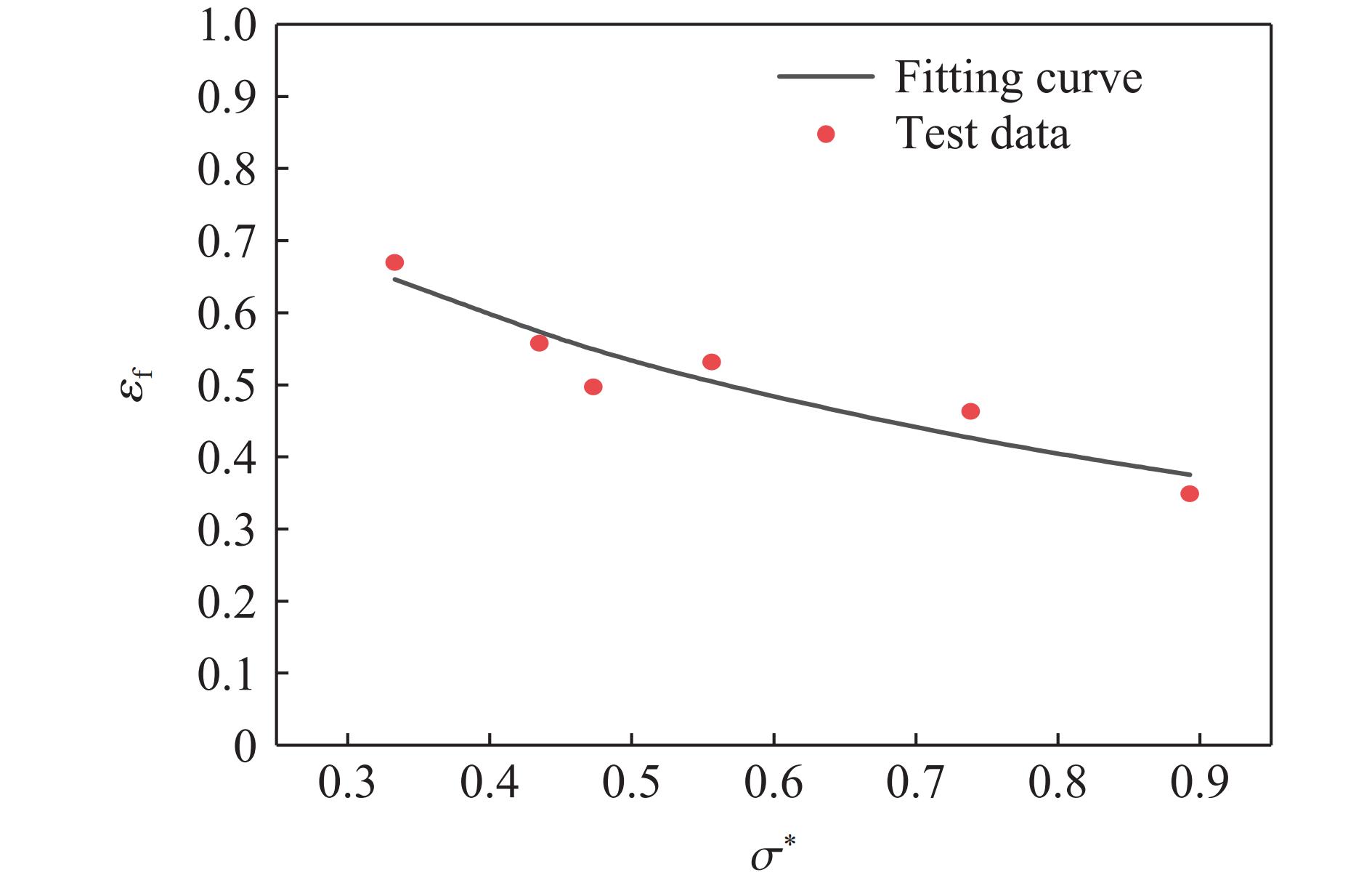

Table 2. Failure strain of notch specimens under different notch radii

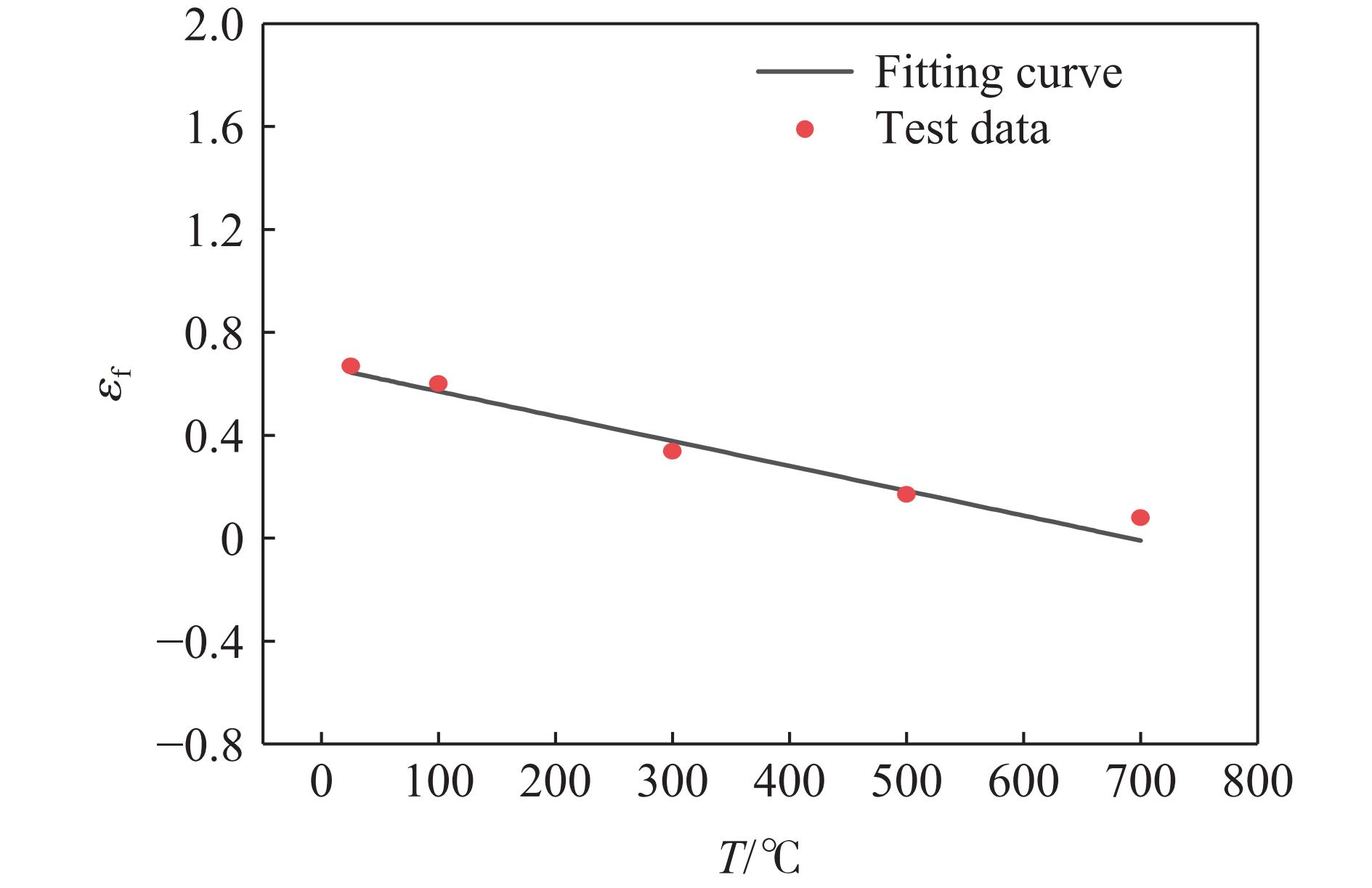

试件编号 σ* εf 2-1 0.89 0.35 2-2 0.74 0.46 2-3 0.56 0.53 2-4 0.47 0.50 2-5 0.43 0.55 2-6 0.33 0.67 表 3 高温拉伸试验中光滑圆棒试件的失效应变

Table 3. Failure strain of smooth round bar specimens in high temperature tensile test

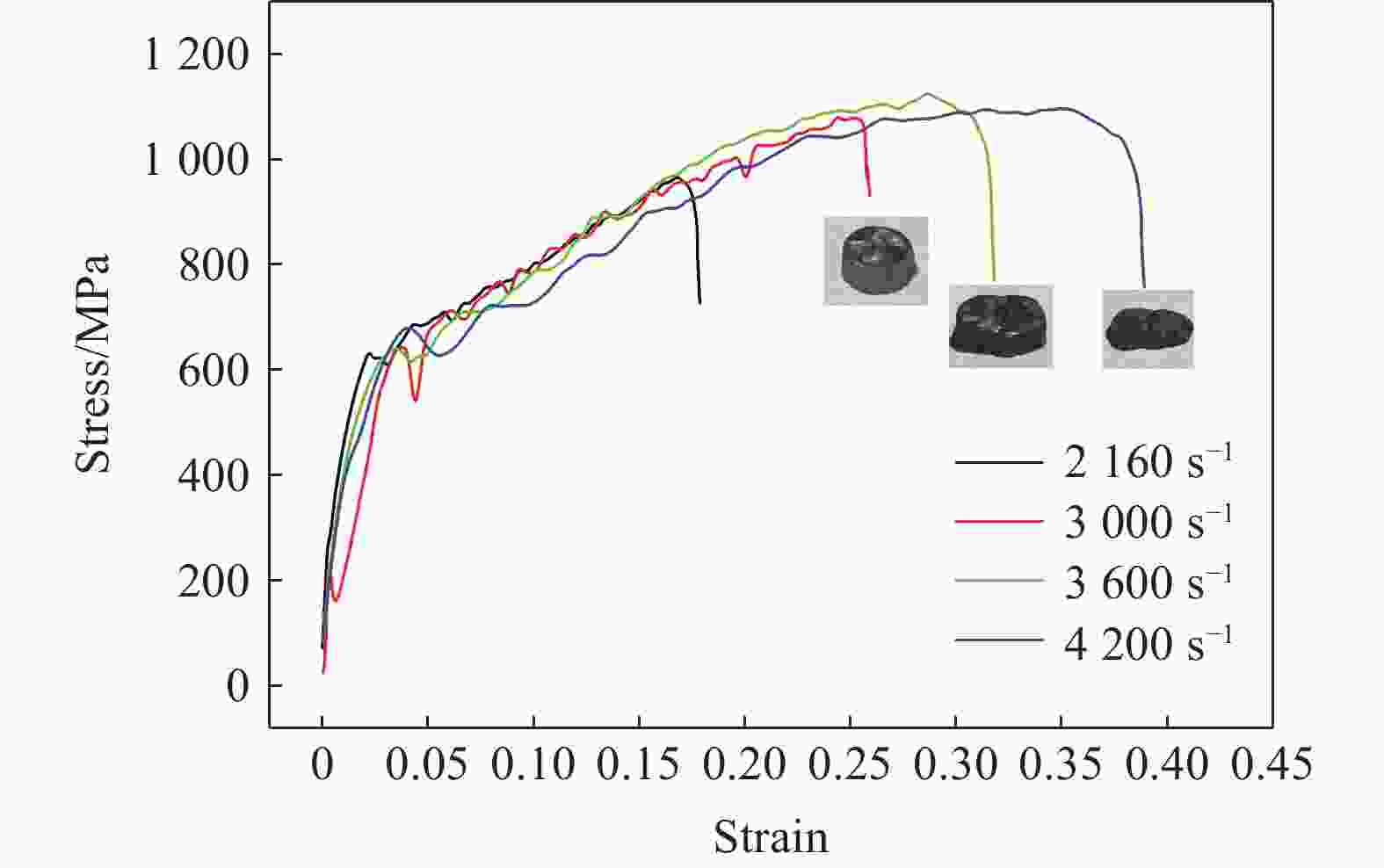

试件编号 温度/℃ εf 3-1 100 0.60 3-2 300 0.34 3-3 500 0.17 3-4 700 0.08 表 4 不同应变率下高熵合金的屈服强度

Table 4. HEA yield stress under different strain rates

应变率/s−1 屈服强度/MPa 2160 639.1 3000 648.4 3600 650.8 4200 679.0 表 5 不同温度条件下高熵合金的屈服强度

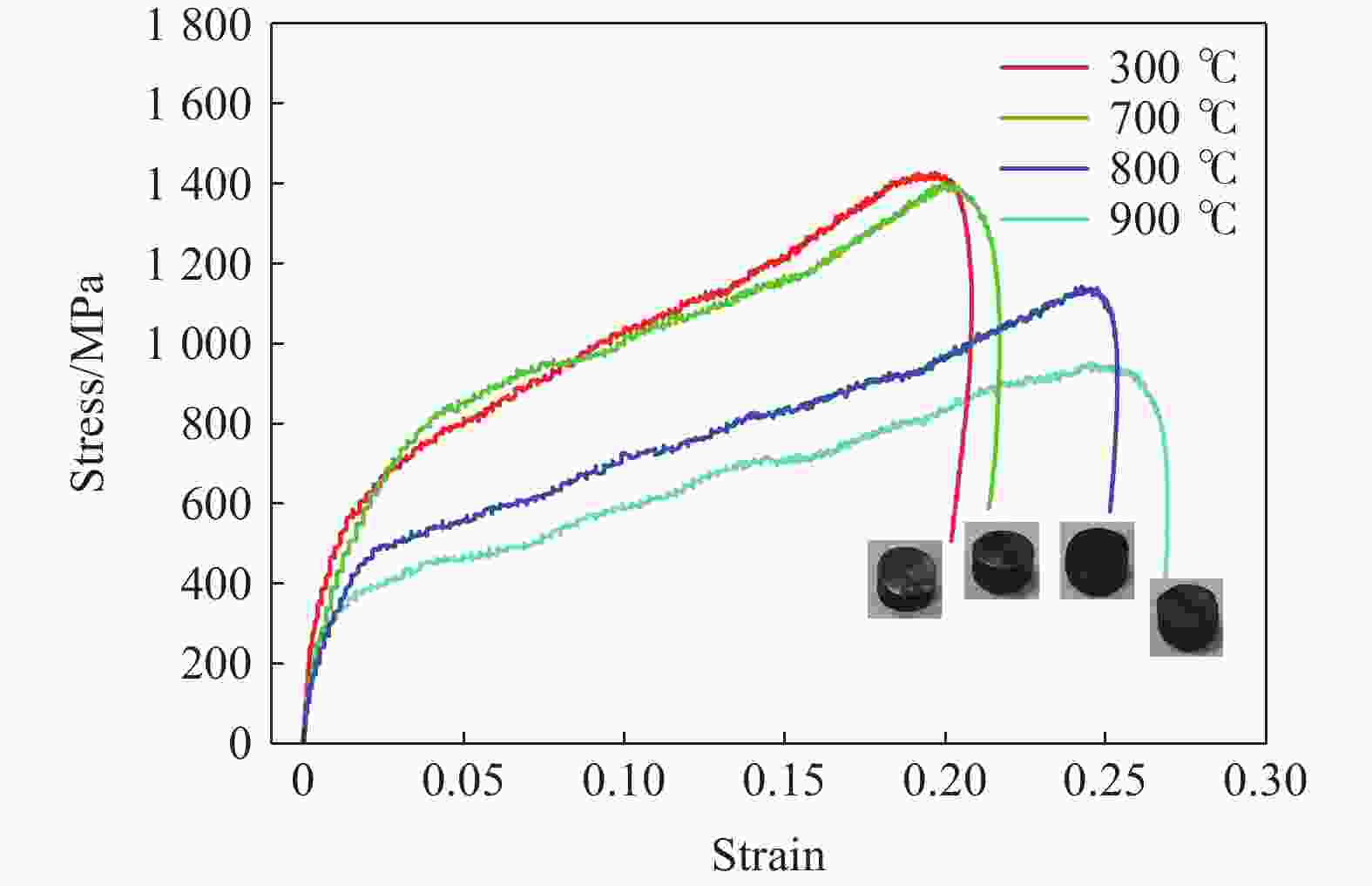

Table 5. Variation of yield strength of HEA under different temperatures

温度/℃ 屈服强度/MPa 300 353.7 700 295.3 800 248.9 900 233.7 表 7 药型罩材料的J-C本构方程参数

Table 7. J-C constitutive equation parameters for liner materials

A/MPa B/MPa n C m 270.2 571.3 0.79 0.062 0.638 表 6 药型罩材料的Grüneisen状态方程参数[5]

Table 6. Grüneisen state equation parameters for liner materials

ρ/(g·cm−3) γ C0/(m·s−1) S 11.7 1.1147 3213.0 1.1218 表 8 药型罩材料的J-C失效方程参数

Table 8. J-C failure equation parameters for liner materials

D1 D2 D3 D4 D5 0.24 0.78 −1.98 0.076 −3.269 -

[1] 李天昕, 王书道, 卢一平, 等. 高熵合金材料研究进展与展望 [J]. 中国工程科学, 2023, 25(3): 170–181. DOI: 10.15302/J-SSCAE-2023.03.016.LI T X, WANG S D, LU Y P, et al. Research progress and prospect of high-entropy alloy materials [J]. Strategic Study of CAE, 2023, 25(3): 170–181. DOI: 10.15302/J-SSCAE-2023.03.016. [2] 王先珍, 王一涵, 俞嘉彬, 等. 高熵合金性能特点与应用展望 [J]. 精密成形工程, 2022, 14(11): 73–80. DOI: 10.3969/j.issn.1674-6457.2022.11.008.WANG X Z, WANG Y H, YU J B, et al. A brief review about perspective and properties of high-entropy alloys [J]. Journal of Netshape Forming Engineering, 2022, 14(11): 73–80. DOI: 10.3969/j.issn.1674-6457.2022.11.008. [3] 张周然. HfZrTiTax高熵合金含能结构材料的组织结构与力学性能研究 [D]. 长沙: 国防科学技术大学, 2017: 86–87. DOI: 10.27052/d.cnki.gzjgu.2017.000221.ZHANG Z R. Microstructure and mechanical properties of HfZrTiTax high-entropy alloys energetic structural materials [D]. Changsha: National University of Defense Technology, 2017: 86–87. DOI: 10.27052/d.cnki.gzjgu.2017.000221. [4] LIU X F, TIAN Z L, ZHANG X F, et al. “Self-sharpening” tungsten high-entropy alloy [J]. Acta Materialia, 2020, 186: 257–266. DOI: 10.1016/j.actamat.2020.01.005. [5] 陈海华, 张先锋, 赵文杰, 等. W25Fe25Ni25Mo25高熵合金高速侵彻细观结构演化特性 [J]. 力学学报, 2022, 54(8): 2140–2151. DOI: 10.6052/0459-1879-22-128.CHEN H H, ZHANG X F, ZHAO W J, et al. Effect of microstructure on flow behavior during penetration of W25Fe25Ni25Mo25 high-entropy alloy projectile [J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(8): 2140–2151. DOI: 10.6052/0459-1879-22-128. [6] 鄢阿敏, 乔禹, 戴兰宏. 高熵合金药型罩射流成型与稳定性 [J]. 力学学报, 2022, 54(8): 2119–2130. DOI: 10.6052/0459-1879-22-274.YAN A M, QIAO Y, DAI L H. Formation and stability of shaped charge liner jet of CrMnFeCoNi high-entropy alloy [J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(8): 2119–2130. DOI: 10.6052/0459-1879-22-274. [7] 马田, 吕永柱, 张博, 等. TiZrNbVAl高熵合金弹体侵彻双层钢板可行性研究 [J]. 兵器装备工程学报, 2023, 44(11): 23–28. DOI: 10.11809/bqzbgcxb2023.11.003.MA T, LYU Y Z, ZHANG B, et al. Feasibility study on TiZrNbVAl high-entropy alloy projectile penetrating double layer steel plates [J]. Journal of Ordnance Equipment Engineering, 2023, 44(11): 23–28. DOI: 10.11809/bqzbgcxb2023.11.003. [8] 马胜国, 王志华. CoCrFeNiAl x系高熵合金的动态力学性能和本构关系 [J]. 爆炸与冲击, 2021, 41(11): 111101. DOI: 10.11883/bzycj-2020-0293.MA S G, WANG Z H. Dynamic mechanical properties and constitutive relations of CoCrFeNiAl x high entropy alloys [J]. Explosion and Shock Waves, 2021, 41(11): 111101. DOI: 10.11883/bzycj-2020-0293. [9] LI Z, ZHAO S, DIAO H, et al. High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: remarkable resistance to shear failure [J]. Scientific Reports, 2017, 7(1): 42742. DOI: 10.1038/srep42742. [10] 陈嘉琳, 李述涛, 陈叶青. 考虑晶体取向的Al0.3CoCrFeNi高熵合金动态力学性能研究 [J]. 爆炸与冲击, 2024, 44(3): 031401. DOI: 10.11883/bzycj-2023-0324.CHEN J L, LI S T, CHEN Y Q. A study on dynamic mechanical properties of Al0.3CoCrFeNi high-entropy alloy considering crystal orientation [J]. Explosion and Shock Waves, 2024, 44(3): 031401. DOI: 10.11883/bzycj-2023-0324. [11] 蒋文灿, 程祥珍, 梁斌, 等. 一种组合药型罩聚能装药战斗部对含水复合结构毁伤的数值模拟及试验研究 [J]. 爆炸与冲击, 2022, 42(8): 083303. DOI: 10.11883/bzycj-2021-0389.JIANG W C, CHENG X Z, LIANG B, et al. Numerical simulation and experimental study on the damage of water partitioned structure by a shaped charge warhead with a combined charge liner [J]. Explosion and Shock Waves, 2022, 42(8): 083303. DOI: 10.11883/bzycj-2021-0389. [12] 付恒, 蒋建伟, 王树有, 等. 爆炸成型弹丸药型罩用高密度合金选取准则 [J]. 兵工学报, 2022, 43(9): 2330–2338. DOI: 10.12382/bgxb.2021.0826.FU H, JIANG J W, WANG S Y, et al. High-density alloy selection criteria for liners of explosively formed projectiles [J]. Acta Armamentarii, 2022, 43(9): 2330–2338. DOI: 10.12382/bgxb.2021.0826. [13] 门建兵, 卢易浩, 蒋建伟, 等. 杆式EFP用钽钨合金JC失效模型参数 [J]. 高压物理学报, 2020, 34(6): 065105. DOI: 10.11858/gywlxb.20200550.MEN J B, LU Y H, JIANG J W, et al. Johnson-cook failure model parameters of tantalum-tungsten alloy for rod-shaped EFP [J]. Chinese Journal of High Pressure Physics, 2020, 34(6): 065105. DOI: 10.11858/gywlxb.20200550. [14] 陈刚, 陈忠富, 徐伟芳, 等. 45钢的J-C损伤失效参量研究 [J]. 爆炸与冲击, 2007, 27(2): 131–135. DOI: 10.11883/1001-1455(2007)02-0131-05.CHEN G, CHEN Z F, XU W F, et al. Investigation on the J-C ductile fracture parameters of 45 steel [J]. Explosion and Shock Waves, 2007, 27(2): 131–135. DOI: 10.11883/1001-1455(2007)02-0131-05. [15] 门建兵, 蒋建伟, 王树有. 爆炸冲击数值模拟技术基础 [M]. 北京: 北京理工大学出版社, 2015: 146–147.MEN J B, JIANG J W, WANG S Y. Foundation of numerical simulation for explosion and shock problems [M]. Beijing: Beijing Institute of Technology Press, 2015: 146–147. [16] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures [J]. Engineering Fracture Mechanics, 1985, 21(1): 31–48. DOI: 10.1016/0013-7944(85)90052-9. [17] 朱志鹏, 门建兵, 蒋建伟, 等. 大长径比钽爆炸成型弹丸控制研究 [J]. 兵工学报, 2018, 39(S1): 29–36. DOI: 10.3969/j.issn.1000-1093.2018.S1.005.ZHU Z P, MEN J B, JIANG J W, et al. Forming control of tantalum EFP with large aspect ratio [J]. Acta Armamentarii, 2018, 39(S1): 29–36. DOI: 10.3969/j.issn.1000-1093.2018.S1.005. [18] 陈刚, 陈忠富, 陶俊林, 等. 45钢动态塑性本构参量与验证 [J]. 爆炸与冲击, 2005, 25(5): 451–456. DOI: 10.11883/1001-1455(2005)05-0451-06.CHEN G, CHEN Z F, TAO J L, et al. Investigation and validation on plastic constitutive parameters of 45 steel [J]. Explosion and Shock Waves, 2005, 25(5): 451–456. DOI: 10.11883/1001-1455(2005)05-0451-06. [19] 彭嘉诚. 后效增强自旋式EFP技术研究 [D]. 北京: 北京理工大学, 2022: 98–99.PENG J C. Research on technologies of spin-up EFP with enhanced aftereffects [D]. Beijing: Beijing Institute of Technology, 2022: 98–99. [20] 辛春亮, 薛再清, 涂建, 等. 有限元分析常用材料参数手册 [M]. 北京: 机械工业出版社, 2019: 109. [21] 徐恒威, 梁斌, 刘俊新, 等. 药型罩形位偏差对聚能装药射流成型及其破甲过程影响 [J]. 含能材料, 2023, 31(10): 1049–1058. DOI: 10.11943/CJEM2022292.XU H W, LIANG B, LIU J X, et al. Influence of shape and position deviation of liner on jet forming and penetration process of shaped charge [J]. Chinese Journal of Energetic Materials, 2023, 31(10): 1049–1058. DOI: 10.11943/CJEM2022292. -

下载:

下载: