Analysis on mechanical performance and damage evaluation of H-section steel columns during and after impact process

-

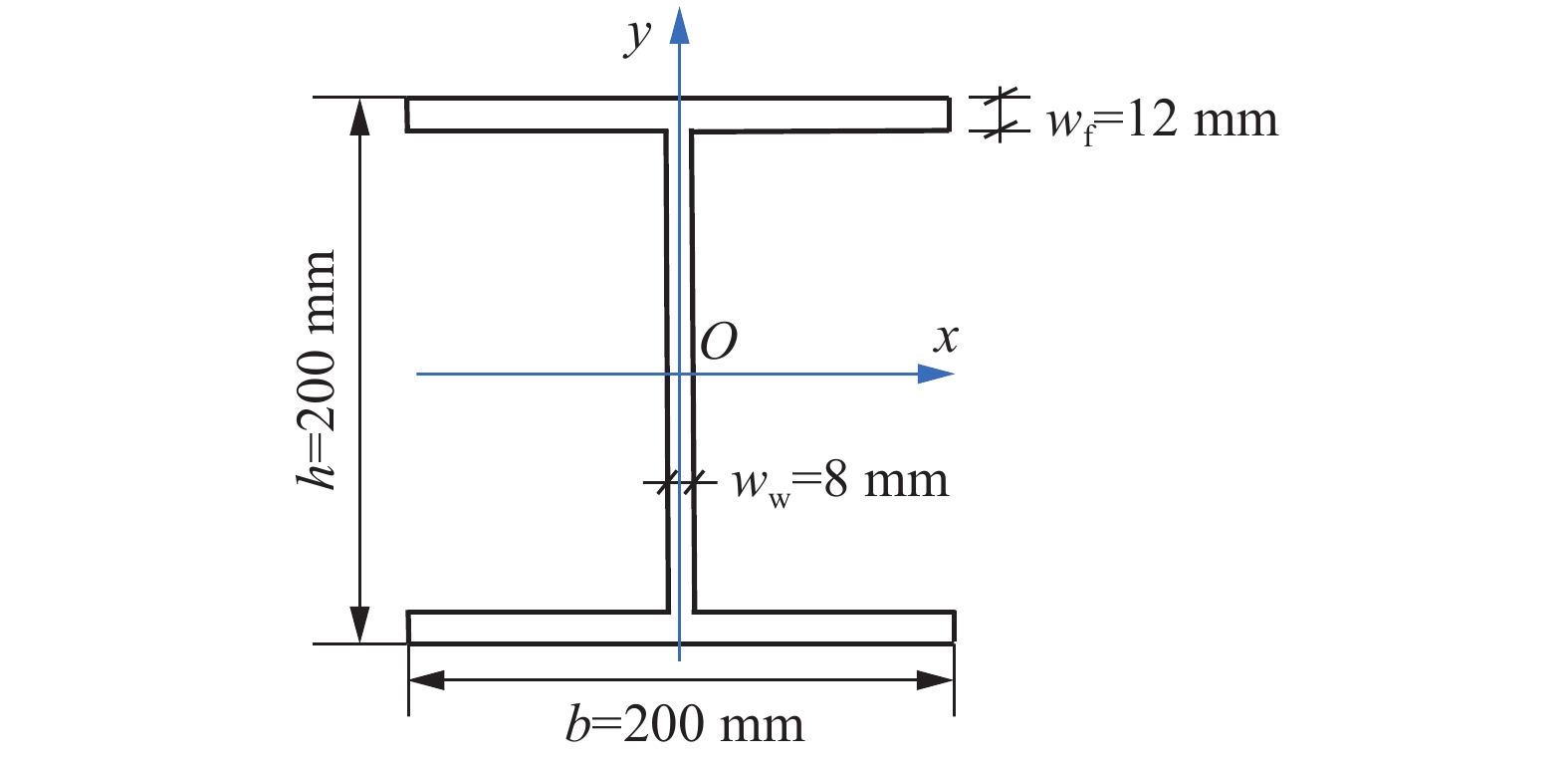

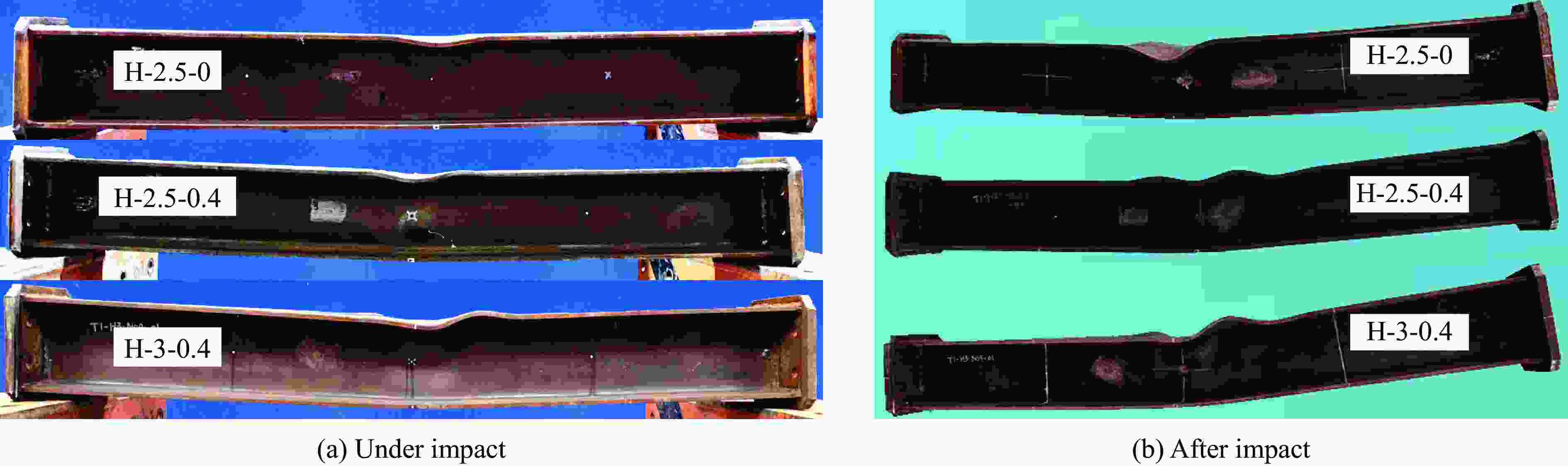

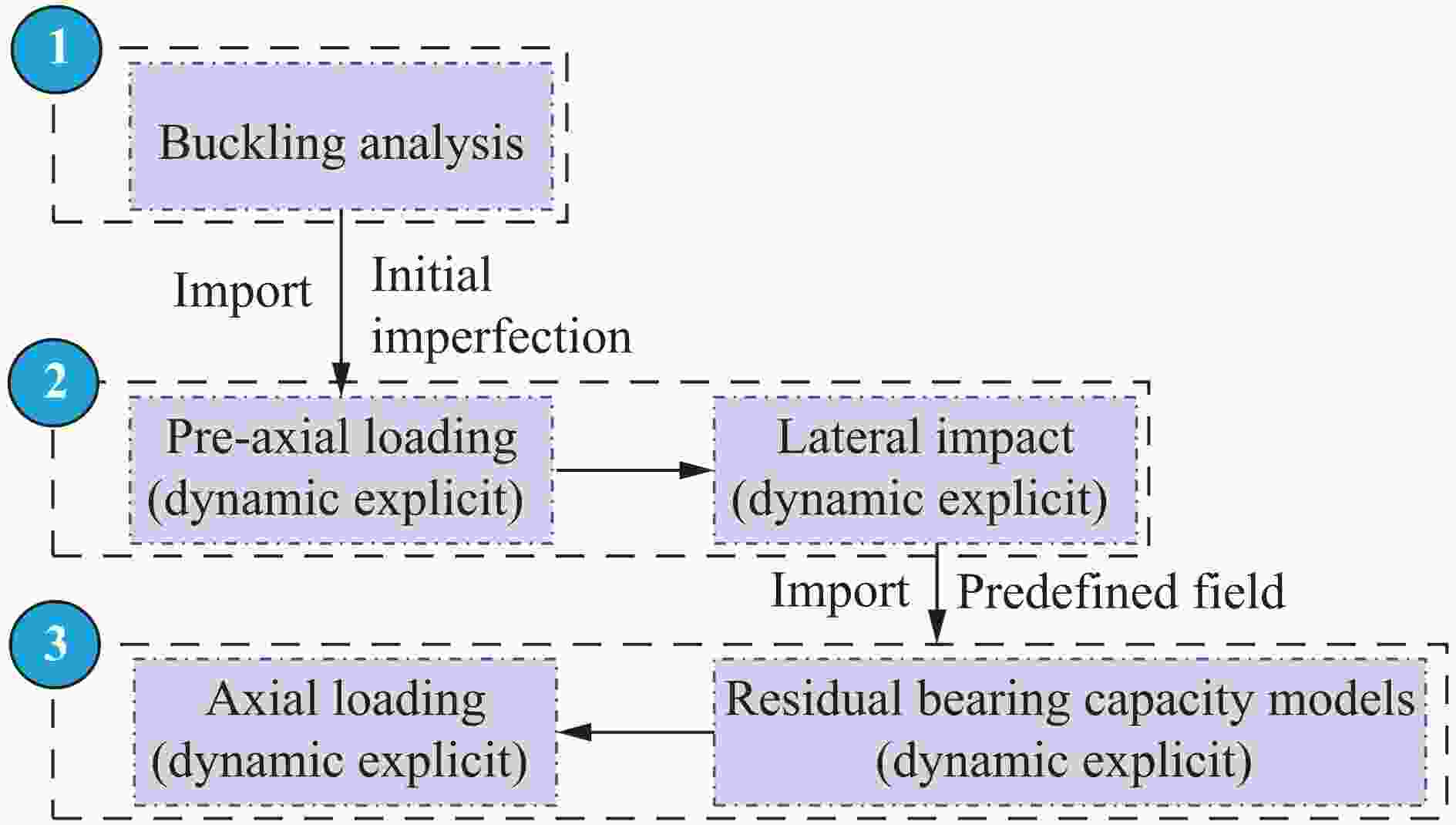

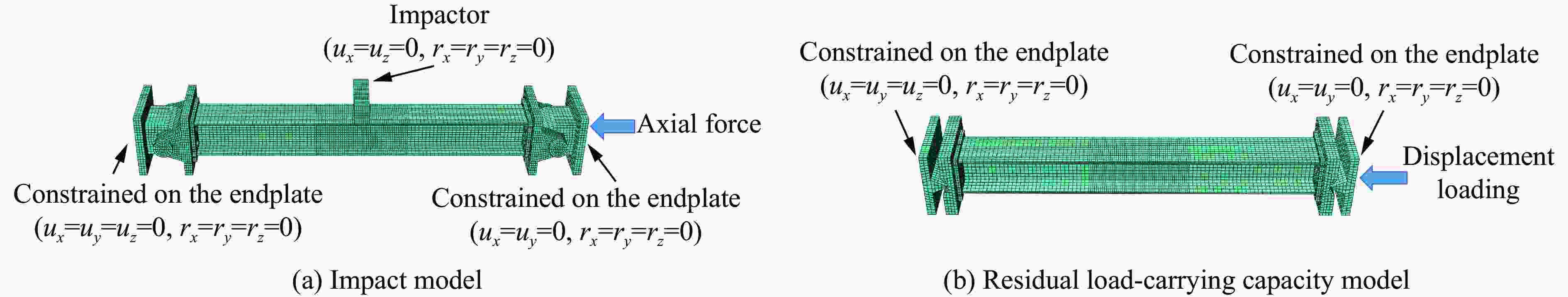

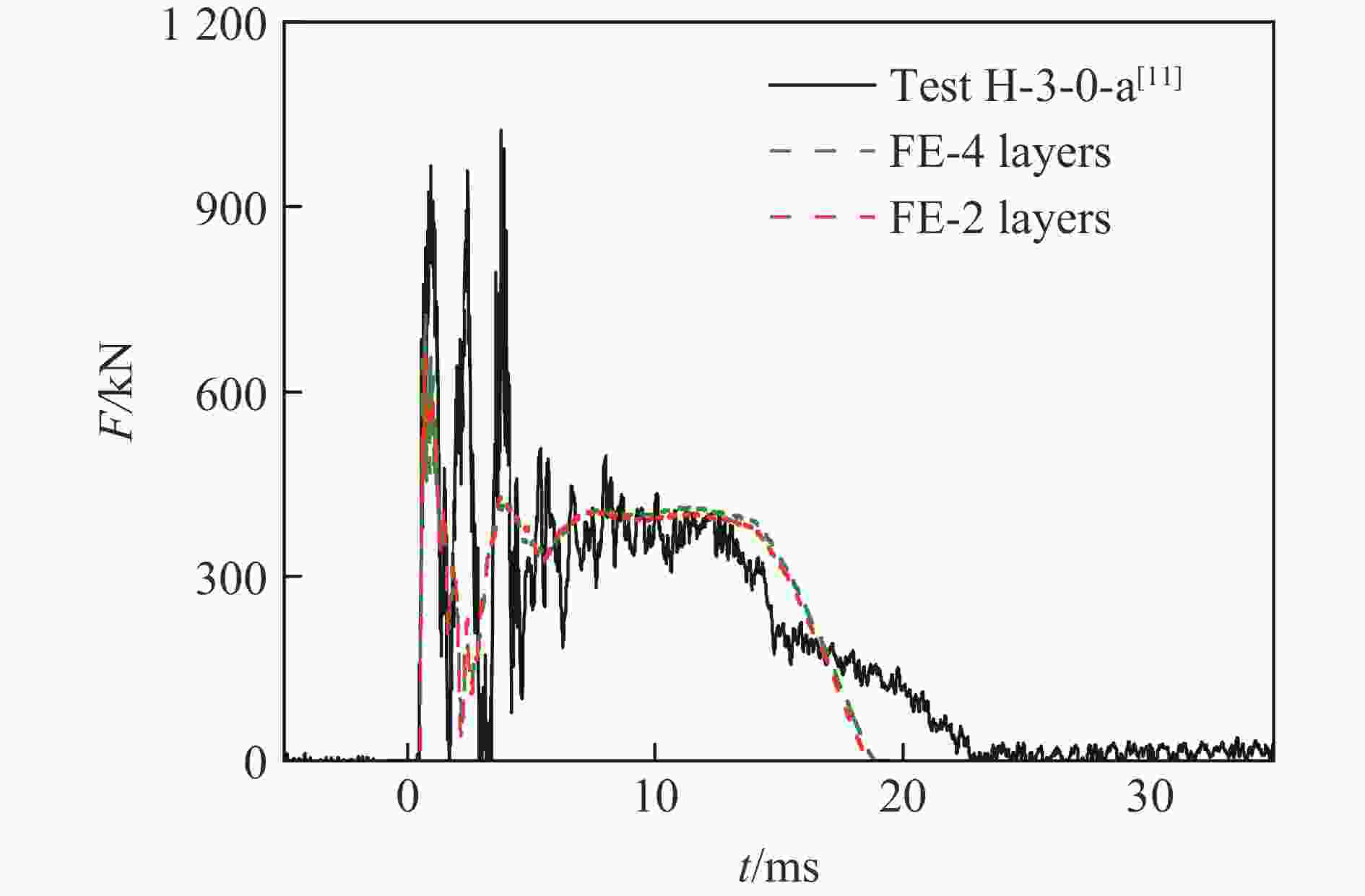

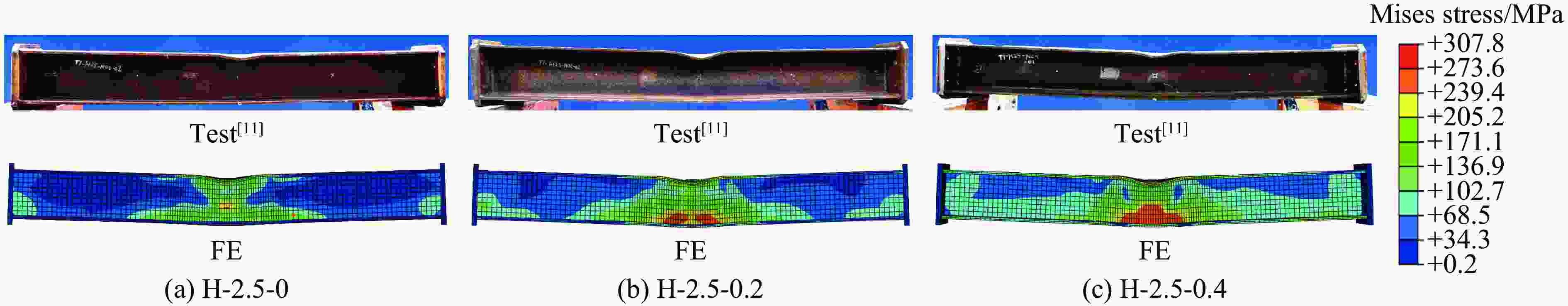

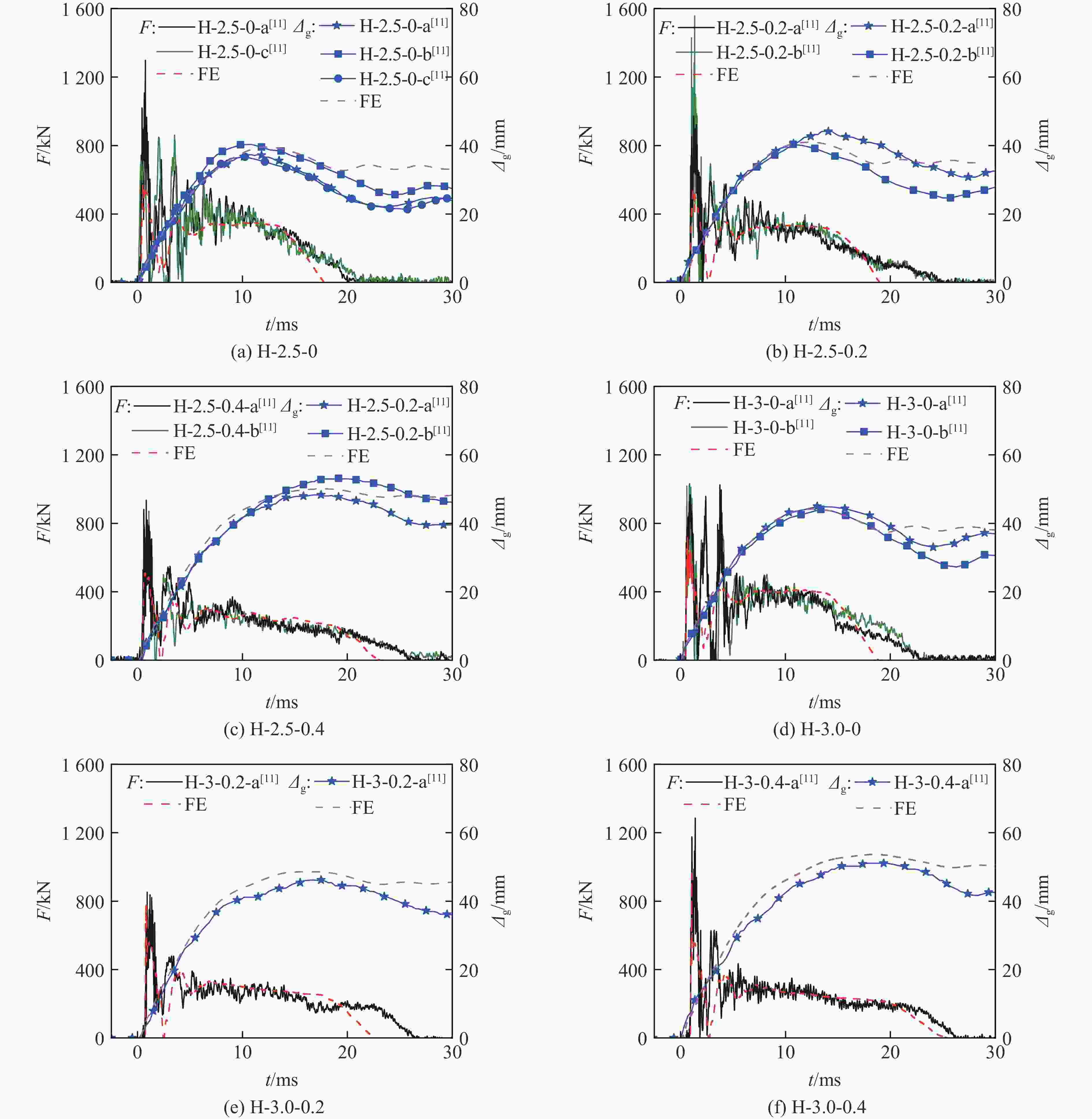

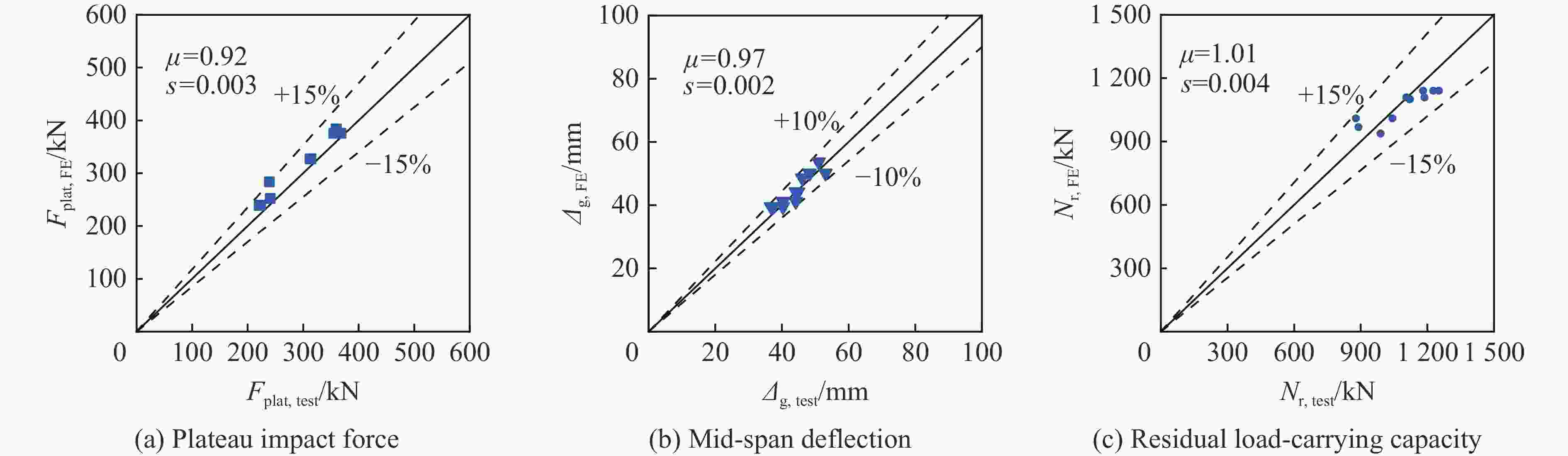

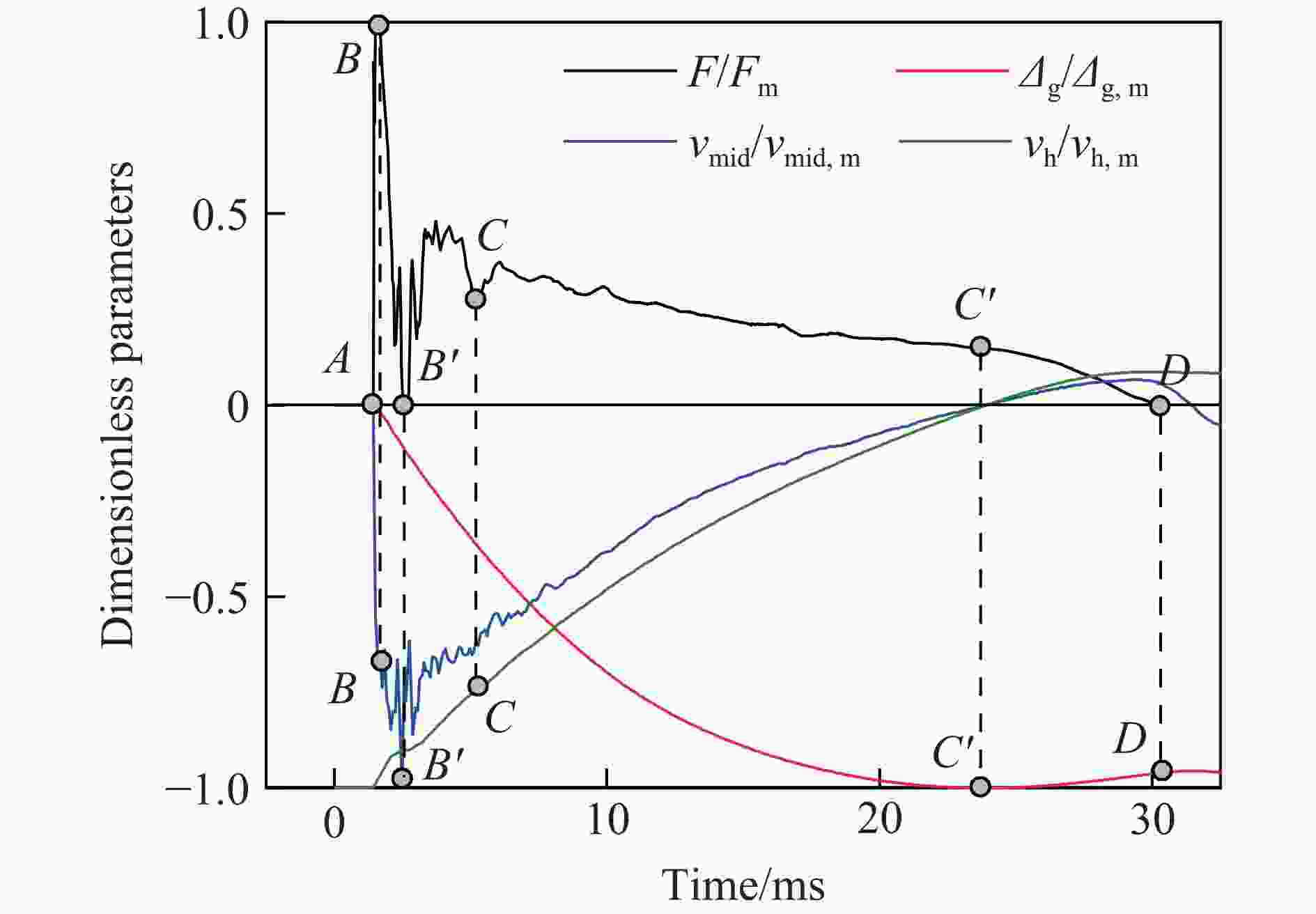

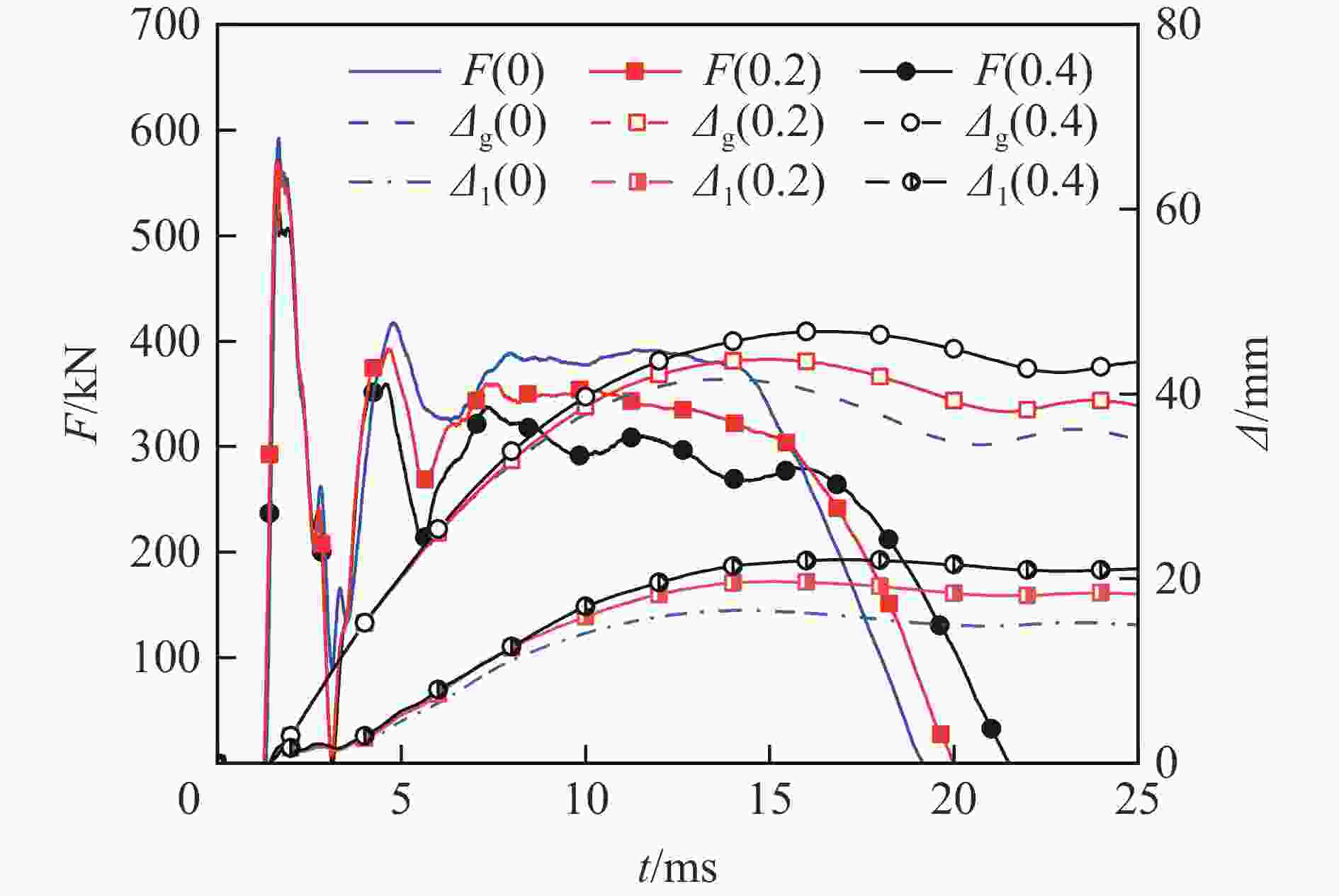

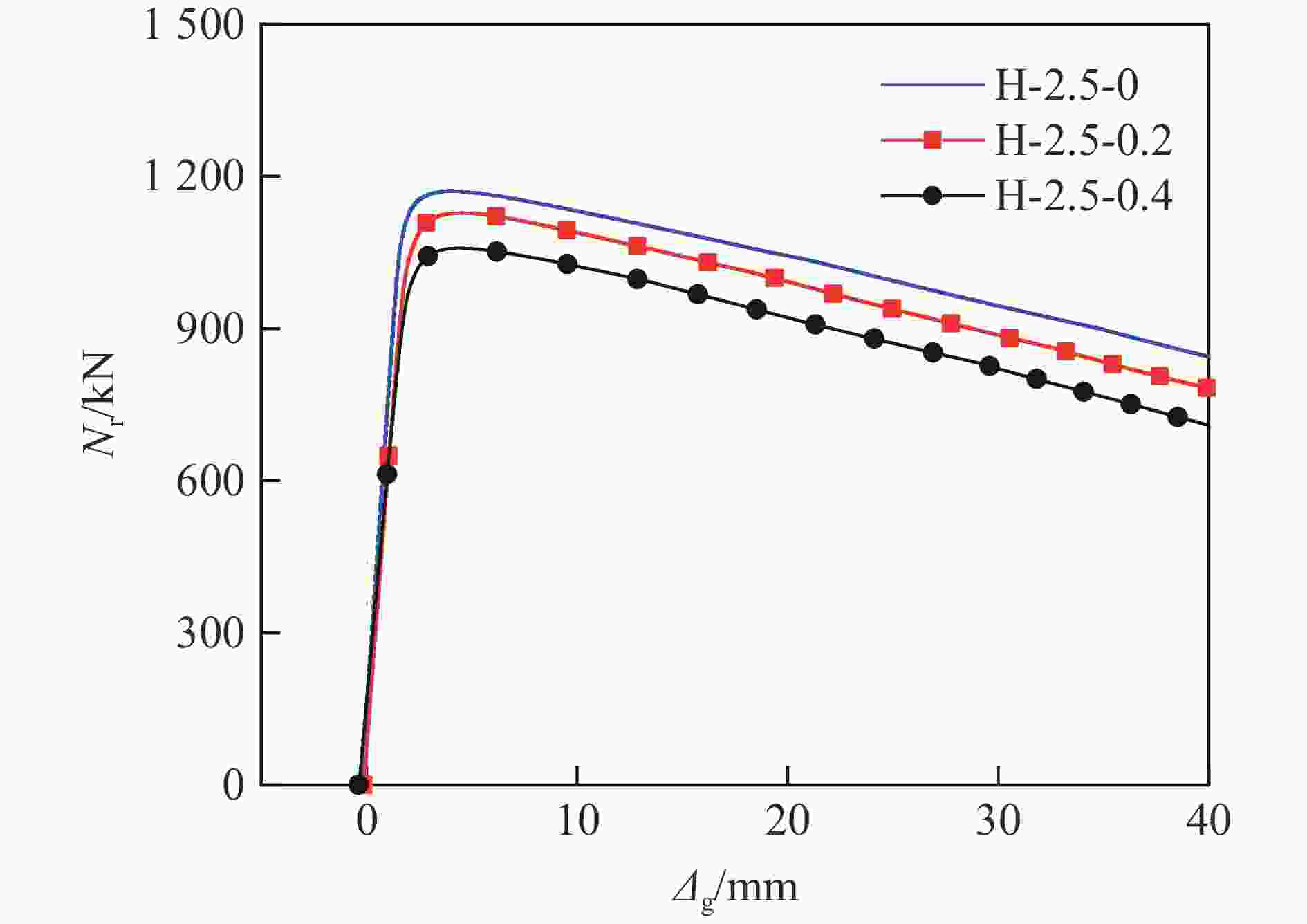

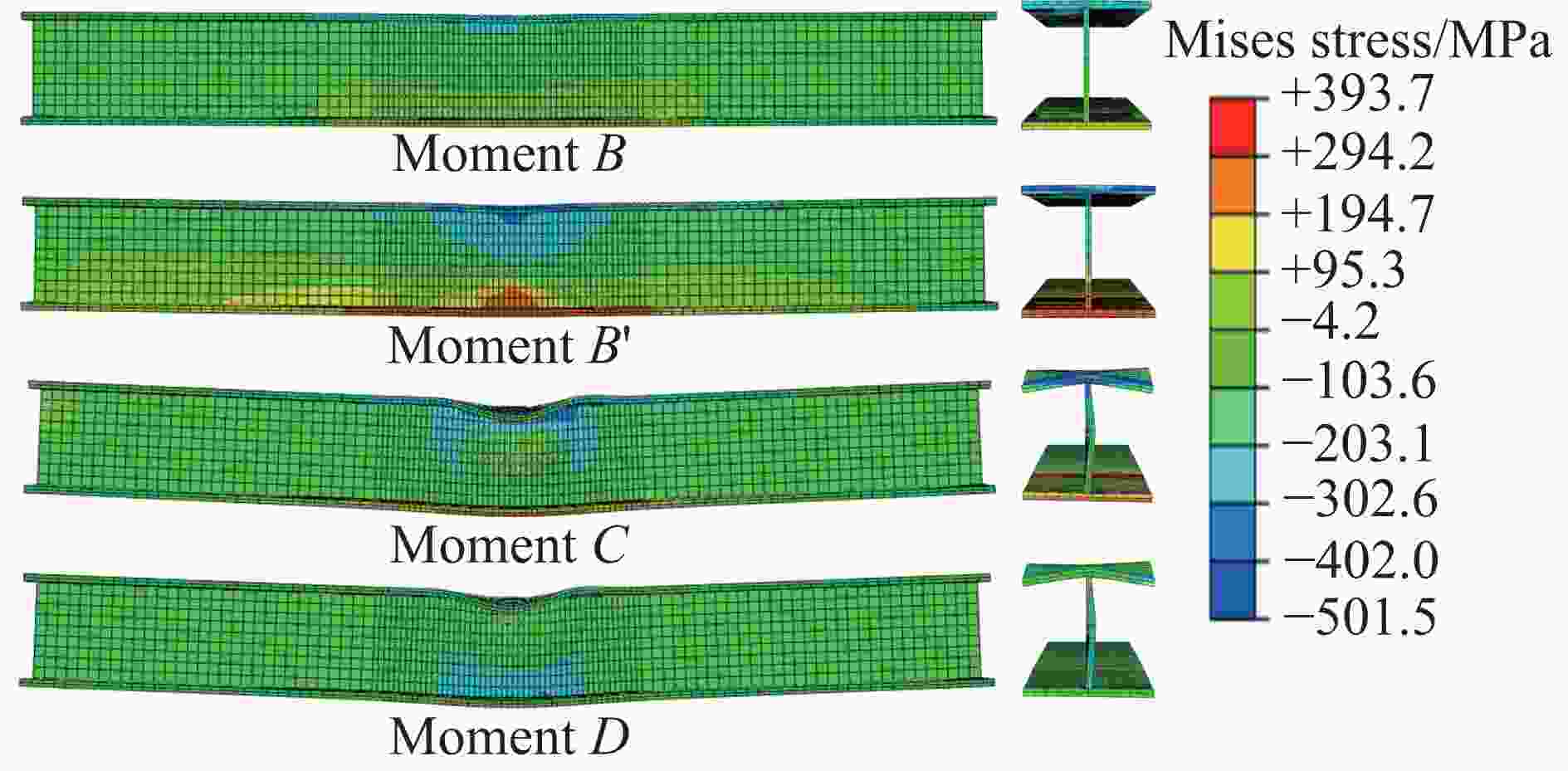

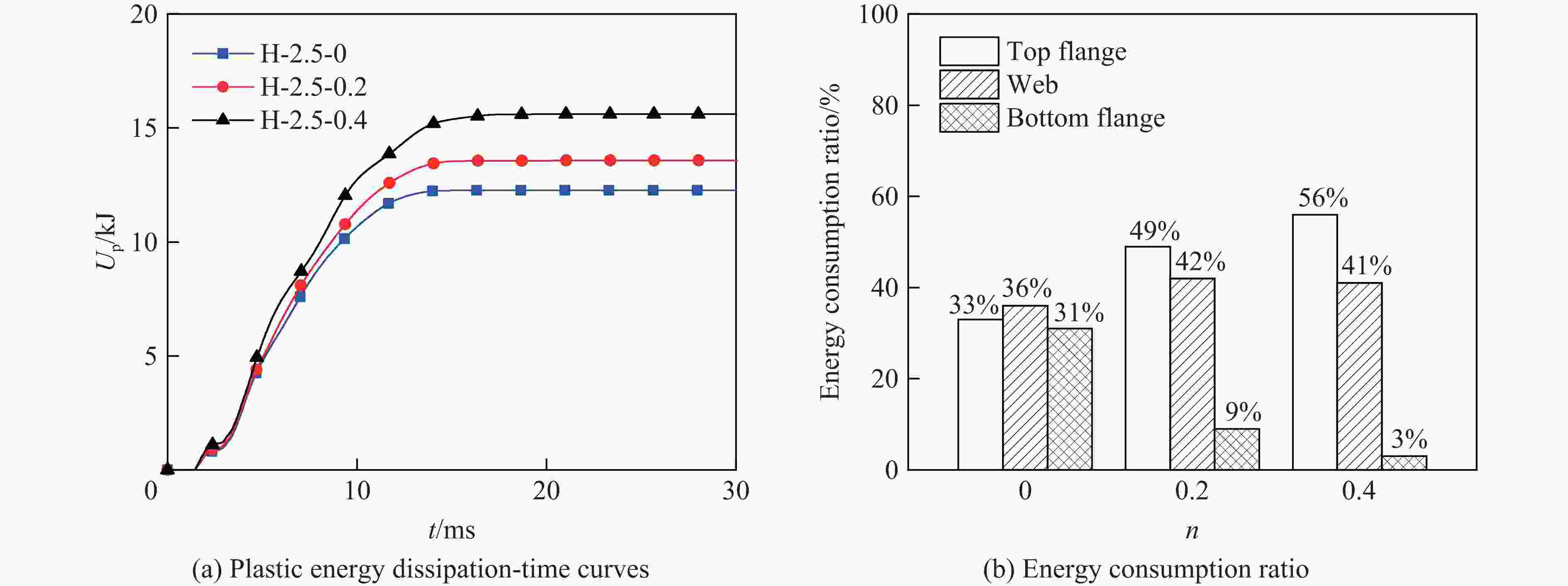

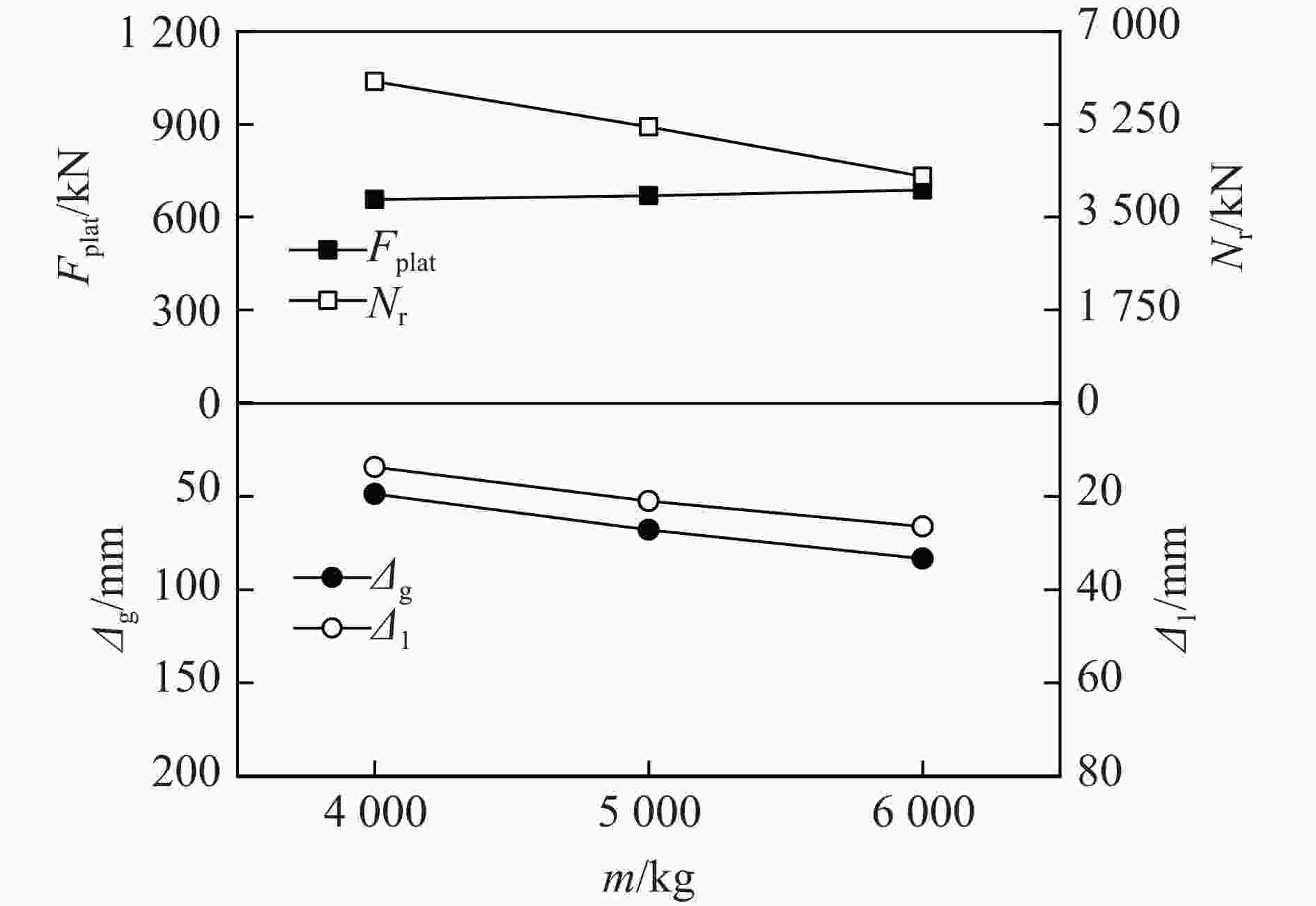

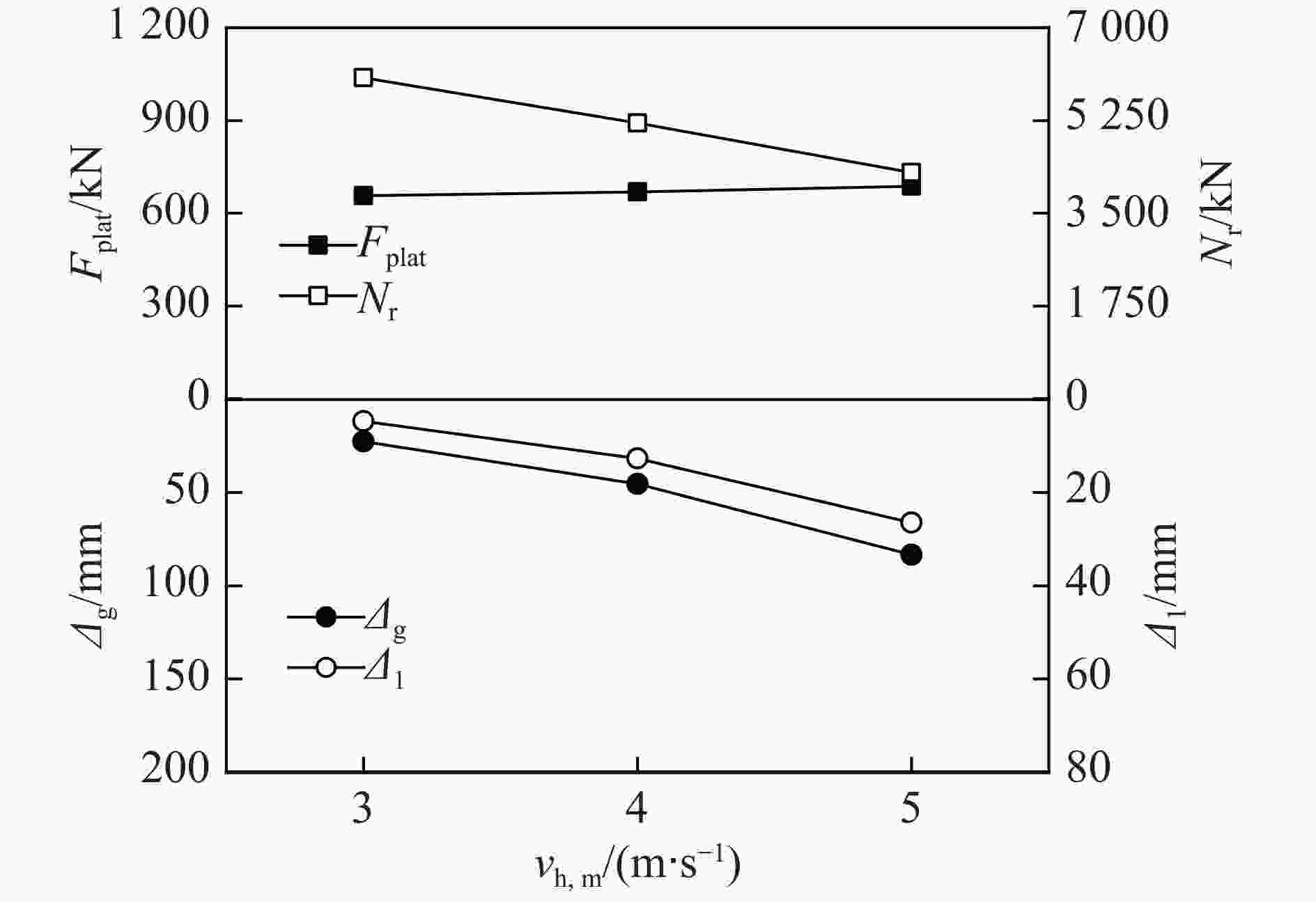

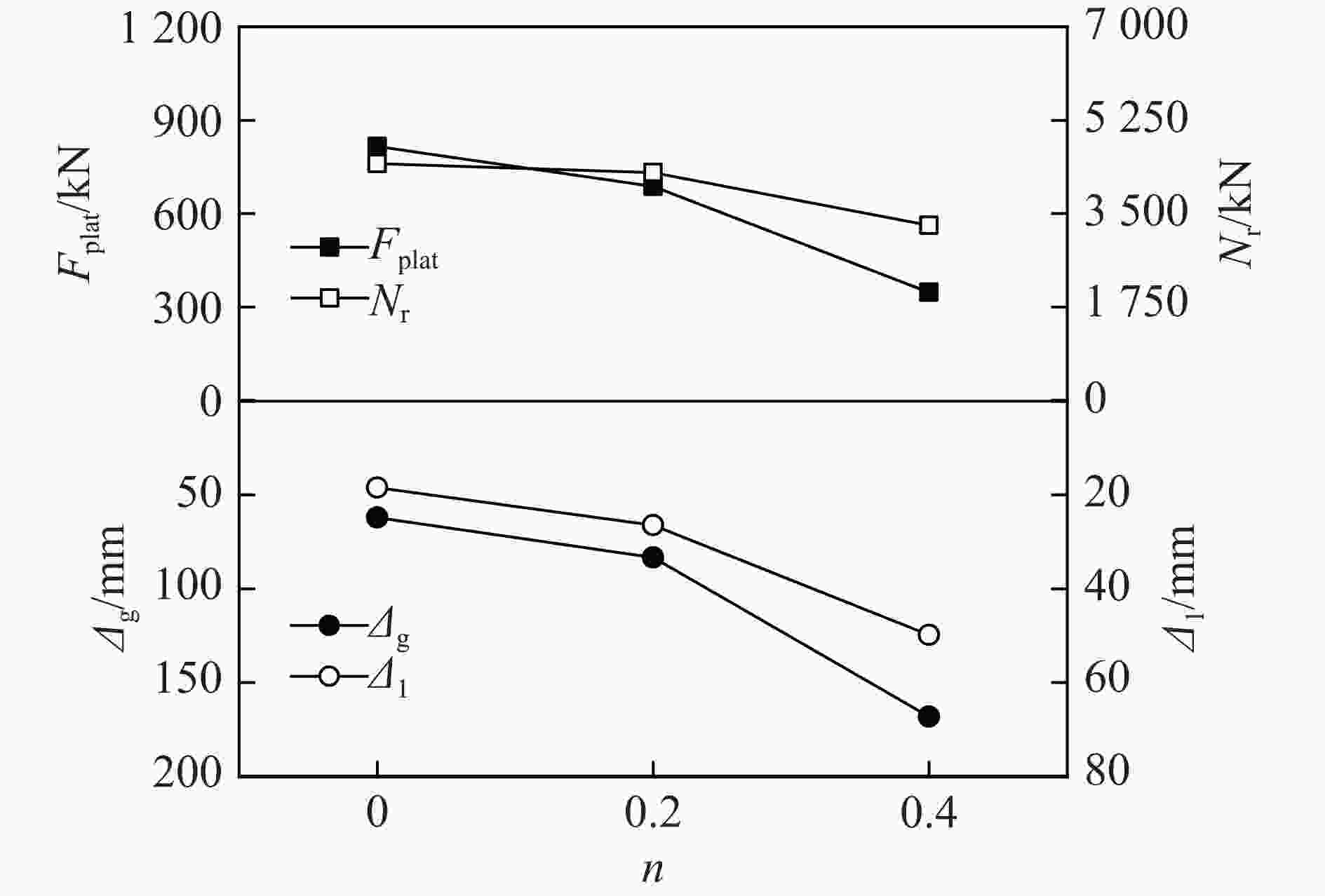

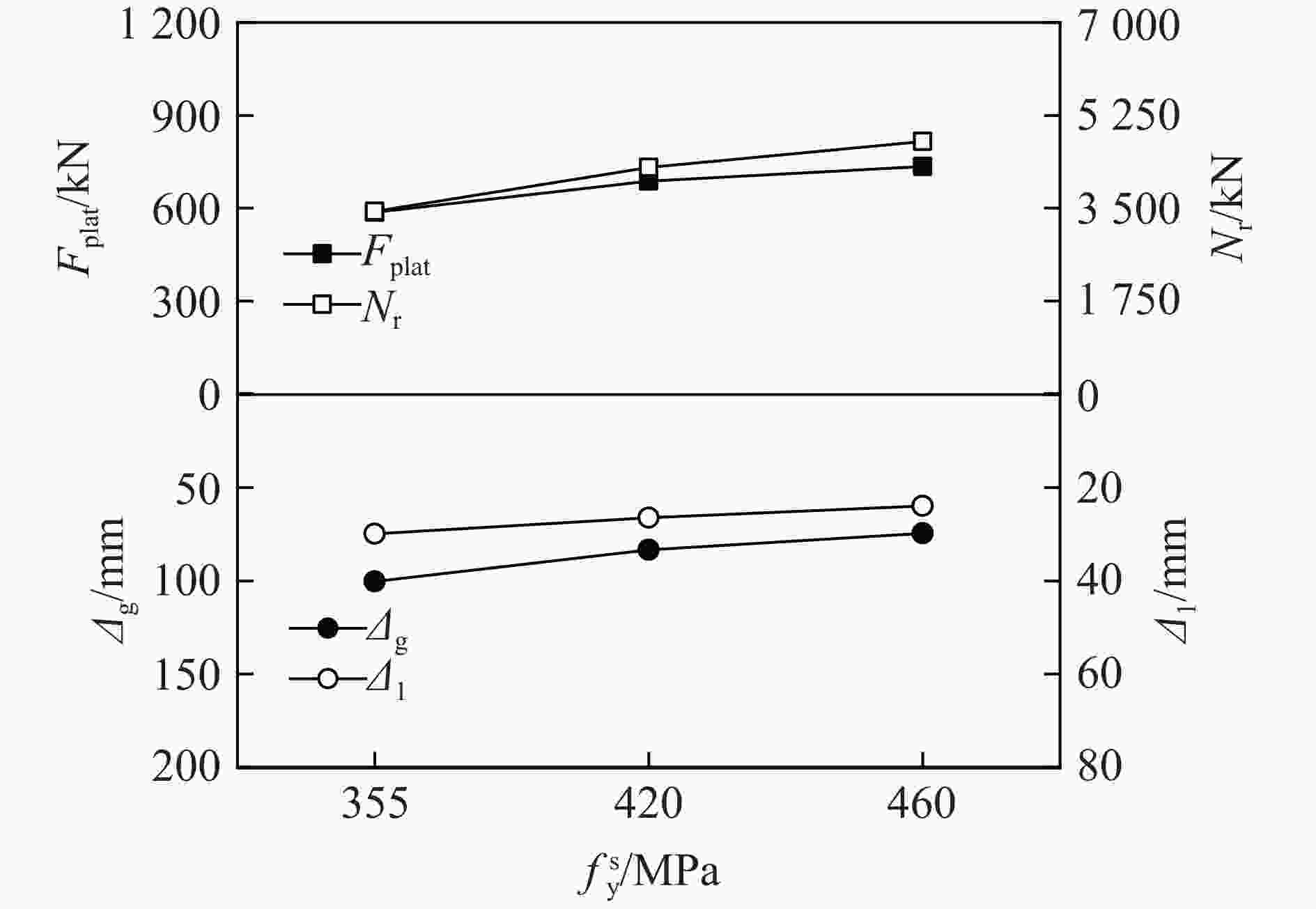

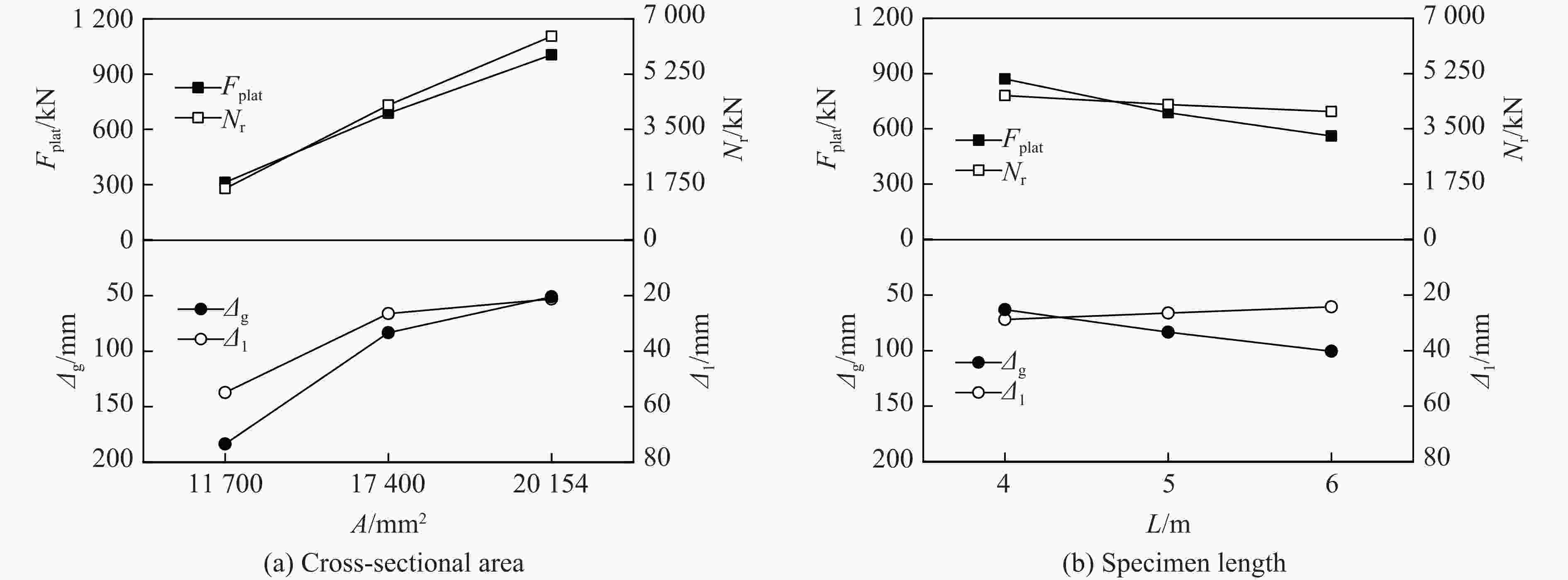

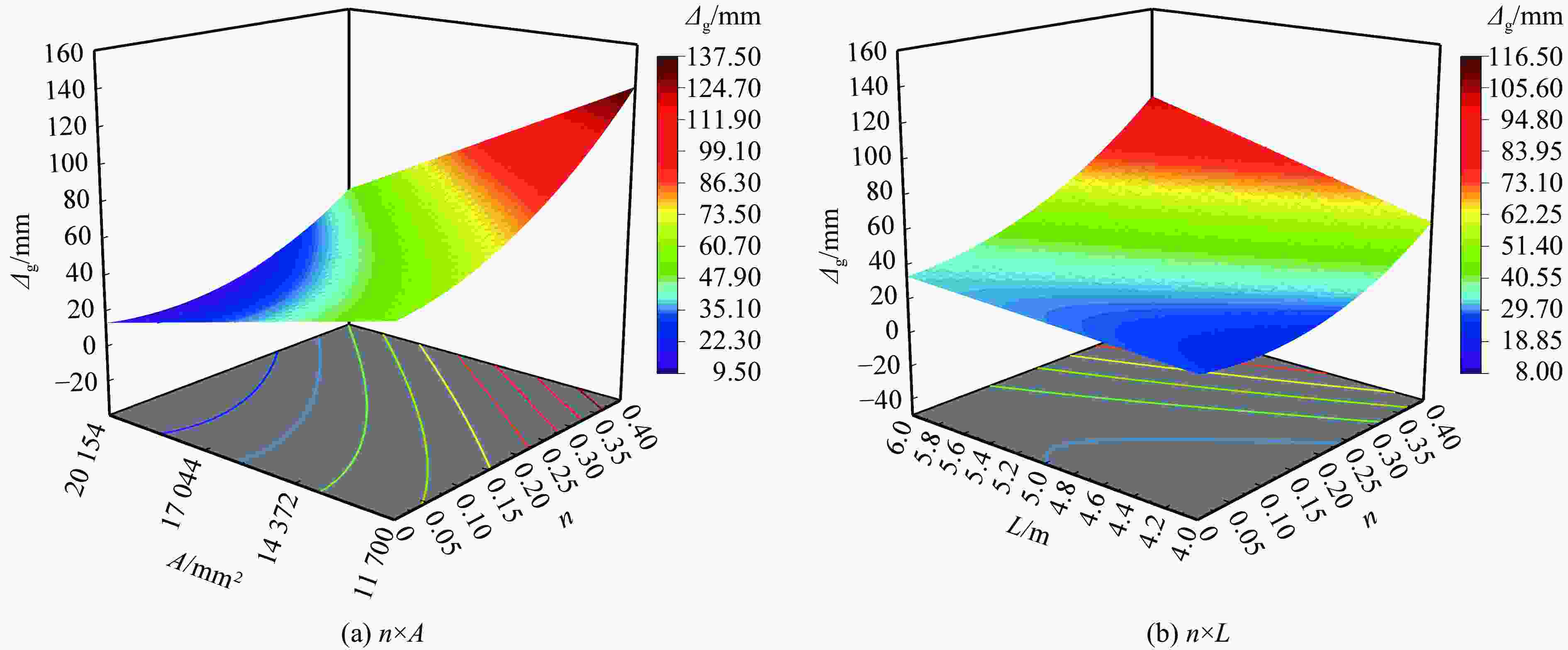

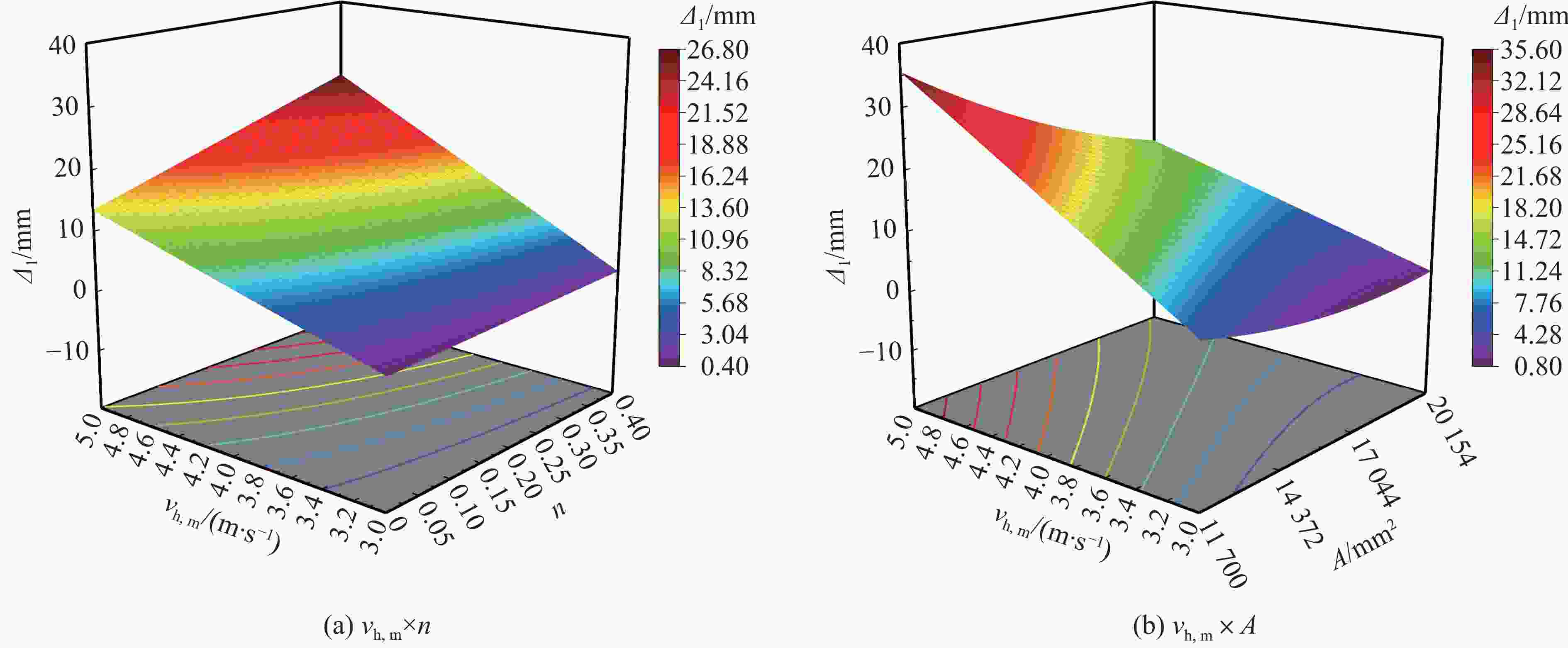

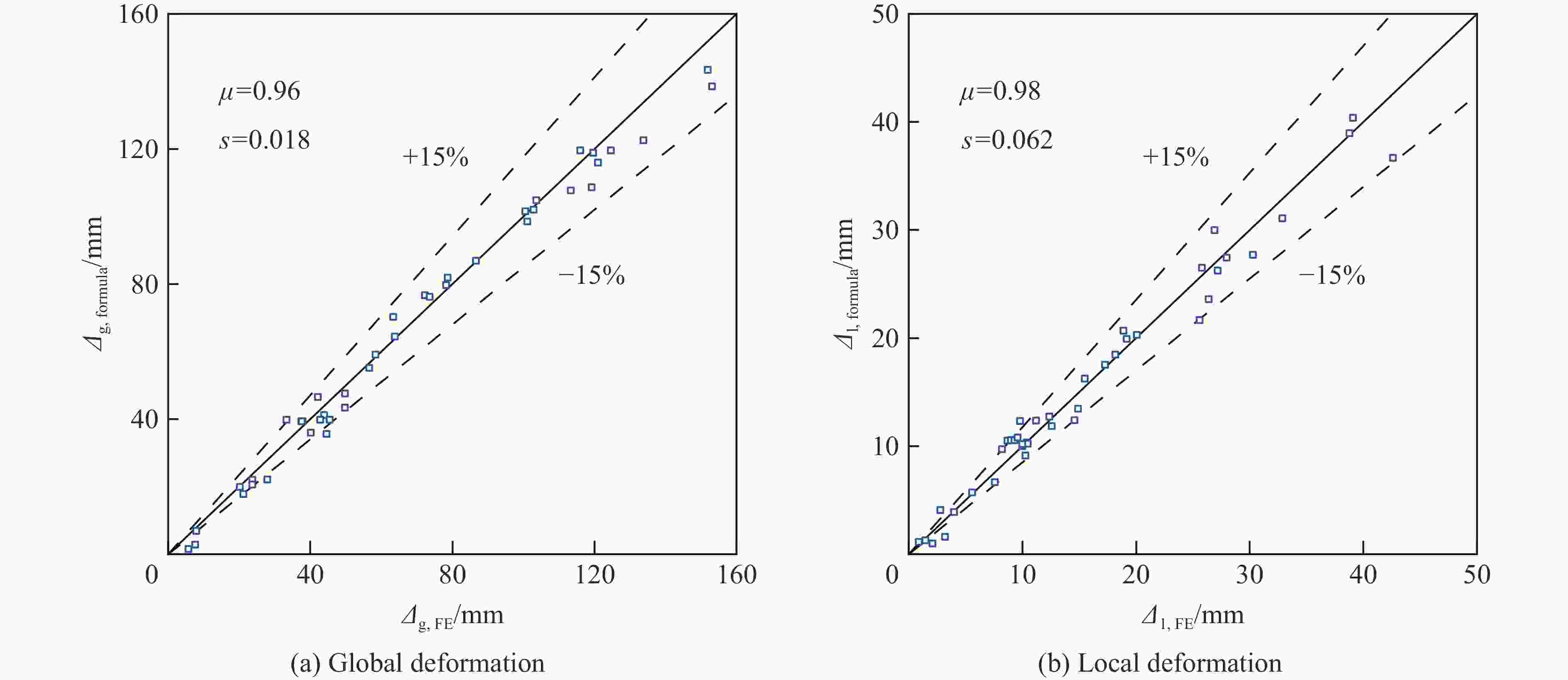

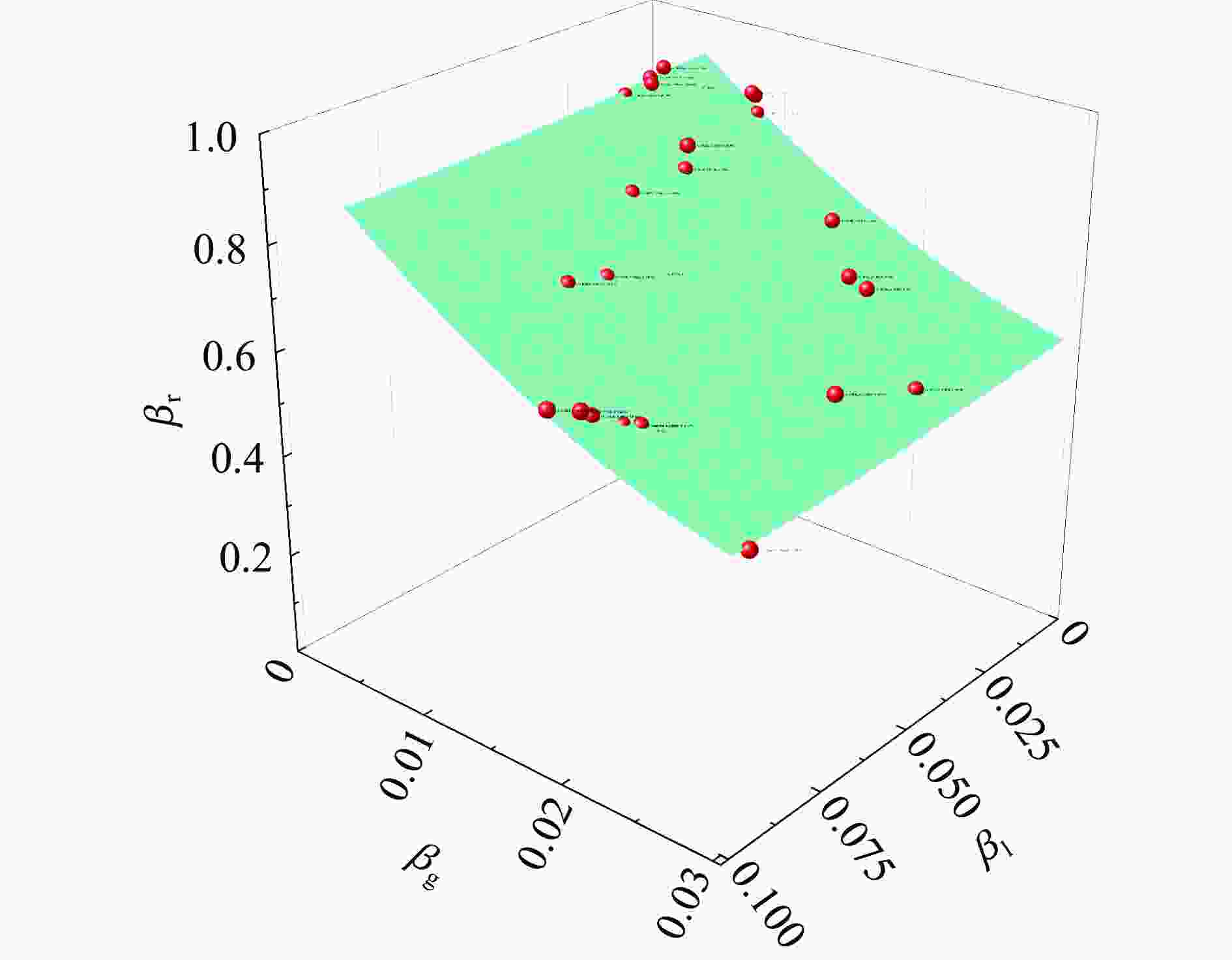

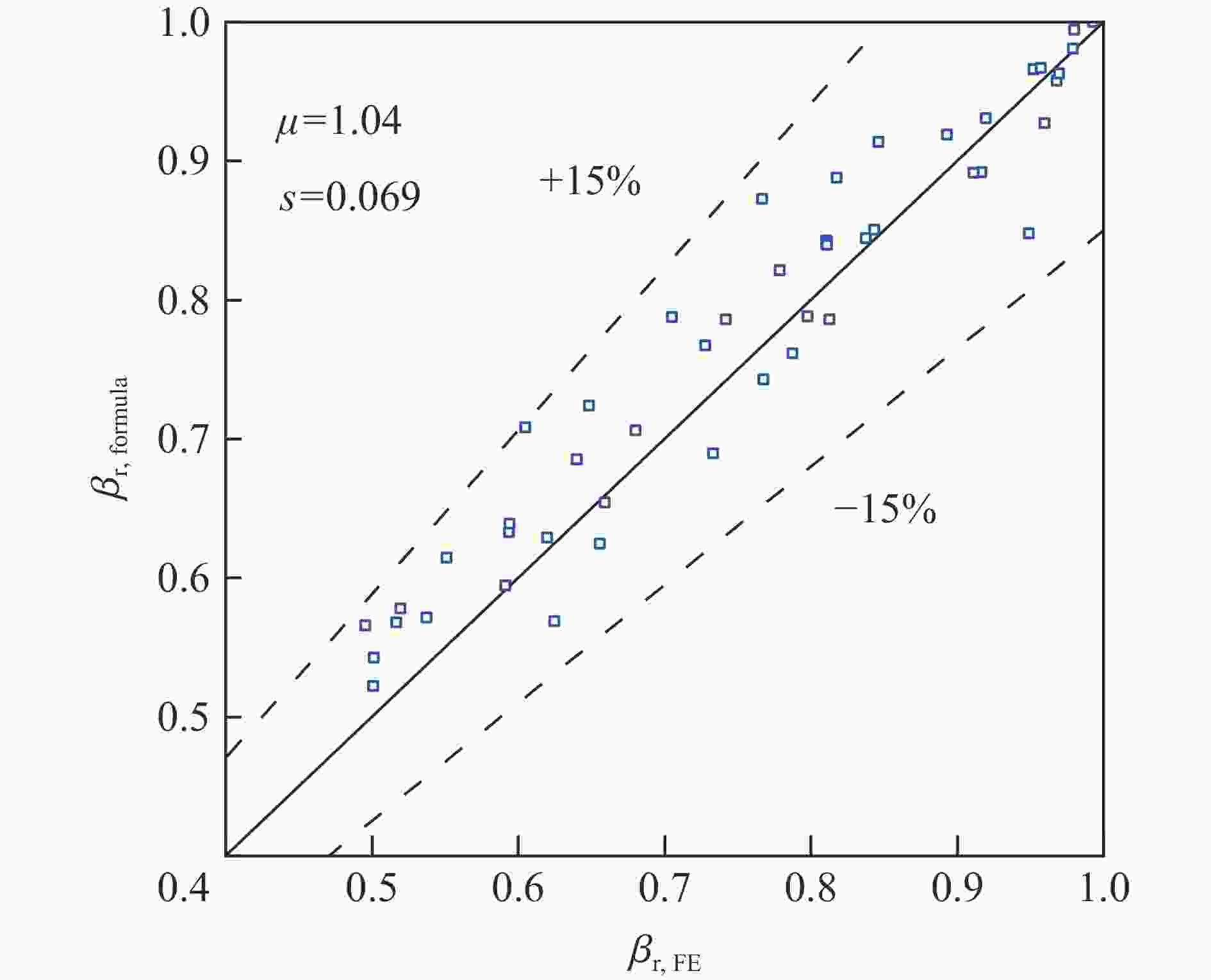

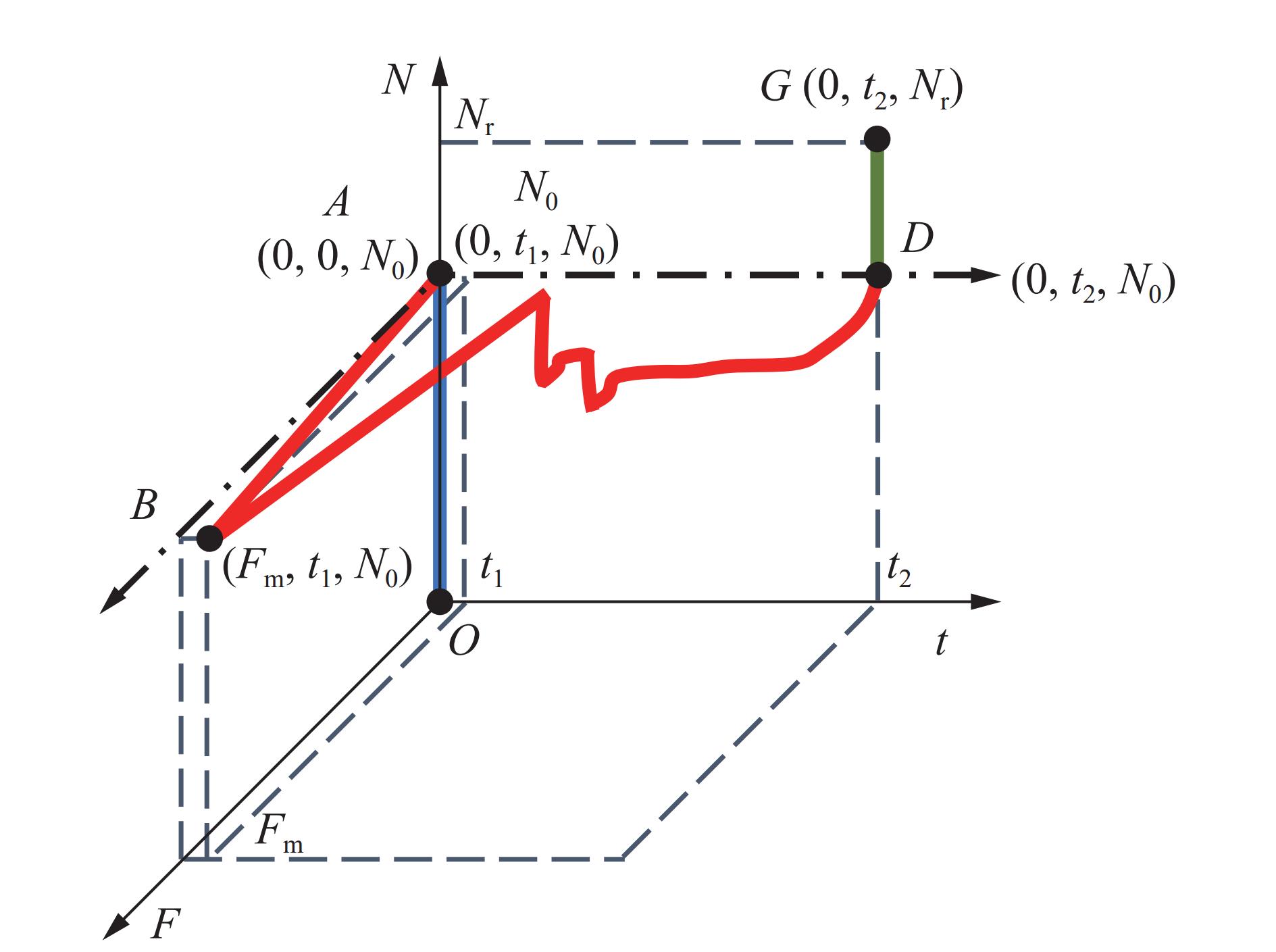

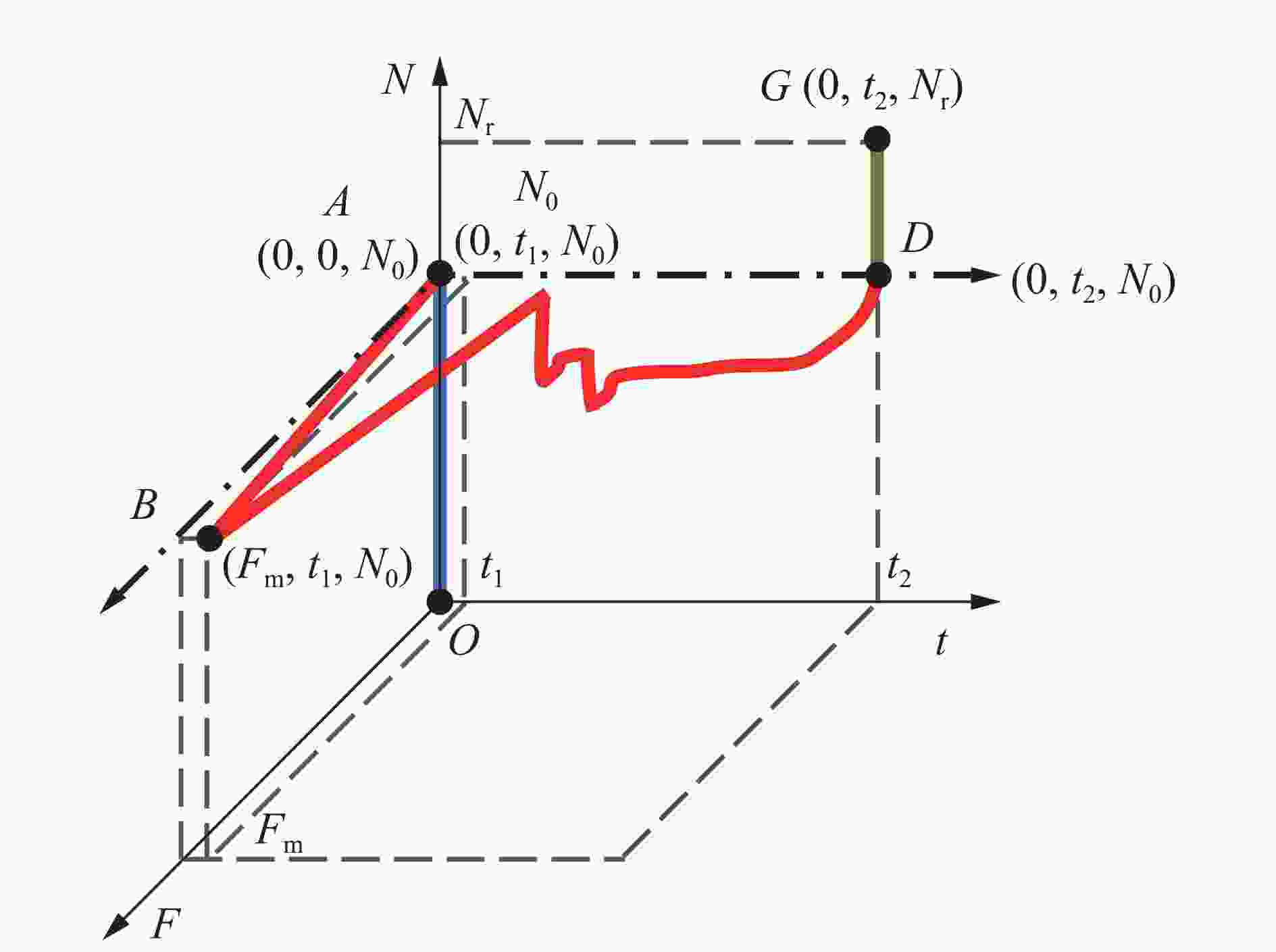

摘要: 鉴于H型钢柱在工业厂房、停车场等场合应用时易遭受吊装载荷和车辆撞击,在前期试验研究的基础上,通过有限元对H型钢柱撞击中及撞击后的力学性能开展全过程分析。首先,通过机理分析,获得了不同轴压比影响下试件的变形特征、应力和耗能发展。结果表明:侧向撞击下,H型钢柱以整体变形为主,上翼缘和腹板分别发生局部凹陷和平面外屈曲;撞击力时程曲线呈现明显的平台段,预加轴力明显削弱试件的抗撞能力。其次,建立了108个参数分析模型,重点探究了荷载参数(撞击质量m、撞击速度vh,m和轴压比n)、材料参数(屈服强度fys)和几何参数(截面面积A和试件长度L)对撞击力、撞击变形和剩余承载力的影响,发现随着撞击质量m、撞击速度vh,m和轴压比n的增大,H型钢柱的整体和局部变形增大,剩余承载力降低。此外,钢材强度的提高有效增强了试件的抗撞性能。最后,基于响应面法提出了多因子交互影响的撞击下整体和局部变形及撞击后剩余承载力的预测公式,可用于H型钢柱撞击全过程损伤评估与设计。Abstract: H-section steel columns have been widely employed in industrial buildings and parking lots, etc., which are vulnerable to crane-loading or vehicle collisions. Based on above background and previous experimental studies, the lateral impact model and residual load-carrying capacity model are established by using Abaqus finite element software to analyze the performance of H-section steel columns during and after impact loading. Firstly, the working mechanism, including the deformation characteristics, stress evolution and energy dissipation, is analyzed. Results indicate that under impact loading, the deformation pattern is mainly dominated by the global deformation, with the local deformation of the upper flange and out-of-plane buckling of the web. The time history curve of impact force exhibits an obvious plateau phase, and the existence of the pre-axial compression clearly reduces the impact resistance of the specimens. In general, H-section steel columns present favorable ductility performance during impact loading. Subsequently, a total of 108 parametric models are constructed, and the effects of load parameters (impact mass, impact velocity and axial load ratio), material parameter (steel yield strength) and geometric parameters (sectional area and specimen length) on the impact force, deformation, and residual load-carrying capacity are emphatically studied. The results show that as the impact mass, impact velocity, and/or pre-axial loading ratio increase, both the global and local deformations of H-section steel column will increase, while the residual load-carrying capacity will decrease. Finally, by considering the multi-factor interactions, the formulas for predicting global deformation and local deformation during impact and the residual load-carrying performance after impact are proposed by using response surface method. Results show that pre-axial loading is a key factor affecting global deformation, while the impact velocity mainly affects local deformation. In addition, both the pre-axial loading and impact velocity significantly interact with other parameters. The proposed formulas can be employed for the damage evaluation and design of H-section steel columns during the whole impact process and after impact event.

-

试件编号 n m/kg vh,m/(m∙s−1) H/m U/kJ 试件编号 n m/kg vh,m/(m∙s−1) H/m U/kJ H-0-a H-2.5-0.4-a 0.4 521 7.00 2.5 12.8 H-2.5-0-a 0 521 7.00 2.5 12.8 H-2.5-0.4-b 0.4 521 7.00 2.5 12.8 H-2.5-0-b 0 521 7.00 2.5 12.8 H-3.0-0-a 0 521 7.67 3.0 15.3 H-2.5-0-c 0 521 7.00 2.5 12.8 H-3.0-0-b 0 521 7.67 3.0 15.3 H-2.5-0.2-a 0.2 521 7.00 2.5 12.8 H-3.0-0.2-a 0.2 521 7.67 3.0 15.3 H-2.5-0.2-b 0.2 521 7.00 2.5 12.8 H-3.0-0.4-a 0.4 521 7.67 3.0 15.3 注:试件编号中2.5和3.0代表落锤释放高度,0、0.2和0.4代表预加轴压比,a、b和c表示同组3个重复试件。 区域 $f_{\mathrm{y}}^{\mathrm{s}} $/MPa E/GPa fu/MPa ξ/% 区域 $f_{\mathrm{y}}^{\mathrm{s}} $/MPa E/GPa fu/MPa ξ/% 腹板 290.1 206 421.1 27.0 翼缘 251.6 202 409.8 34.8 表 3 参数取值

Table 3. Parameter values

h/

mmb/

mmww/

mmwf/

mmm/

kgvh,m/

(m∙s−1)n $f_{\mathrm{y}}^{\mathrm{s}} $/

MPaA/

mm2L/

m300 300 10 15 4 000 3 0 355 11700 4 350 350 12 19 5 000 4 0.2 420 17400 5 400 400 13 21 6 000 5 0.4 460 20154 6 -

[1] HUO J S, ZHANG J Q, LIU Y Z, et al. Dynamic behaviour and catenary action of axially-restrained steel beam under impact loading [J]. Structures, 2017, 11: 84–96. DOI: 10.1016/j.istruc.2017.04.005. [2] DANTIMO M, LATOUR M, RIZZANO G, et al. Experimental and numerical assessment of steel beams under impact loadings [J]. Journal of Constructional Steel Research, 2019, 158: 230–247. DOI: 10.1016/j.jcsr.2019.03.029. [3] Al-THAIRY H, WANG Y C. A numerical study of the behaviour and failure modes of axially compressed steel columns subjected to transverse impact [J]. International Journal of Impact Engineering, 2011, 38(8/9): 732–744. DOI: 10.1016/j.ijimpeng.2011.03.005. [4] Al-THAIRY H, WANG Y C. An assessment of the current Eurocode 1 design methods for building structure steel columns under vehicle impact [J]. Journal of Constructional Steel Research, 2013, 88: 164–171. DOI: 10.1016/j.jcsr.2013.05.013. [5] Al-THAIRY H, WANG Y C. Simplified FE vehicle model for assessing the vulnerability of axially compressed steel columns against vehicle frontal impact [J]. Journal of Constructional Steel Research, 2014, 102: 190–203. DOI: 10.1016/j.jcsr.2014.07.005. [6] AL-THAIRY H A B, WANG Y. Behaviour and design of steel columns subjected to vehicle impact [M]. Zurich: Trans Tech Publications Ltd, 2014. DOI: 10.4028/www.scientific.net/AMM.566.193. [7] XIANG S Y, HE Y J, ZHOU X H, et al. Continuous twice-impact analysis of steel parking structure columns [J]. Journal of Constructional Steel Research, 2021, 187: 106989. DOI: 10.1016/j.jcsr.2021.106989. [8] 王蕊, 郭昭胜, 裴畅. 局部屈曲变形损伤对H型钢柱竖向剩余承载力影响的试验研究 [J]. 建筑结构, 2014, 44(21): 17–22. DOI: 10.19701/j.jzjg.2014.21.004.WANG R, GUO Z S, PEI C. Experimental study on vertical residual bearing capacity of H-shaped steel column with local buckling deformation [J]. Building Structure, 2014, 44(21): 17–22. DOI: 10.19701/j.jzjg.2014.21.004. [9] BAI Y, WANG R, CUI J L. Residual bearing capacity numerical simulation and theoretical analysis of H-shaped steel column impacted under different axis pressure [J]. Advanced Materials Research, 2014, 1065/1066/1067/1068/1069: 1097-1100. DOI: 10.4028/www.scientific.net/AMR.1065-1069.1097. [10] ZHAO H, WANG R, LI Q M, et al. Experimental and numerical investigation on impact and post-impact behaviours of H-shaped steel members [J]. Engineering Structures, 2020, 216: 110750. DOI: 10.1016/j.engstruct.2020.110750. [11] WANG R, YANG X, ZHAO H, et al. Damage evaluation of axial-loaded H-section steel columns during and after impact loading [J]. Journal of Constructional Steel Research, 2022, 196: 107426. DOI: 10.1016/j.jcsr.2022.107426. [12] MAKAREM F S, ABED F. Nonlinear finite element modeling of dynamic localizations in high strength steel columns under impact [J]. International Journal of Impact Engineering, 2013, 52: 47–61. DOI: 10.1016/j.ijimpeng.2012.10.006. [13] CHEN Y, WAN J, WANG K, et al. Residual axial bearing capacity of square steel tubes after lateral impact [J]. Journal of Constructional Steel Research, 2017, 137: 325–341. DOI: 10.1016/j.jcsr.2017.06.019. [14] 韩林海. 钢管混凝土结构: 理论与实践 [M]. 3版. 北京: 科学出版社, 2016: 68–77.HAN L H. Concrete filled steel tubular structures: theory and practice [M] 3rd ed. Beijing: Science Press, 2016: 68–77. [15] 侯川川. 低速横向冲击荷载下圆钢管混凝土构件的力学性能研究 [D]. 北京: 清华大学, 2012.HOU C C. Study on performance of circular concrete-filled steel tubular (CFST) members under low velocity transverse impact [D]. Beijing: Tsinghua University, 2012. [16] COWPER G, SYMONDS P S. Strain-hardening and strain-rate effects in the impact loading of cantilever beams [R]. 1957. DOI: 10.21236/ad0144762. [17] ABRAMOWICZ W, JONES N. Dynamic axial crushing of square tubes [J]. International Journal of Impact Engineering, 1984, 2(2): 179–208. DOI: 10.1016/0734-743X(84)90005-8. [18] DAI X H, WANG Y C, BAILEY C G. Numerical modelling of structural fire behaviour of restrained steel beam-column assemblies using typical joint types [J]. Engineering Structures, 2010, 32(8): 2337–2351. DOI: 10.1016/j.engstruct.2010.04.009. [19] ZHAO H, MEI S Q, WANG R, et al. Round-ended concrete-filled steel tube columns under impact loading: test, numerical analysis and design method [J]. Thin-Walled Structures, 2023, 191: 111020. DOI: 10.1016/j.tws.2023.111020. [20] ZHAO H, XIE Z W, YANG B H, et al. Impact resistance performance of precast reinforced concrete barriers with grouted sleeve and steel angle-to-plate connections [J]. Engineering Structures, 2024, 316: 118533. DOI: 10.1016/j.engstruct.2024.118533. [21] WANG R, HAN L H, HOU C C. Behavior of concrete filled steel tubular (CFST) members under lateral impact: Experiment and FEA model [J]. Journal of Constructional Steel Research, 2013, 80: 188–201. DOI: 10.1016/j.jcsr.2012.09.003. [22] 孔祥韶, 杨豹, 周沪, 等. 基于响应面法的纤维金属层合板抗弹性能优化设计 [J]. 爆炸与冲击, 2022, 42(4): 043301. DOI: 10.11883/bzycj-2021-0146.KONG X S, YANG B, ZHOU H, et al. Optimal design of ballistic performance of fiber-metal laminates based on the response surface method [J]. Explosion and Shock Waves, 2022, 42(4): 043301. DOI: 10.11883/bzycj-2021-0146. [23] 樊伟, 孙洋, 申东杰, 等. 带主梁的简化模型与响应面联合的桥梁船撞易损性分析方法 [J]. 湖南大学学报(自然科学版), 2021, 48(3): 34–43,135. DOI: 10.16339/j.cnki.hdxbzkb.2021.03.004.FAN W, SUN Y, SHEN D J, et al. Vessel-collision vulnerability analysis method of bridge structures based on simplified model with girders and response surface [J]. Journal of Hunan University (Natural Sciences), 2021, 48(3): 34–43,135. DOI: 10.16339/j.cnki.hdxbzkb.2021.03.004. [24] 樊伟, 毛薇, 庞于涛, 等. 钢筋混凝土柱式桥墩抗车撞可靠度分析研究 [J]. 中国公路学报, 2021, 34(2): 162–176. DOI: 10.19721/j.cnki.1001-7372.2021.02.006.FAN W, MAO W, PANG Y T, et al. Reliability analysis of reinforced concrete column bridge piers subjected to vehicle collisions [J]. China Journal of Highway and Transport, 2021, 34(2): 162–176. DOI: 10.19721/j.cnki.1001-7372.2021.02.006. [25] HAMMOUDI A, MOUSSACEB K, BELEBCHOUCHE C, et al. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates [J]. Construction and Building Materials, 2019, 209: 425–436. DOI: 10.1016/j.conbuildmat.2019.03.119. [26] 郭金龙, 潘爽, 付诗琦. 侧向冲击作用后圆中空夹层钢管混凝土长柱的竖向剩余承载性能研究[J]. 工程力学, 2024, DOI: 10.6052/j.issn.1000-4750.2023.02.0095.GUO J L, PAN S, FU S Q. Study on the vertical residual bearing behaviors of circular concrete-filled double-skin steel tubular long columns after lateral impact [J]. Engineering Mechanics, 2024, DOI: 10.6052/j.issn.1000-4750.2023.02.0095. -

下载:

下载: