Response of CL-20-based high-detonation-velocity pressed explosive to drop-hammer impact

-

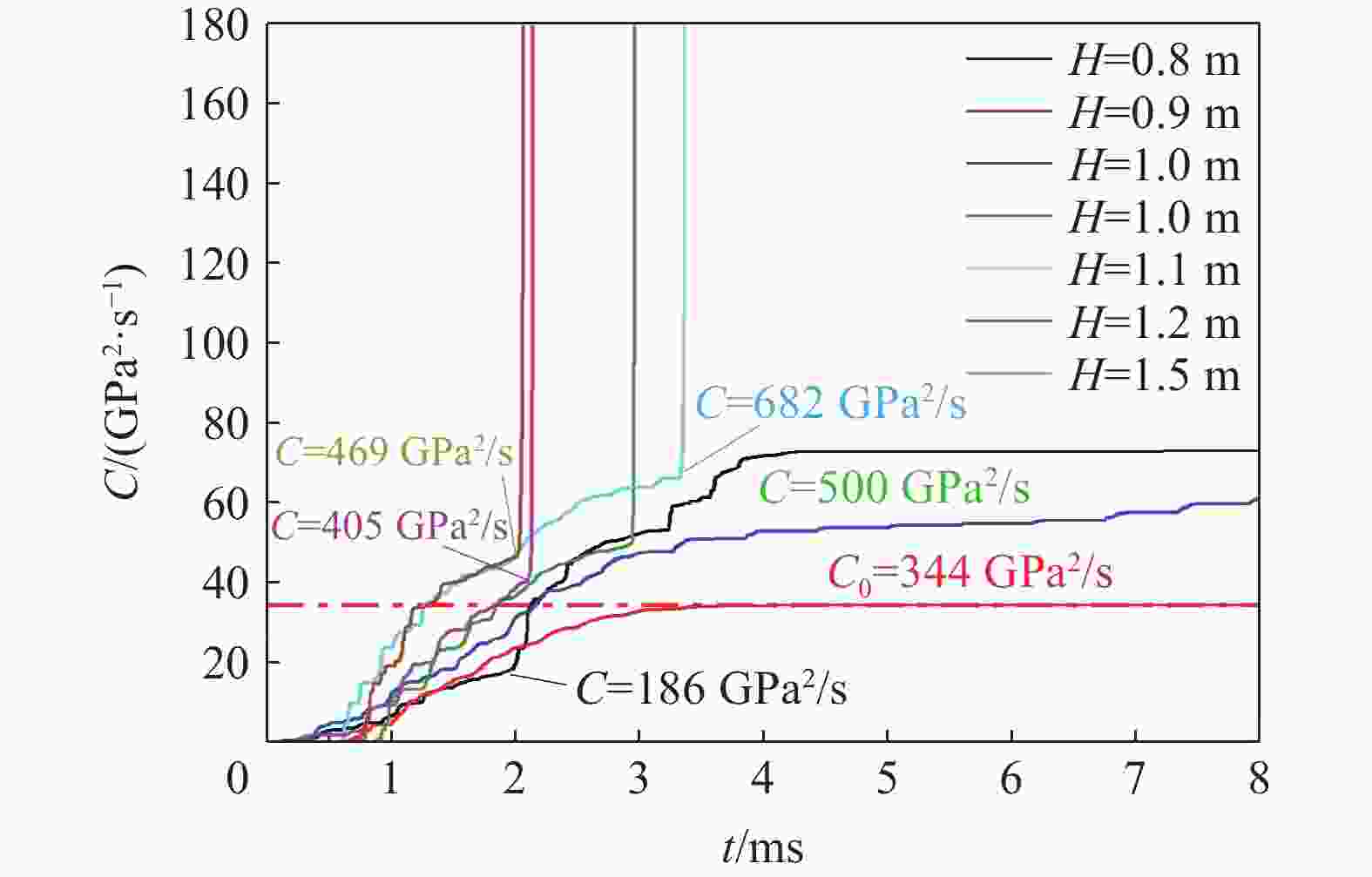

摘要: 针对典型CL-20基高爆速压装炸药(C-1, 94.5% CL-20+5.5%助剂)的发射安全性问题,开展了400 kg大型落锤试验对压装炸药C-1的冲击响应特性进行研究。同时,采用改进的应力率表征法及下限值法、特性落高法分别对该炸药的落锤冲击响应特性进行表征,并与同类压装炸药JO-8和JH-2进行了对比。得到了不同落高下3种压装炸药底部实测应力曲线及表征参数,并讨论了3种炸药撞击感度的差异及C-1炸药撞击感度的影响因素。结果表明,改进的应力率表征法对炸药撞击感度的表征具有一定的有效性和普适性,与其他方法对撞击感度规律的反映具有一致性。C-1炸药的特性落高(H50)为1 m,分别为JO-8和JH-2炸药特性落高的62.50%和50.00%;C-1炸药不发生爆轰对应的后坐应力峰值(σ0)为748.90 MPa,分别为JO-8和JH-2的85.42%和64.33%;C-1的安全应力率参数(C0)为344 GPa2/s,分别为JO-8和JH-2的45.87%和39.14%。CL-20的分子结构、C-1药柱的力学性能和热-化特性是造成其撞击感度高于JO-8和JH-2撞击感度的主要因素。Abstract: For the launch safety problem of the typical CL-20-based high detonation velocity pressed explosive (C-1, 94.5% CL-20+5.5% additive), the impact response characteristics of the explosive were studied by a large-scale hammer test with 400 kg, which has an impact loading curve similar to the loading characteristics of artillery chamber pressure. Meanwhile, the improved stress rate characterization method, the lower limit method, and the drop height method were used to characterize the drop hammer impact response characteristics of the explosive, and compared with the same kind of pressed explosives JO-8 and JH-2. The improved stress rate characterization method is obtained by improving the data processing process based on existing criteria and weakening the sensitivity of the original criterion formula to oscillatory waveforms. The measured stress curves and characterization parameters of the bottom of the three pressed explosives under different drop heights are obtained by tests, and the impact sensitivity differences of the explosives and influence factors of the impact sensitivity of C-1 are discussed. The results show that the improved stress rate characterization method has certain effectiveness and universality for characterizing the impact sensitivity of explosives. Meanwhile, the improved stress rate characterization method is consistent with other methods in reflecting the law. The drop height of C-1 (H50) is 1.0 m, which is 62.50% and 50.00% of JO-8 and JH-2, respectively; the peak stress of the backseat corresponding to non-detonation (σ0) is 748.90 MPa, which is 85.42% and 64.33% of JO-8 and JH-2, respectively; the safety stress rate parameter (C0) is 344 GPa2/s, which is 45.87% and 39.14% of JO-8 and JH-2, respectively. The molecular structure of CL-20, the mechanical properties, and the thermal-chemical characteristics of the C-1 explosive cylinder are the main factors that make its impact sensitivity higher than JO-8 and JH-2. The research results can provide a reference for the application and design calculation of CL-20-based high detonation velocity pressed explosives in a high overload environment.

-

表 1 不同落高落锤试验结果

Table 1. Results of drop-hammer tests at different heights

落高/m 爆轰概率/% 落高/m 爆轰概率/% 0.8 0 1.1 100 0.9 0 1.2 100 1.0 50 1.5 100 表 2 C-1炸药冲击响应特性表征

Table 2. Impact response characterization of explosive C-1

特性落高法 下限值法 应力率表征法 H50/m σ50/MPa H0/m σ0/MPa C0/(GPa2·s−1) 1.0 776.79 0.9 748.90 344 -

[1] 彭翠枝, 赵春柳, 毛长勇, 等. 国外CL-20炸药技术发展分析 [J]. 火炸药学报, 2022, 45(3): 290–299. DOI: 10.14077/j.issn.1007-7812.202203003.PENG C Z, ZHAO C L, MAO C Y, et al. Foreign development status of CL-20 explosive technology [J]. Chinese Journal of Explosives & Propellants, 2022, 45(3): 290–299. DOI: 10.14077/j.issn.1007-7812.202203003. [2] PARAKHIN V V, SMIRNOV G A. Research progress on design, synthesis and performance of energetic polynitro hexaazaisowurtzitane derivatives: towards improved CL-20 analogues [J]. FirePhysChem, 2024, 4(1): 21–33. DOI: 10.1016/j.fpc.2023.05.006. [3] BARI R, DENTON A A, FONDREN Z T, et al. Acceleration of decomposition of CL-20 explosive under nanoconfinement [J]. Journal of Thermal Analysis and Calorimetry, 2020, 140(6): 2649–2655. DOI: 10.1007/s10973-019-09027-5. [4] YANG L F, SHI X R, LI C Z, et al. Microfluidic assisted 90% loading CL-20 spherical particles: enhancing self-sustaining combustion performance [J]. Defence Technology, 2023, 22: 176–184. DOI: 10.1016/j.dt.2021.12.004. [5] 吴成成, 王正宏, 李世伟, 等. CL-20基压装炸药结构成型载体的设计及其应用 [J]. 火炸药学报, 2022, 45(3): 388–395. DOI: 10.14077/j.issn.1007-7812.202204020.WU C C, WANG Z H, LI S W, et al. Design and application of CL-20-based pressed explosives structure forming carrier [J]. Chinese Journal of Explosives & Propellants, 2022, 45(3): 388–395. DOI: 10.14077/j.issn.1007-7812.202204020. [6] 刘正, 聂建新, 徐星, 等. 密闭空间内六硝基六氮杂异伍兹烷基复合炸药能量释放特性 [J]. 兵工学报, 2022, 43(3): 503–512. DOI: 10.12382/bgxb.2021.0163.LIU Z, NIE J X, XU X, et al. Energy release characteristics of CL-20-based composite explosives in confined space [J]. Acta Armamentarii, 2022, 43(3): 503–512. DOI: 10.12382/bgxb.2021.0163. [7] GAO H X, ZHANG Q H, SHREEVE J M. Fused heterocycle-based energetic materials (2012—2019) [J]. Journal of Materials Chemistry A, 2020, 8(8): 4193–4216. DOI: 10.1039/c9ta12704f. [8] LI C Y, KONG S, LIAO D J, et al. Fabrication and characterization of mussel-inspired layer-by-layer assembled CL-20-based energetic films via micro-jet printing [J]. Defence Technology, 2022, 18(10): 1748–1759. DOI: 10.1016/j.dt.2021.12.001. [9] 阚润哲, 聂建新, 郭学永, 等. 不同铝氧比CL-20基含铝炸药深水爆炸能量输出特性 [J]. 兵工学报, 2022, 43(5): 1023–1031. DOI: 10.12382/bgxb.2021.0227.KAN R Z, NIE J X, GUO X Y, et al. Energy output characteristics of CL-20-based aluminized explosives with different Al/O ratios during deep-water explosion [J]. Acta Armamentarii, 2022, 43(5): 1023–1031. DOI: 10.12382/bgxb.2021.0227. [10] 吕中杰, 高晨宇, 赵开元, 等. 铝质量分数对CL-20基炸药驱动筒壁能量输出结构影响 [J]. 北京理工大学学报, 2023, 43(1): 27–35. DOI: 10.15918/j.tbit1001-0645.2022.015.LÜ Z J, GAO C Y, ZHAO K Y, et al. Influence of aluminum content on energy output structure of CL-20-based explosives driving cylinder wall [J]. Transactions of Beijing Institute of Technology, 2023, 43(1): 27–35. DOI: 10.15918/j.tbit1001-0645.2022.015. [11] SONG S W, TIAN X L, WANG Y, et al. Theoretical insight into density and stability differences of RDX, HMX and CL-20 [J]. CrystEngComm, 2022, 24(8): 1537–1545. DOI: 10.1039/d1ce01577j. [12] SHA Y, ZHANG X B. Reaction mechanism of hydrogen peroxide enhancing detonation performance in the host-guest structure of CL-20 by reactive molecular dynamics simulations [J]. Vacuum, 2023, 211: 111929. DOI: 10.1016/j.vacuum.2023.111929. [13] MAO X X, JIANG L F, LI Y F, et al. Preparation of sub-micron sized CL-20 and its mechanical and thermal properties [J]. Propellants, Explosives, Pyrotechnics, 2021, 46(1): 52–60. DOI: 10.1002/prep.202000137. [14] GAO F B, JING J Q, CHENG W J, et al. Molecular dynamics simulation of bilayer core-shell structure of CL-20 surface-modified by polydopamine coated with polymer binder [J]. Materials Today Communications, 2023, 37: 107099. DOI: 10.1016/j.mtcomm.2023.107099. [15] HE W J, LI Y N, BAO P, et al. Utilizing surface modification in coating technology to enhance the efficiency of CL-20 desensitization [J]. FirePhysChem, 2024, 4(1): 72–79. DOI: 10.1016/j.fpc.2023.10.002. [16] ZHANG X P, CHEN S S, WU Y G, et al. A novel cocrystal composed of CL-20 and an energetic ionic salt [J]. Chemical Communications, 2018, 54(94): 13268–13270. DOI: 10.1039/c8cc06540c. [17] LIU K, ZHANG G, LUAN J Y, et al. Crystal structure, spectrum character and explosive property of a new cocrystal CL-20/DNT [J]. Journal of Molecular Structure, 2016, 1110: 91–96. DOI: 10.1016/j.molstruc.2016.01.027. [18] ANDERSON S R, DUBÉ P, KRAWIEC M, et al. Promising CL-20-based energetic material by cocrystallization [J]. Propellants, Explosives, Pyrotechnics, 2016, 41(5): 783–788. DOI: 10.1002/prep.201600065. [19] LIU N, DUAN B H, LU X M, et al. Preparation of CL-20/DNDAP cocrystals by a rapid and continuous spray drying method: an alternative to cocrystal formation [J]. CrystEngComm, 2018, 20(14): 2060–2067. DOI: 10.1039/C8CE00006A. [20] 王克强. 炸药破甲威力与爆轰参数之间定量关系的探讨 [J]. 火炸药学报, 1999, 18(2): 25–29. DOI: 10.3969/j.issn.1007-7812.1999.02.007.WANG K Q. Studies on the quantitative relation between the penetration performance and explosive properties [J]. Chinese Journal of Explosives & Propellants, 1999, 18(2): 25–29. DOI: 10.3969/j.issn.1007-7812.1999.02.007. [21] 南宇翔. 高能炸药爆炸驱动金属能量输出规律研究 [D]. 北京: 北京理工大学, 2015: 109–112.NAN Y X. Law of energy release for metal-driving by high-energy explosive [D]. Beijing: Beijing Institute of Technology, 2015: 109–112. [22] 王树有, 南宇翔, 蒋建伟, 等. 典型CL-20和HMX基压装炸药爆炸驱动特性对比 [J]. 含能材料, 2021, 29(4): 332–337. DOI: 10.11943/CJEM2020301.WANG S Y, NAN Y X, JIANG J W, et al. Comparative experimental study on explosion driving performance of typical CL-20 and HMX-based pressed explosives [J]. Chinese Journal of Energetic Materials, 2021, 29(4): 332–337. DOI: 10.11943/CJEM2020301. [23] 谈乐斌, 张相炎, 管红根, 等. 火炮概论 [M]. 北京: 北京理工大学出版社, 2005: 124–124.TAN L B, ZHANG X Y, GUAN H G, et al. Introduction to artillery [M]. Beijing: Beijing Institute of Technology Press, 2005: 124–124. [24] 皮铮迪. CL-20混合炸药冲击起爆特征及爆轰波成长规律研究 [D]. 北京: 北京理工大学, 2016.PI Z D. Investigate the shock into the detonation characteristics and rules of CL-20-based explosives [D]. Beijing: Beijing Institute of Technology, 2016. [25] 皮铮迪, 陈朗, 刘丹阳, 等. CL-20基混合炸药的冲击起爆特征 [J]. 爆炸与冲击, 2017, 37(6): 915–923. DOI: 10.11883/1001-1455(2017)06-0915-09.PI Z D, CHEN L, LIU D Y, et al. Shock initiation of CL-20 based explosives [J]. Explosion and Shock Waves, 2017, 37(6): 915–923. DOI: 10.11883/1001-1455(2017)06-0915-09. [26] 高家乐, 周霖, 苗飞超, 等. 过载环境下炸药装药点火过程的数值模拟 [J]. 火炸药学报, 2022, 45(3): 323–331. DOI: 10.14077/j.issn.1007-7812.202203031.GAO J L, ZHOU L, MIAO F C, et al. Numerical simulation of ignition process of explosive charge in overload environment [J]. Chinese Journal of Explosives & Propellants, 2022, 45(3): 323–331. DOI: 10.14077/j.issn.1007-7812.202203031. [27] 周霖, 倪磊, 李东伟, 等. 炸药抗过载性能试验方法 [J]. 兵工学报, 2023, 44(6): 1722–1732. DOI: 10.12382/bgxb.2022.0074.ZHOU L, NI L, LI D W, et al. Test method for anti-overload performance of explosives [J]. Acta Armamentarii, 2023, 44(6): 1722–1732. DOI: 10.12382/bgxb.2022.0074. [28] 王世英, 胡焕性. B炸药装药发射安全性落锤模拟加载实验研究 [J]. 爆炸与冲击, 2003, 23(3): 275–278. DOI: 10.11883/1001-1455(2003)03-0275-4.WANG S Y, HU H X. Drop hammer simulation study on launch safety of composite B [J]. Explosion and Shock Waves, 2003, 23(3): 275–278. DOI: 10.11883/1001-1455(2003)03-0275-4. [29] 高立龙, 牛余雷, 王浩, 等. 典型炸药柱的400 kg落锤撞击感度特性分析 [J]. 含能材料, 2011, 19(4): 428–431. DOI: 10.3969/j.issn.1006-9941.2011.04.017.GAO L L, NIU Y L, WANG H, et al. Analysis of impact sensitivity characteristics for typical explosive cylinder [J]. Chinese Journal of Energetic Materials, 2011, 19(4): 428–431. DOI: 10.3969/j.issn.1006-9941.2011.04.017. [30] 许志峰, 屈可朋. 装药发射安全性模拟加载实验方法研究 [J]. 火工品, 2015, 37(6): 51–53. DOI: 10.3969/j.issn.1003-1480.2015.06.014.XU Z F, QU K P. Study on experimental method of simulation loading for launch safety of charge [J]. Initiators & Pyrotechnics, 2015, 37(6): 51–53. DOI: 10.3969/j.issn.1003-1480.2015.06.014. [31] 黄正平, 张锦云, 张汉萍, 等. 后坐冲击模拟实验装置工作机理研究 [J]. 北京理工大学学报, 1994, 14(4): 371–377. DOI: 10.15918/j.tbit1001-0645.1994.04.008.HUANG Z P, ZHANG J Y, ZHANG H P, et al. Working principles of a setback-shock simulator [J]. Journal of Beijing Institute of Technology, 1994, 14(4): 371–377. DOI: 10.15918/j.tbit1001-0645.1994.04.008. [32] 刘海营, 张景林, 王作山. 炸药撞击感度的研究综述 [J]. 山西化工, 2007, 27(6): 57–59. DOI: 10.16525/j.cnki.cn14-1109/tq.2007.06.025.LIU H Y, ZHANG J L, WANG Z S. Study on the explosive impact sensitivity [J]. Shanxi Chemical Industry, 2007, 27(6): 57–59. DOI: 10.16525/j.cnki.cn14-1109/tq.2007.06.025. [33] TURCOTTE R, VACHON M, KWOK Q S M, et al. Thermal study of HNIW (CL-20) [J]. Thermochimica Acta, 2005, 433(1/2): 105–115. DOI: 10.1016/j.tca.2005.02.021. [34] 范夕萍, 王霞, 刘子如, 等. 纳米Cu粉对HMX和RDX热分解的催化作用 [J]. 含能材料, 2005, 13(5): 284–287. DOI: 10.3969/j.issn.1006-9941.2005.05.003.FAN X P, WANG X, LIU Z R, et al. Catalysis of nano Cu powder on the thermal decomposition of HMX and RDX [J]. Chinese Journal of Energetic Materials, 2005, 13(5): 284–287. DOI: 10.3969/j.issn.1006-9941.2005.05.003. -

下载:

下载: