Study on dynamic properties and dynamic temperature of concreteunder high-speed impact

-

摘要: 为研究冲击作用下混凝土的动态力学性质和裂纹处的动态温度,采用系统响应速率达到微秒级的自搭建高速红外测温系统,结合霍普金森压杆试验装置,通过静态标定试验拟合了钢-聚丙烯纤维混凝土(steel-polypropylene fiber reinforced concrete,SPFRC)的温度曲线。结果表明:混凝土试件的温度演化与力学性能存在明显的耦合效应,钢纤维体积掺量对动力学性能和温度影响很大,混凝土抗压强度随着钢纤维掺量的增加而增大;其中1.5%钢纤维体积掺量的试件表现出最佳的力学性能,当钢纤维体积掺量达到2.0%时,由于混凝土内部空隙增多,导致其力学性能略有下降。在冲击过程中,裂纹处的动态温度效应呈现“台阶状”特征,温度变化分为两个阶段:在裂纹初期,温度上升缓慢,而裂纹扩展后,摩擦和剪切效应加剧,导致裂纹处温度急剧上升。不同钢纤维体积掺量对温度变化的影响有限,其峰值温度和峰值应力呈现相似的规律,温度的主要变化由裂纹扩展和摩擦效应决定。

-

关键词:

- 钢-聚丙烯纤维混凝土(SPFRC) /

- 动态温度 /

- 红外测温

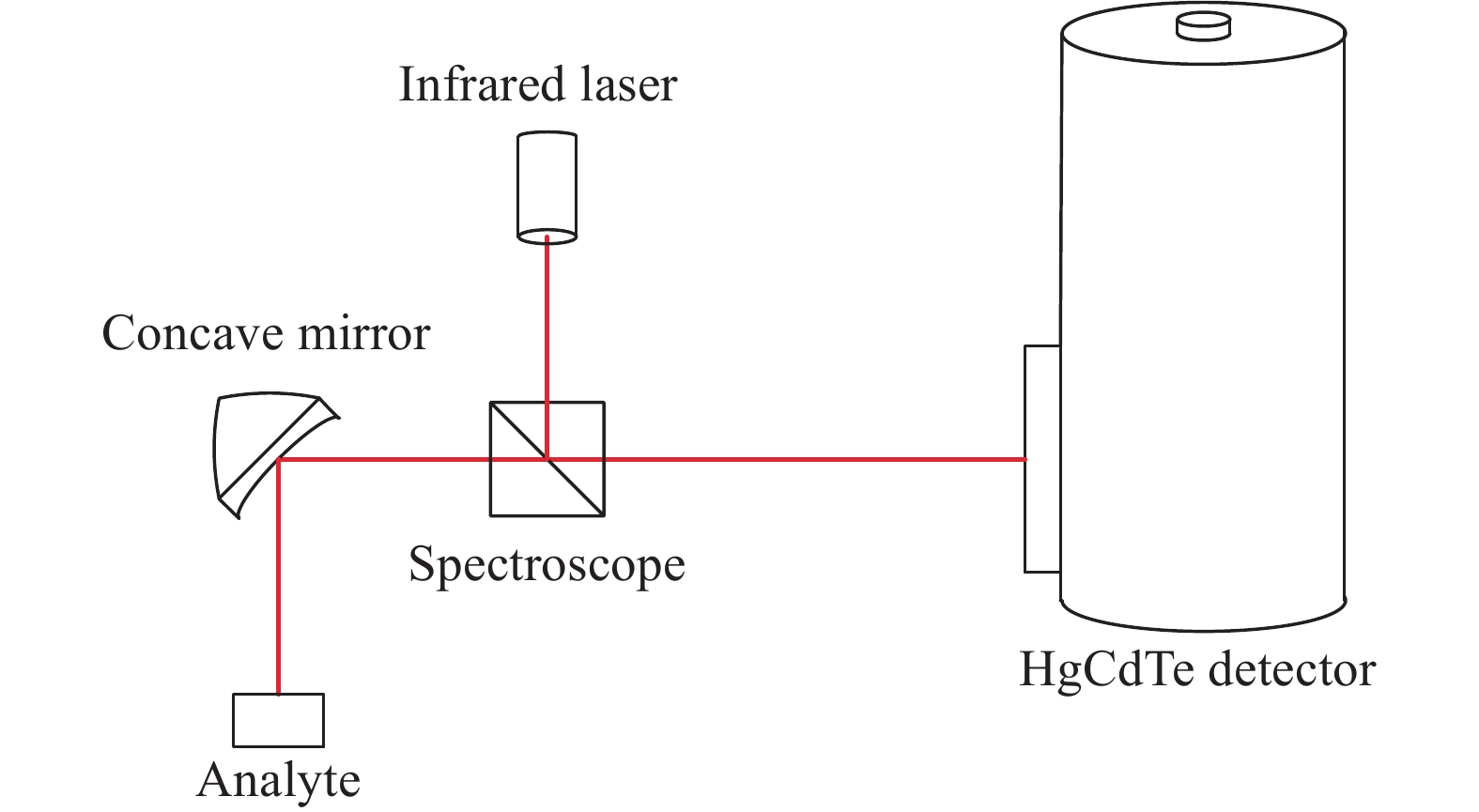

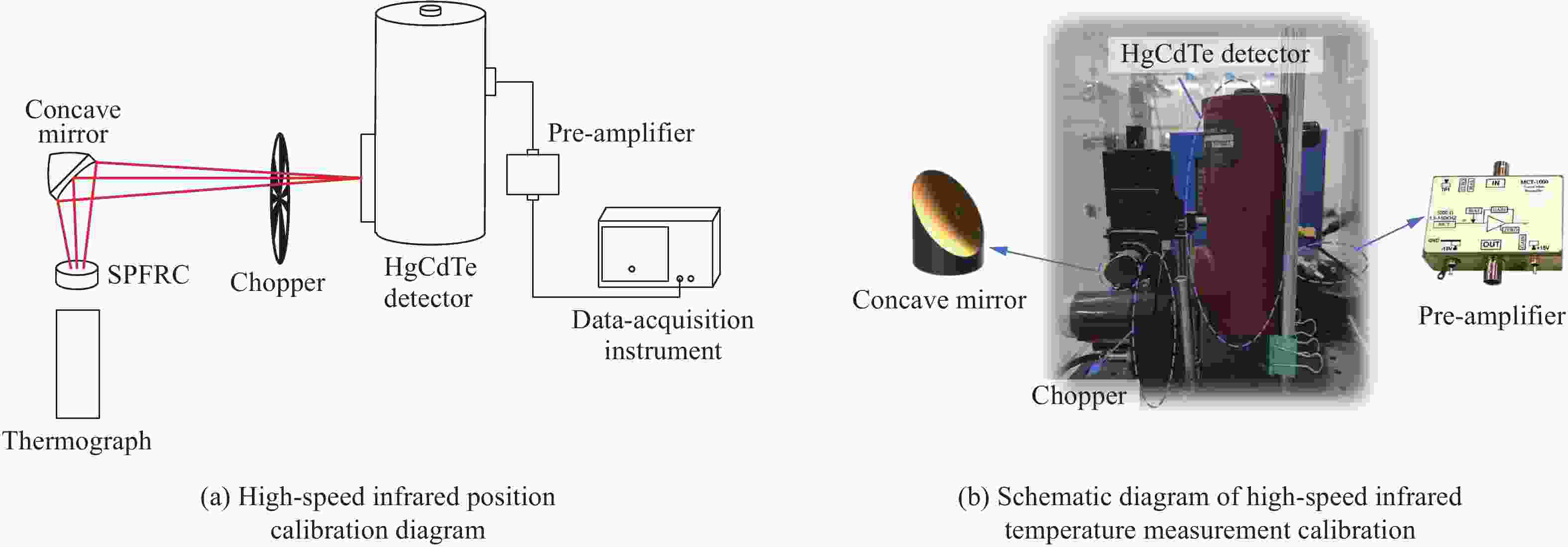

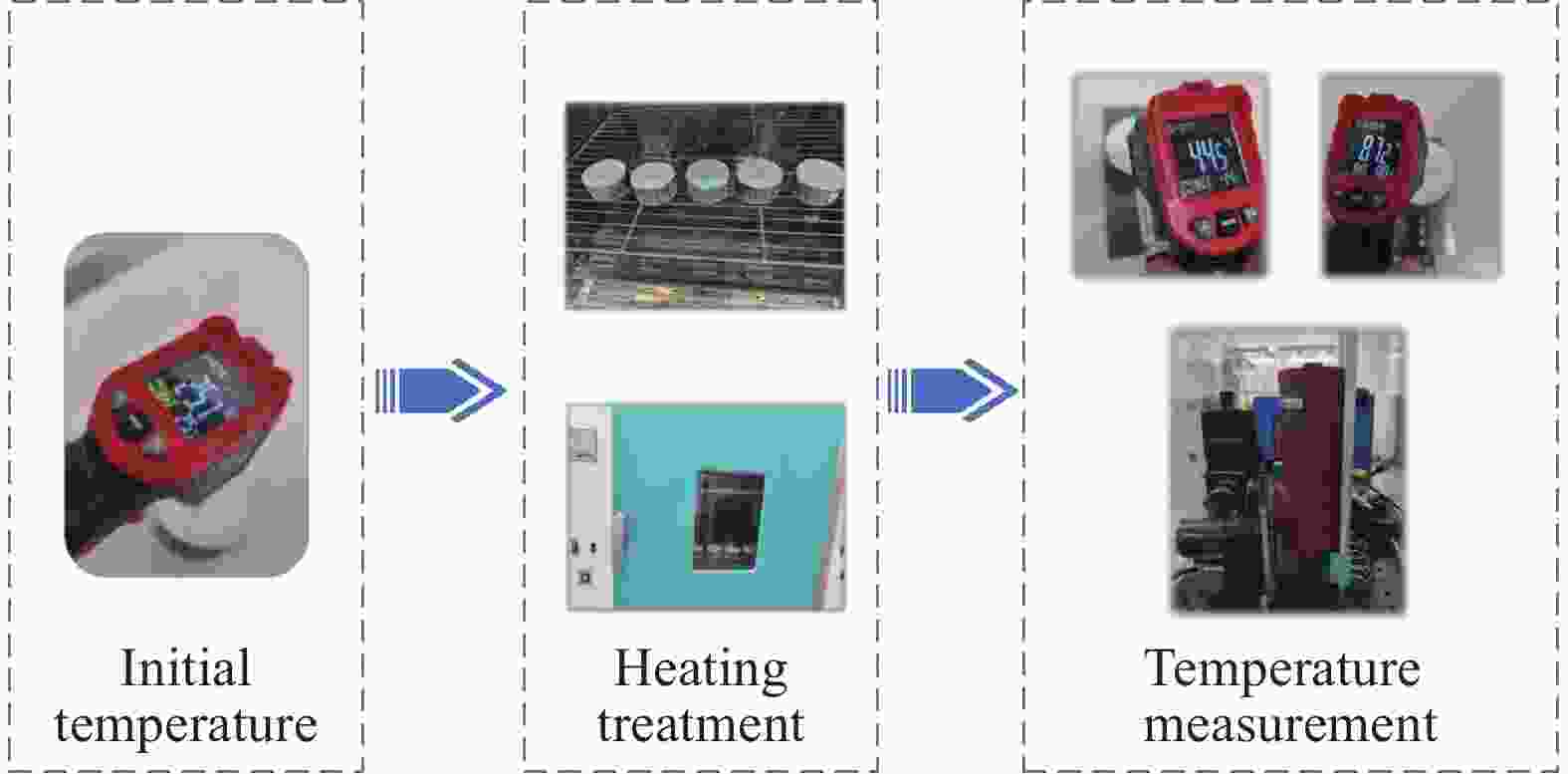

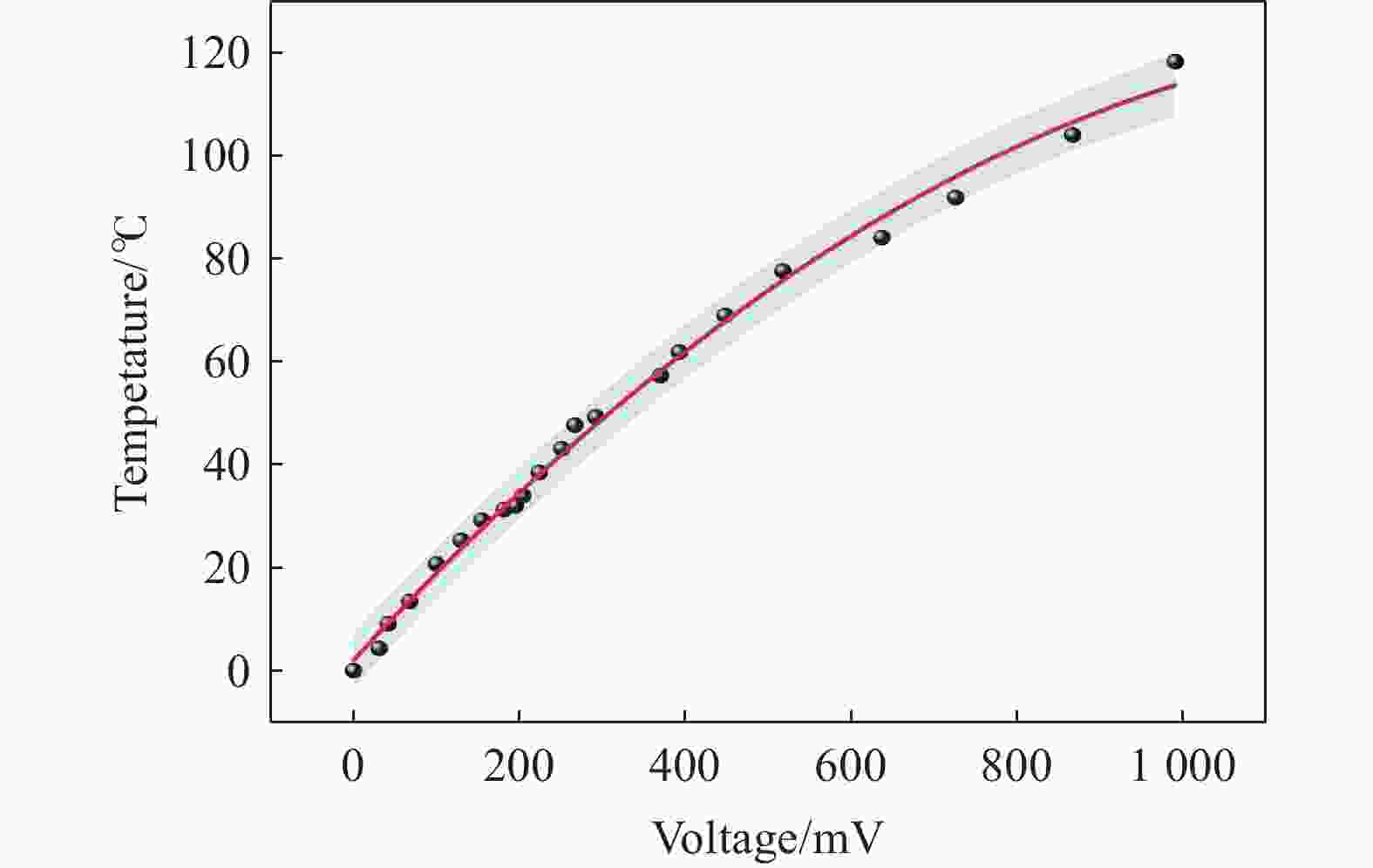

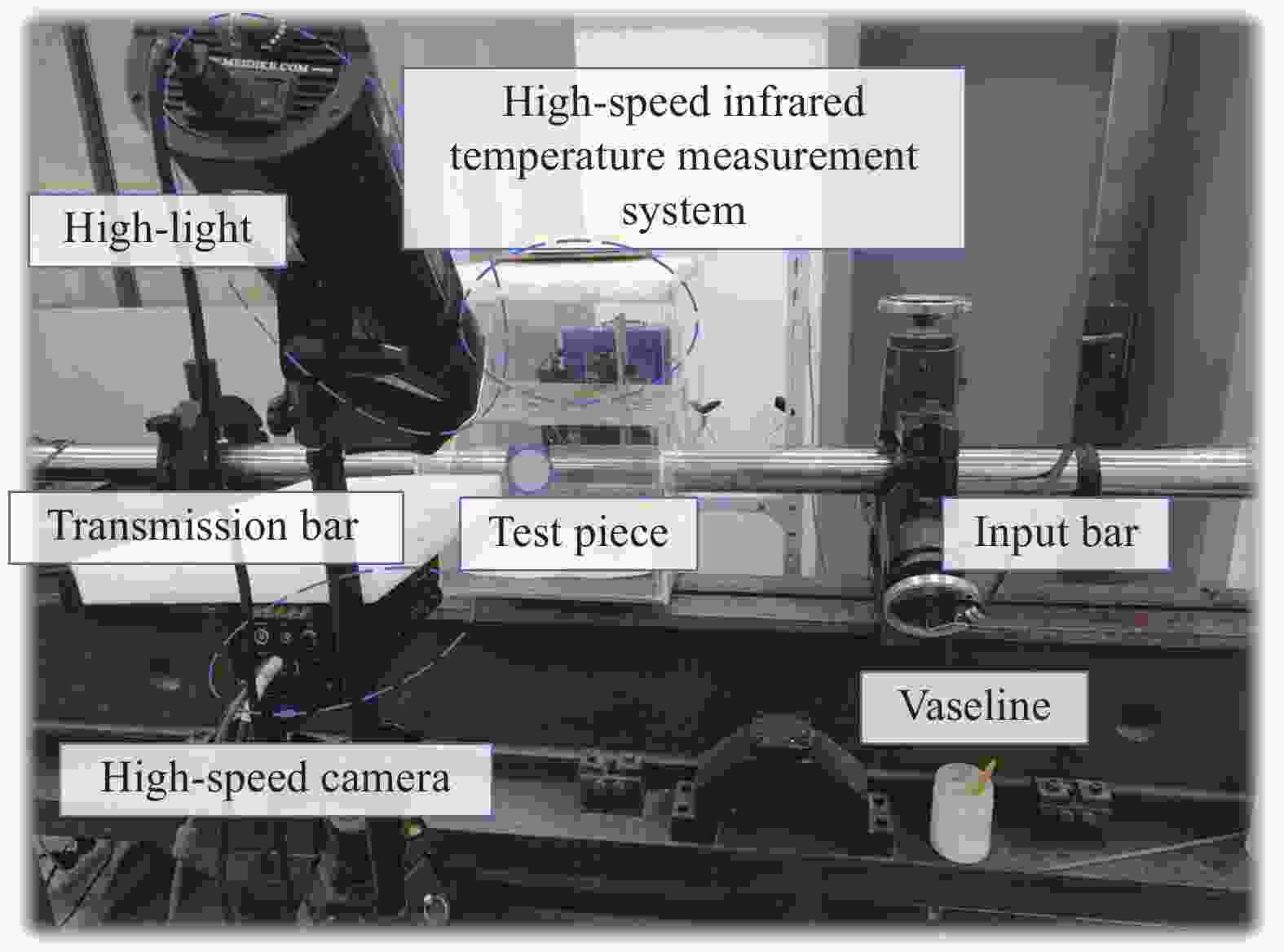

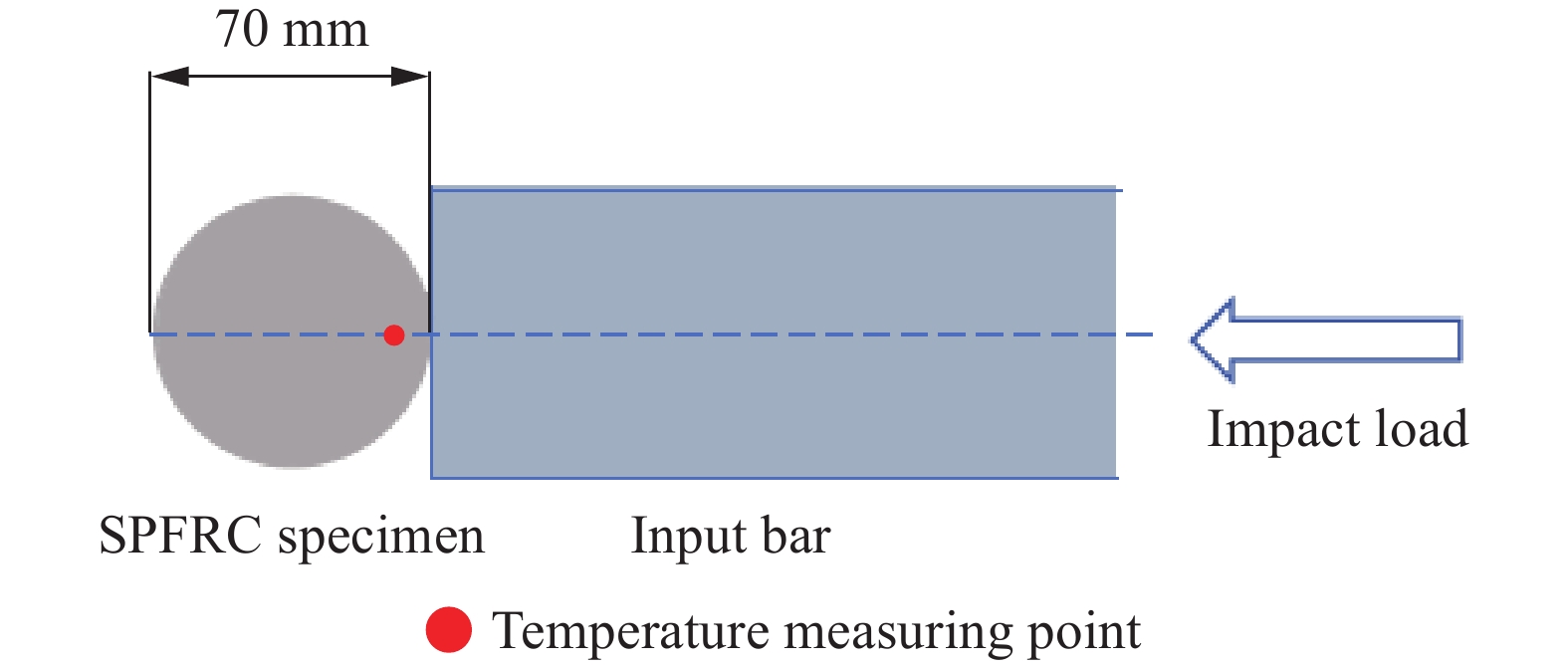

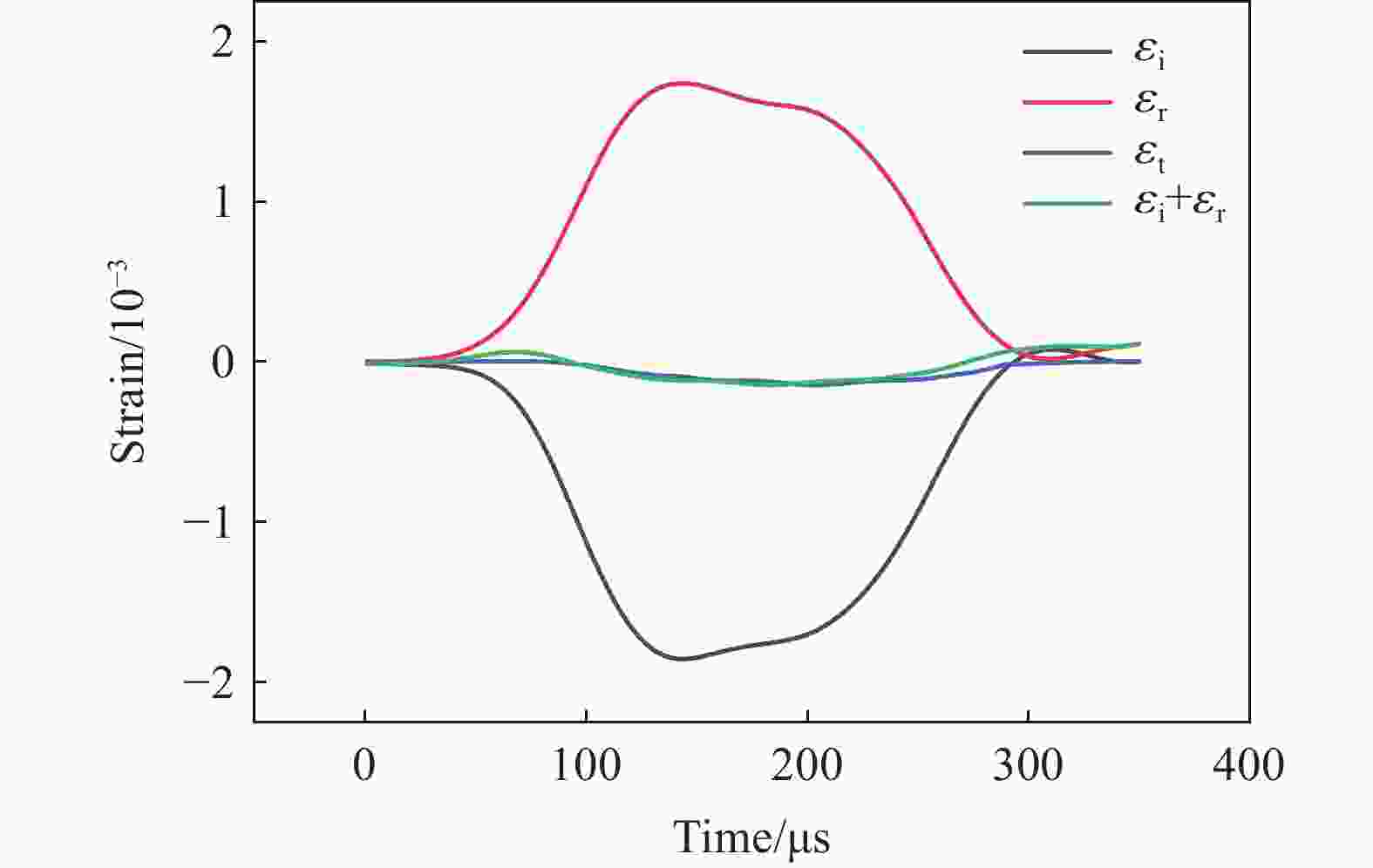

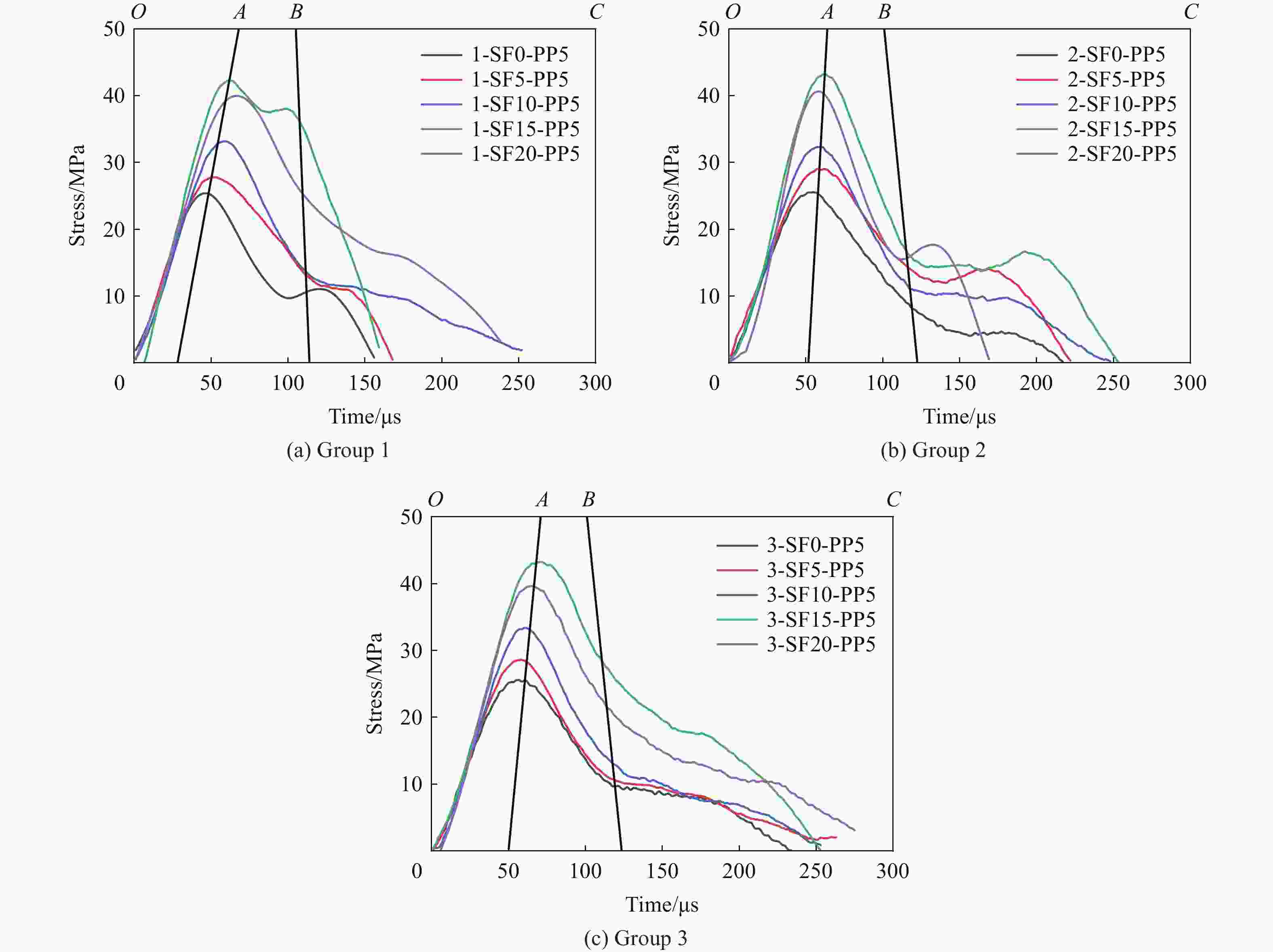

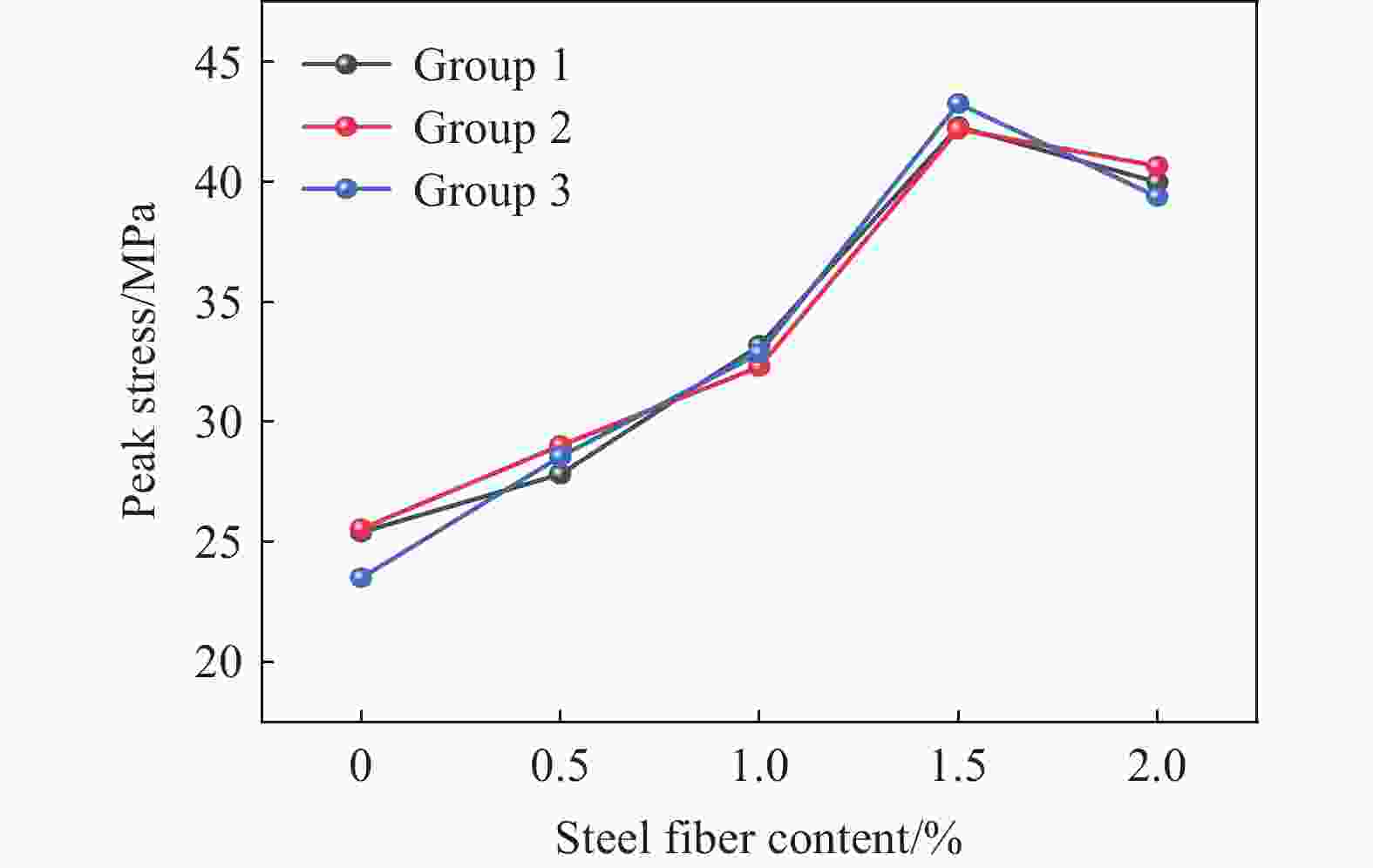

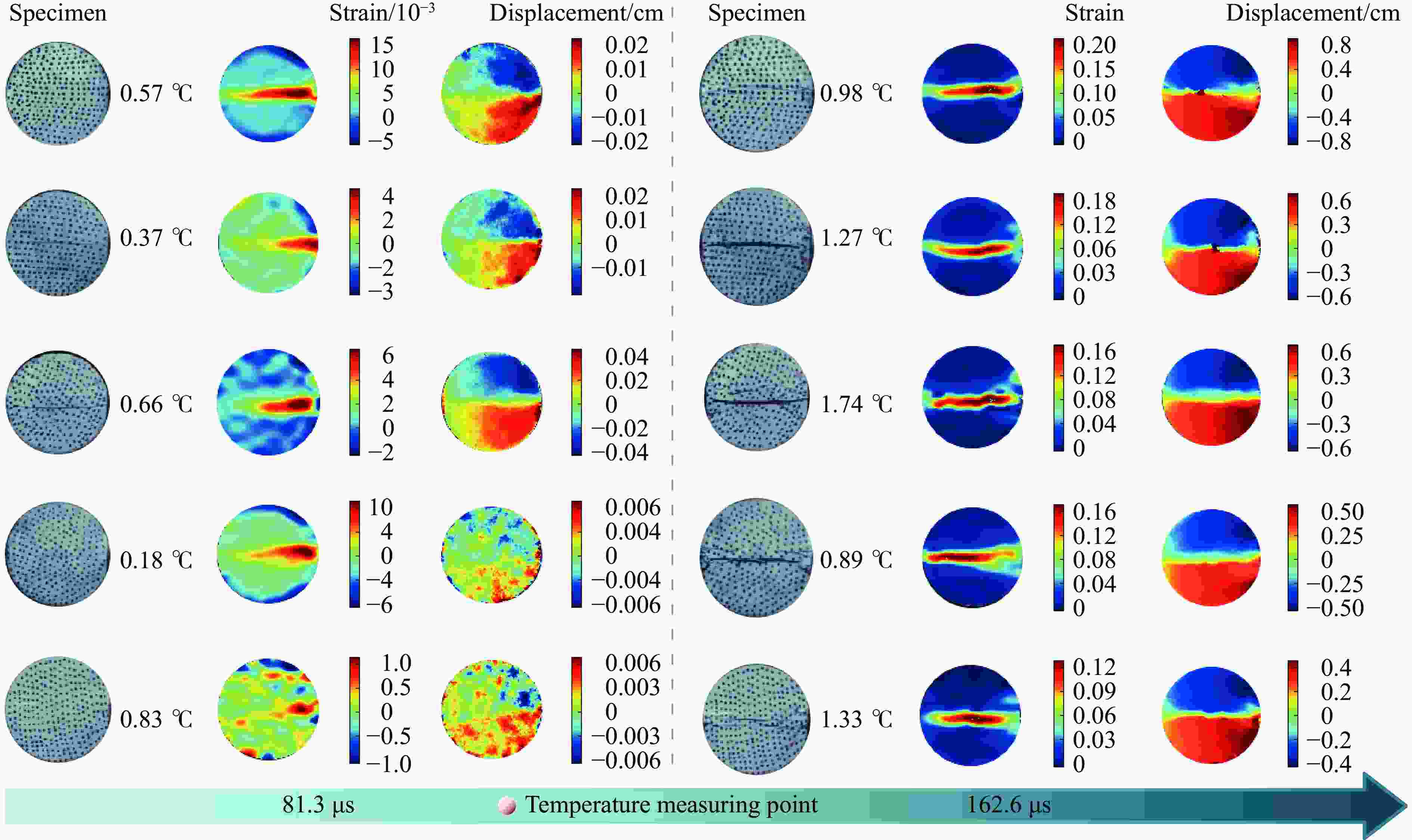

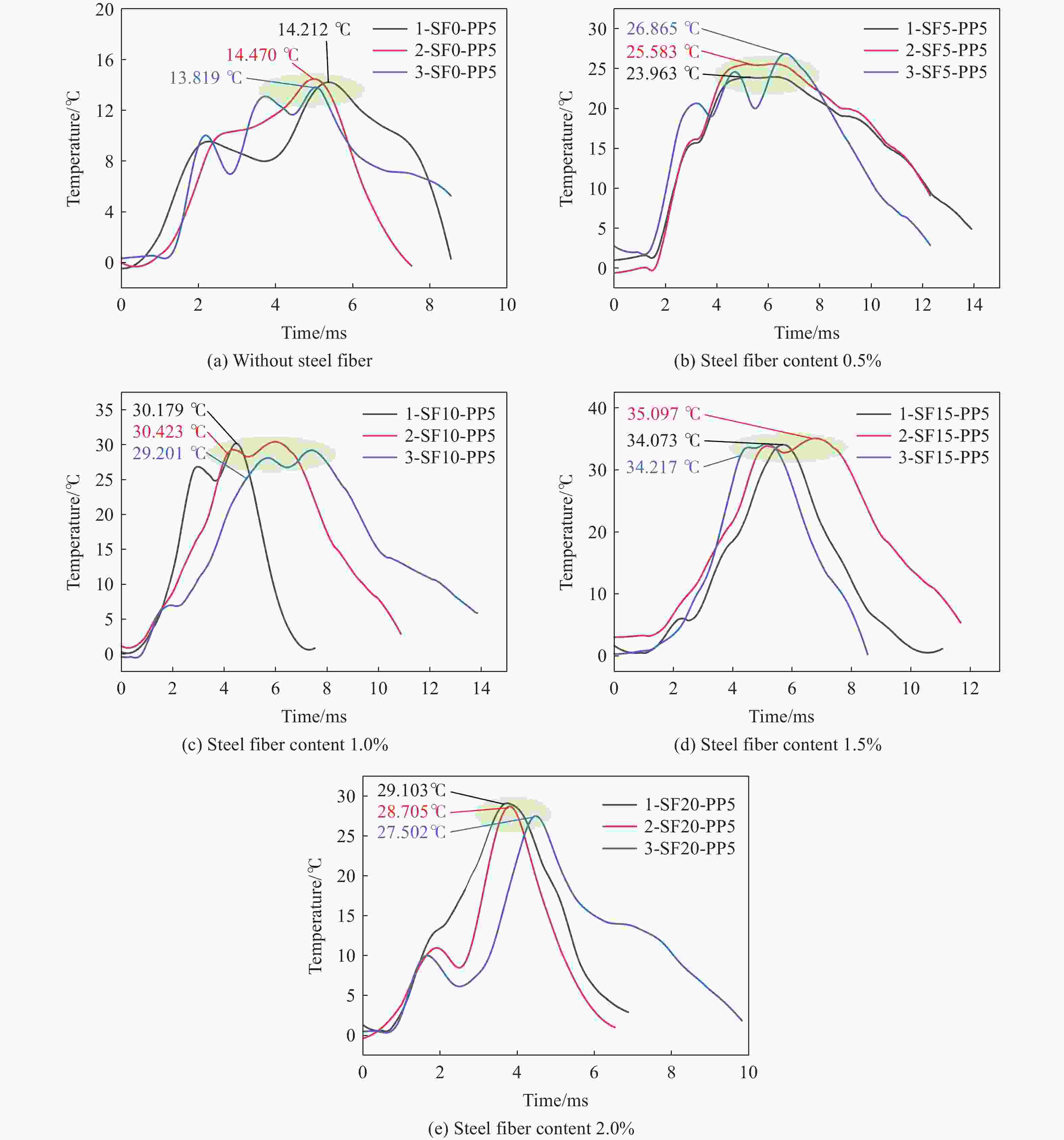

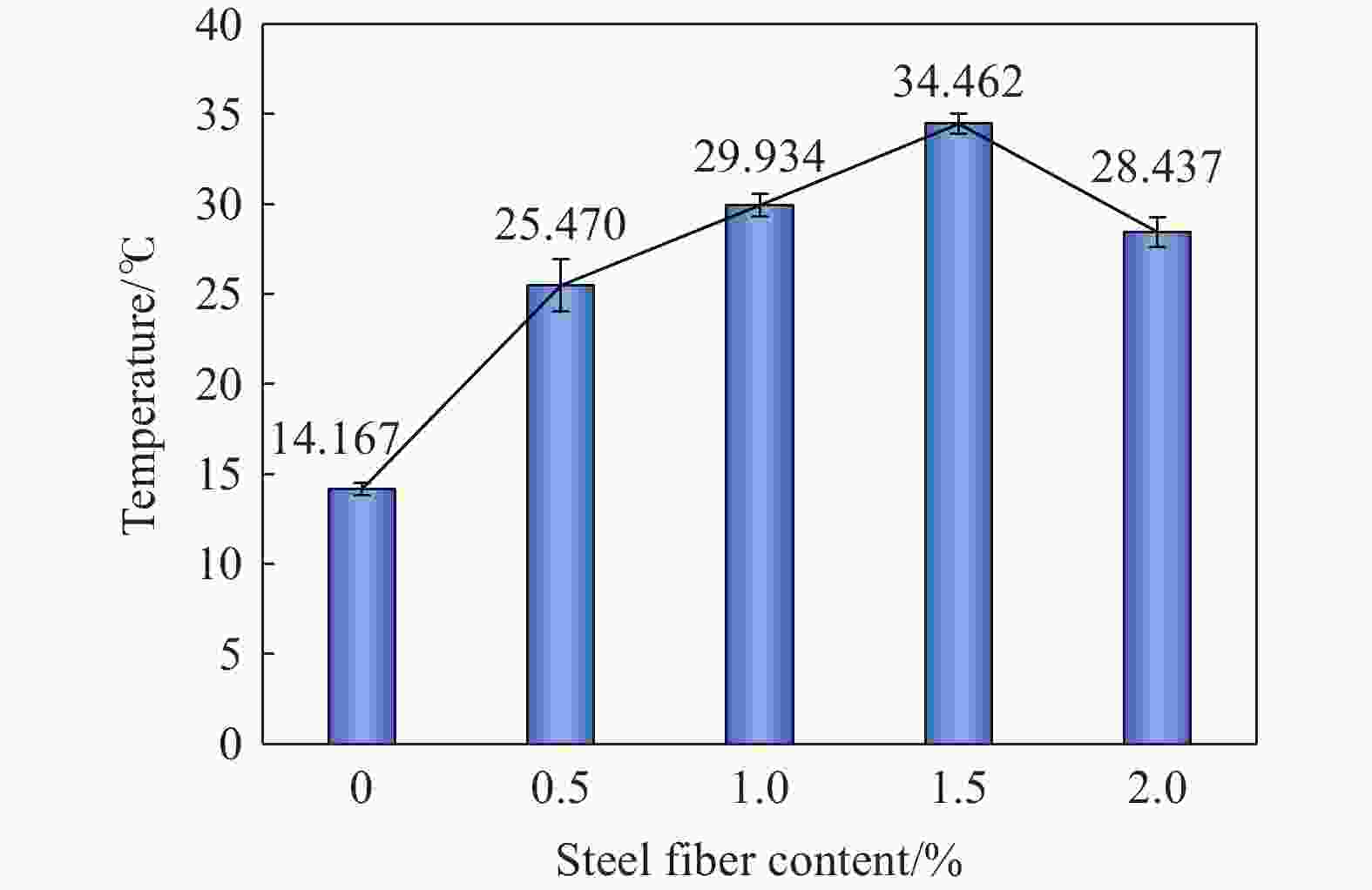

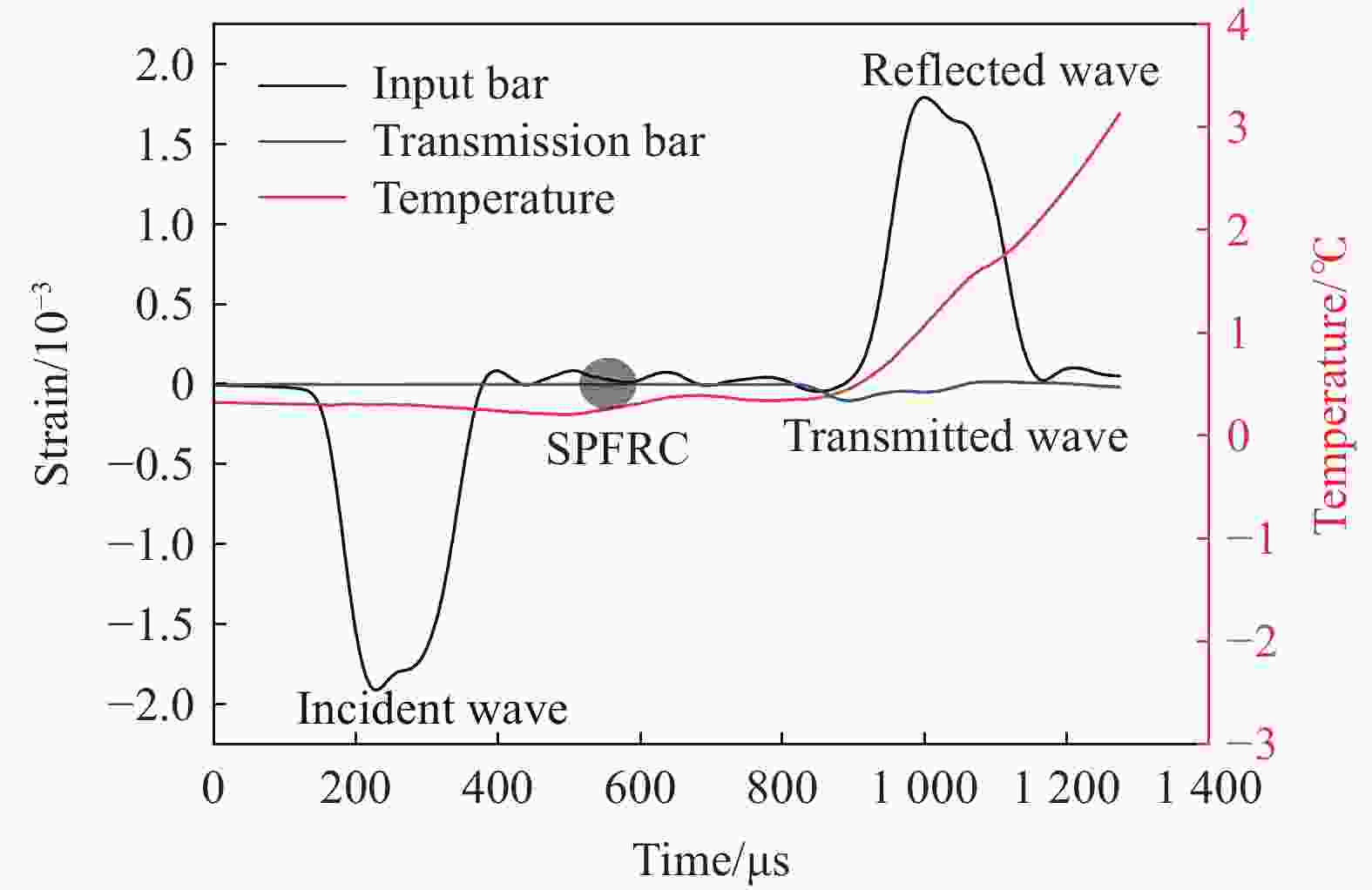

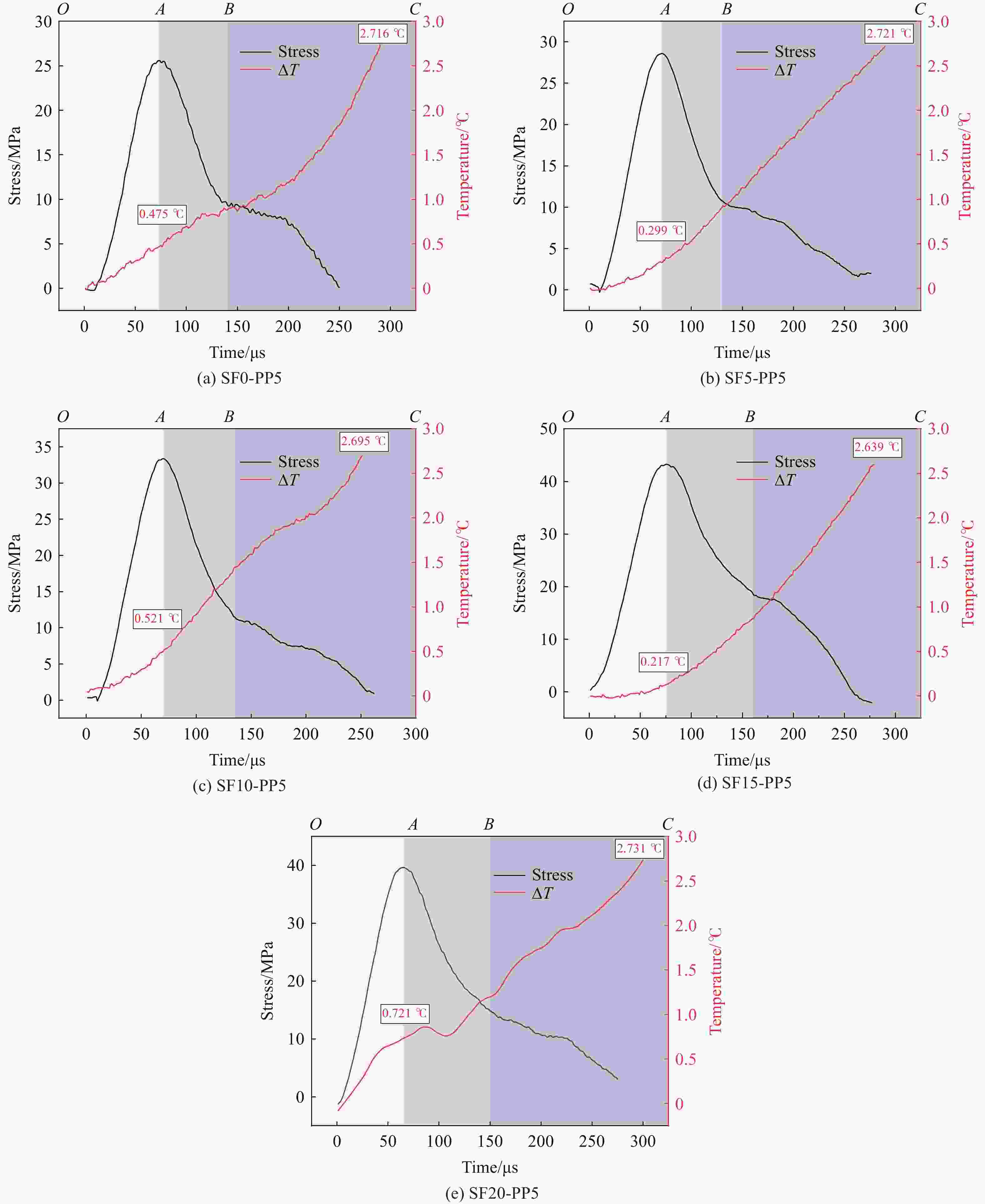

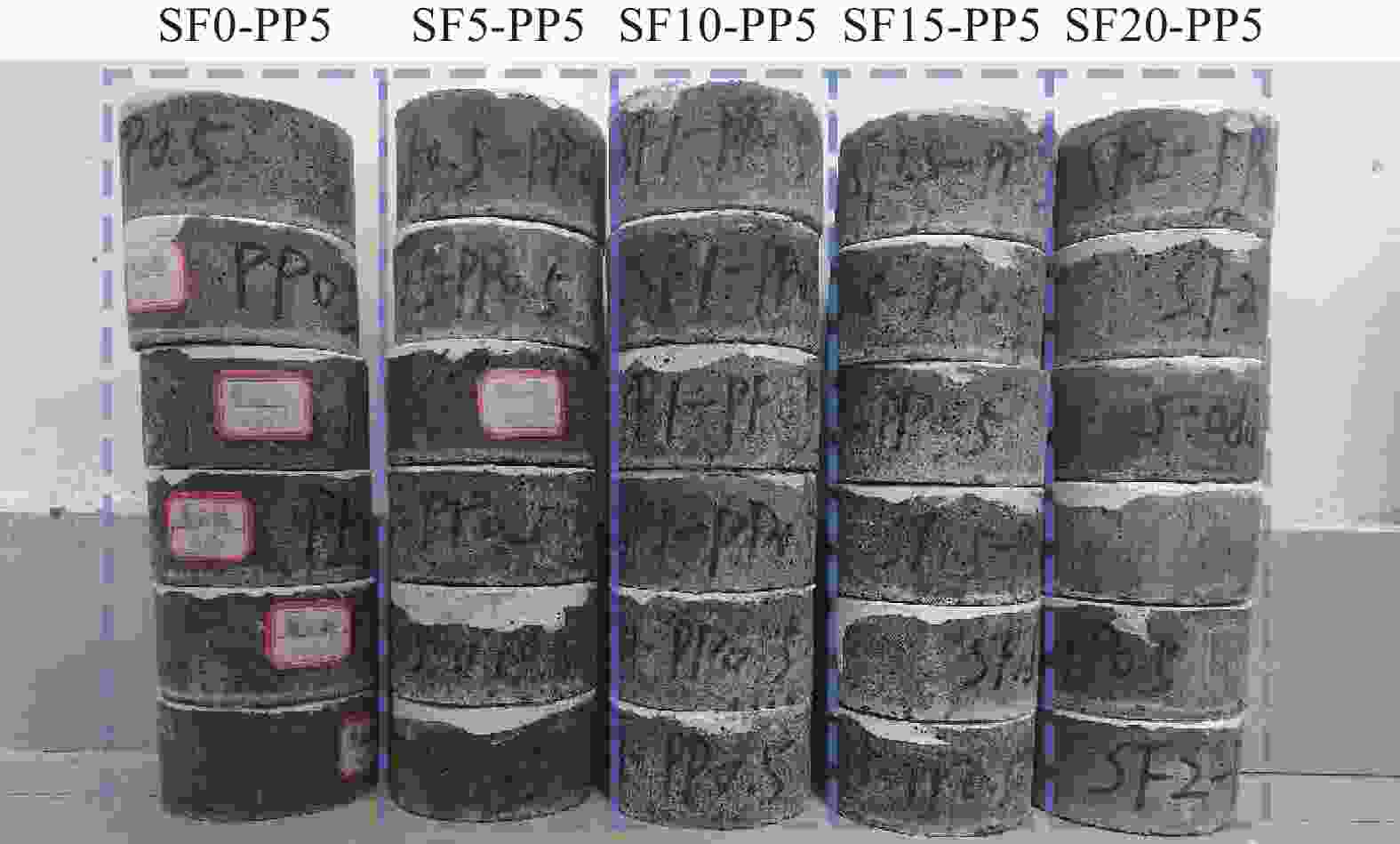

Abstract: In order to study the dynamic mechanical properties of concrete and the dynamic temperature at the crack under impact, steel-polypropylene fiber reinforced concrete (SPFRC) was taken as the research object using a self-built high-speed infrared temperature measurement system. The time resolution of the high-speed infrared temperature measurement system is in the order of microsecond. The concrete temperature curve was fitted by static calibration test as a reference. Combined with the Hopkinson pressure bar test device, the dynamic properties of SPFRC specimens with different steel fiber contents and the dynamic temperature change at the crack were studied. The results indicate a significant coupling effect between the temperature evolution and mechanical properties of the concrete specimens and substantial influences of the steel fiber content on both dynamic performance and temperature. Specifically, as the steel fiber content increases, the compressive strength of the concrete improves, reaching optimal mechanical performance at 1.5% steel fiber content. However, at 2.0% steel fiber content, the mechanical performance slightly decreases due to an increase in internal voids within the concrete. During impact, the dynamic temperature effect at the crack location exhibits a “stepped” pattern, with temperature change occurring in two distinct stages: an initial slow rise during early crack formation, followed by a sharp increase as friction and shear effects intensify with crack propagation. The influence of varying steel fiber content on temperature change is limited, with peak temperature and peak stress showing similar trends. The primary temperature variations are driven by crack propagation and frictional effects. After impact, the overall temperature in SPFRC specimens continues to rise within the first 300 μs. Due to the thermal lag, the temperature does not decrease immediately after unloading. The high-speed infrared temperature measurement system provides a new method for real-time monitoring of temperature changes at concrete crack locations, offering a basis for assessing temperature evolution at cracks and the evaluation of crack propagation behavior. -

表 1 纤维基本参数

Table 1. Basic property parameters of fiber

纤维 长度/

mm直径/

mm抗拉强度/

MPa弹性模量/

GPa密度/

(kg·m−3)镀铜钢纤维 15 0.25 2100 210 7.80×103 聚丙烯纤维 10 0.18 750 8 0.91×103 表 2 不同混杂比例的混凝土的配比

Table 2. The mixture design of concrete with different mixed proportions

混凝土

编号配比/(kg·m−3) 聚丙烯

纤维体积

掺量/%钢纤维

体积掺量/

%水泥 微硅粉 石英粉 细河沙 减水剂 水 SF0-PP5 800 200 240 880 14.4 152 0.5 0 SF5-PP5 800 200 240 880 14.4 152 0.5 0.5 SF10-PP5 800 200 240 880 14.4 152 0.5 1.0 SF15-PP5 800 200 240 880 14.4 152 0.5 1.5 SF20-PP5 800 200 240 880 14.4 152 0.5 2.0 表 3 SPFRC试件的动态巴西圆盘劈裂试验结果

Table 3. Dynamic Brazilian disc splitting test results of SPFRC specimens

组别 试验编号 钢纤维体积掺量/% 聚丙烯纤维体积掺量/% 速度/(m·s−1) 应变率/s−1 峰值应力/MPa 1 1-SF0-PP5 0 0.5 19.56 267.5 25.40 1-SF5-PP5 0.5 0.5 19.00 269.9 27.81 1-SF10-PP5 1.0 0.5 19.96 269.9 33.18 1-SF15-PP5 1.5 0.5 19.42 268.1 42.29 1-SF20-PP5 2.0 0.5 19.64 261.6 39.97 2 2-SF0-PP5 0 0.5 19.96 265.2 25.55 2-SF5-PP5 0.5 0.5 19.43 267.1 29.01 2-SF10-PP5 1.0 0.5 19.75 267.2 32.29 2-SF15-PP5 1.5 0.5 19.21 259.8 42.18 2-SF20-PP5 2.0 0.5 19.00 272.4 40.64 3 3-SF0-PP5 0 0.5 19.86 269.1 23.50 3-SF5-PP5 0.5 0.5 — 280.6 28.55 3-SF10-PP5 1.0 0.5 19.52 267.2 32.85 3-SF15-PP5 1.5 0.5 19.76 268.2 43.25 3-SF20-PP5 2.0 0.5 19.68 265.4 39.37 表 4 SPFRC试件的动态温度试验结果

Table 4. Dynamic temperature test results of SPFRC specimens

混凝土试件 钢纤维体积掺量/% 均值温度Ta/℃ 峰值温度Tm/℃ 峰值均值温度Tma/℃ 高温保持时间tc/ms 1-SF0-PP5 0 13.685 14.212 14.167 1.462 2-SF0-PP5 0 13.241 14.470 1.415 3-SF0-PP5 0 13.435 13.819 1.524 1-SF5-PP5 0.5 23.443 23.963 25.470 3.456 2-SF5-PP5 0.5 24.497 25.583 2.859 3-SF5-PP5 0.5 23.834 26.865 2.613 1-SF10-PP5 1.0 27.097 30.179 29.934 2.501 2-SF10-PP5 1.0 28.250 30.423 3.029 3-SF10-PP5 1.0 27.774 29.201 2.809 1-SF15-PP5 1.5 33.536 34.073 34.462 1.020 2-SF15-PP5 1.5 33.831 35.097 1.499 3-SF15-PP5 1.5 33.645 34.217 3.058 1-SF20-PP5 2.0 57.652 29.103 28.437 1.053 2-SF20-PP5 2.0 56.942 28.705 0.674 3-SF20-PP5 2.0 25.241 27.502 0.523 -

[1] RUIZ G, DE LA ROSA A, ALMEIDA L C, et al. Dynamic mixed-mode fracture in SCC reinforced with steel fibers: an experimental study [J]. International Journal of Impact Engineering, 2019, 129: 101–111. DOI: 10.1016/j.ijimpeng.2019.03.003. [2] TÜRKMEN İ, KANTARCI A. Effects of expanded perlite aggregate and different curing conditions on the physical and mechanical properties of self-compacting concrete [J]. Building and Environment, 2007, 42(6): 2378–2383. DOI: 10.1016/j.buildenv.2006.06.002. [3] FRAZÃO C, CAMÕES A, BARROS J, et al. Durability of steel fiber reinforced self-compacting concrete [J]. Construction and Building Materials, 2015, 80: 155–166. DOI: 10.1016/j.conbuildmat.2015.01.061. [4] SUESCUM-MORALES D, RÍOS J D, DE LA CONCHA A M, et al. Effect of moderate temperatures on compressive strength of ultra-high-performance concrete: a microstructural analysis [J]. Cement and Concrete Research, 2021, 140: 106303. DOI: 10.1016/j.cemconres.2020.106303. [5] DATCU S, IBOS L, CANDAU Y, et al. Improvement of building wall surface temperature measurements by infrared thermography [J]. Infrared Physics & Technology, 2005, 46(6): 451–467. DOI: 10.1016/j.infrared.2005.01.001. [6] RAMEZANIANPOUR A A, ESMAEILI M, GHAHARI S A, et al. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers [J]. Construction and Building Materials, 2013, 44: 411–418. DOI: 10.1016/j.conbuildmat.2013.02.076. [7] REN G S, GAO X J, ZHANG H Z. Utilization of hybrid sisal and steel fibers to improve elevated temperature resistance of ultra-high performance concrete [J]. Cement and Concrete Composites, 2022, 130: 104555. DOI: 10.1016/j.cemconcomp.2022.104555. [8] PARK J J, YOO D Y, KIM S, et al. Benefits of synthetic fibers on the residual mechanical performance of UHPFRC after exposure to ISO standard fire [J]. Cement and Concrete Composites, 2019, 104: 103401. DOI: 10.1016/j.cemconcomp.2019.103401. [9] KODUR V K R, CHENG F P, WANG T C, et al. Effect of strength and fiber reinforcement on fire resistance of high-strength concrete columns [J]. Journal of Structural Engineering, 2003, 129(2): 253–259. DOI: 10.1061/(ASCE)0733-9445(2003)129:2(253). [10] XU L H, DENG F Q, CHI Y. Nano-mechanical behavior of the interfacial transition zone between steel-polypropylene fiber and cement paste [J]. Construction and Building Materials, 2017, 145: 619–638. DOI: 10.1016/j.conbuildmat.2017.04.035. [11] 徐礼华, 邓方茜, 徐浩然, 等. 钢-聚丙烯混杂纤维混凝土柱抗震性能试验研究 [J]. 土木工程学报, 2016, 49(1): 3–13. DOI: 10.15951/j.tmgcxb.2016.01.002.XU L H, DENG F Q, XU H R, et al. On seismic behavior of steel-polypropylene hybrid fiber reinforced concrete columns [J]. China Civil Engineering Journal, 2016, 49(1): 3–13. DOI: 10.15951/j.tmgcxb.2016.01.002. [12] 王秋维, 梁林, 史庆轩. 混杂钢纤维超高性能混凝土轴拉力学性能及本构模型 [J]. 复合材料学报, 2024, 41(1): 383–394. DOI: 10.13801/j.cnki.fhclxb.20230529.002.WANG Q W, LIANG L, SHI Q X. Mechanical properties and constitutive model of ultra-high performance concrete with hybrid steel fiber under axial tension [J]. Acta Materiae Compositae Sinica, 2024, 41(1): 383–394. DOI: 10.13801/j.cnki.fhclxb.20230529.002. [13] WANG Z H, BAI E L, LIANG L, et al. Effect of ceramic fiber on mechanical properties of concrete with different strength grades and its strengthening and toughening behaviors under impact load [J]. Construction and Building Materials, 2023, 402: 132993. DOI: 10.1016/j.conbuildmat.2023.132993. [14] 张超峰, 管仲国. 混凝土结构冲击的研究现状 [C]//第五届土木工程国际会议论文集. 南京, 2022. DOI: 10.11648/j.sd.20210904.21.ZHANG C F, GUAN Z G. Research status of impact on concrete structures [C]//5th International Conference on Civil Engineering. Nanjing, 2022. DOI: 10.11648/j.sd.20210904.21. [15] LI B, CHI Y, XU L H, et al. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete [J]. Construction and Building Materials, 2018, 191: 80–94. DOI: 10.1016/j.conbuildmat.2018.09.202. [16] ZHOU X, XIE Y J, LONG G C, et al. Effect of surface characteristics of aggregates on the compressive damage of high-strength concrete based on 3D discrete element method [J]. Construction and Building Materials, 2021, 301: 124101. DOI: 10.1016/j.conbuildmat.2021.124101. [17] YU Y, ZHENG Y, ZHAO X Y. Mesoscale modeling of recycled aggregate concrete under uniaxial compression and tension using discrete element method [J]. Construction and Building Materials, 2021, 268: 121116. DOI: 10.1016/j.conbuildmat.2020.121116. [18] CAO K W, DONG F R, YU Y H, et al. Infrared radiation response mechanism of sandstone during loading and fracture process [J]. Theoretical and Applied Fracture Mechanics, 2023, 126: 103974. DOI: 10.1016/j.tafmec.2023.103974. [19] LI X L, LI Z H, YIN S, et al. Experimental study on infrared thermal response characteristics of water-bearing concrete under drop hammer impact [J]. Infrared Physics & Technology, 2023, 135: 104899. DOI: 10.1016/j.infrared.2023.104899. [20] 吴立新, 李国华, 吴焕萍. 热红外成像用于固体撞击瞬态过程监测的实验探索 [J]. 科学通报, 2001, 46(2): 172–176. DOI: 10.1360/csb2001-46-2-172.WU L X, WU H P, LI G H. Experimental exploration to thermal infrared imaging for detecting the transient process of solid impact [J]. Chinese Scientific Bulletin, 2001, 46(10): 872–877. DOI: 10.1007/BF02900442. [21] 张宗贤, 喻勇, 赵清. 岩石断裂韧度的温度效应 [J]. 中国有色金属学报, 1994, 4(2): 7–11. DOI: 10.19476/j.ysxb.1004.0609.1994.02.003. [22] 张志镇, 高峰, 刘治军. 温度影响下花岗岩冲击倾向及其微细观机制研究 [J]. 岩石力学与工程学报, 2010, 29(8): 1591–1602.ZHANG Z Z, GAO F, LIU Z J. Research on rockburst proneness and its microcosmic mechanism of granite considering temperature effect [J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(8): 1591–1602. [23] ALGOURDIN N, PLIYA P, BEAUCOUR A L, et al. Effect of fine and coarse recycled aggregates on high-temperature behaviour and residual properties of concrete [J]. Construction and Building Materials, 2022, 341: 127847. DOI: 10.1016/j.conbuildmat.2022.127847. [24] HIASA S, BIRGUL R, NECATI CATBAS F. A data processing methodology for infrared thermography images of concrete bridges [J]. Computers & Structures, 2017, 190: 205–218. DOI: 10.1016/j.compstruc.2017.05.011. [25] YIN S, LI Z H, SONG D Z, et al. Experimental study on the infrared precursor characteristics of gas-bearing coal failure under loading [J]. International Journal of Mining Science and Technology, 2021, 31(5): 901–912. DOI: 10.1016/j.ijmst.2021.07.003. [26] GAO Q Q, MA L Q, LIU W, et al. Research on the denoising method of infrared thermogram during rock fracture [J]. Infrared Physics & Technology, 2023, 131: 104651. DOI: 10.1016/j.infrared.2023.104651. [27] ICHI E, DORAFSHAN S. Effectiveness of infrared thermography for delamination detection in reinforced concrete bridge decks [J]. Automation in Construction, 2022, 142: 104523. DOI: 10.1016/j.autcon.2022.104523. [28] YIN S, LI Z H, WANG E Y, et al. The infrared thermal effect of coal failure with different impact types and its relationship with bursting liability [J]. Infrared Physics & Technology, 2024, 138: 105263. DOI: 10.1016/j.infrared.2024.105263. [29] 吴立新, 钟声, 吴育华, 等. 落球撞击岩石热红外辐射温度的时延特征 [J]. 中国矿业大学学报, 2005, 34(5): 557–563. DOI: 10.3321/j.issn:1000-1964.2005.05.004.WU L X, ZHONG S, WU Y H, et al. Time dependent features of thermal infrared radiation temperature of rock impacted by free-falling steel ball [J]. Journal of China University of Mining & Technology, 2005, 34(5): 557–563. DOI: 10.3321/j.issn:1000-1964.2005.05.004. [30] 吴立新, 吴育华, 钟声, 等. 岩石撞击的热红外成像探测研究进展与方向 [J]. 岩石力学与工程学报, 2006, 25(11): 2180–2186. DOI: 10.3321/j.issn:1000-6915.2006.11.003.WU L X, WU Y H, ZHONG S, et al. Research progresses and directions of detection on rock impaction with thermal infrared imaging [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(11): 2180–2186. DOI: 10.3321/j.issn:1000-6915.2006.11.003. [31] 刘善军, 吴立新, 张艳博. 岩石破裂前红外热像的时空演化特征 [J]. 东北大学学报(自然科学版), 2009, 30(7): 1034–1038. DOI: 10.3969/j.issn.1005-3026.2009.07.029.LIU S J, WU L X, ZHANG Y B. Temporal-spatial evolution features of infrared thermal images before rock failure [J]. Journal of Northeastern University (Natural Science), 2009, 30(7): 1034–1038. DOI: 10.3969/j.issn.1005-3026.2009.07.029. [32] 邓志毅, 张东胜, 安里千. 热探测法监测岩石应力变化的实验研究 [J]. 中国矿业大学学报, 2006, 35(5): 623–627. DOI: 10.3321/j.issn:1000-1964.2006.05.012.DENG Z Y, ZHANG D S, AN L Q. Experimental of monitoring stress variation of rock using a thermal detection [J]. Journal of China University of Mining & Technology, 2006, 35(5): 623–627. DOI: 10.3321/j.issn:1000-1964.2006.05.012. [33] SUN X M, XU H C, HE M C, et al. Experimental investigation of the occurrence of rockburst in a rock specimen through infrared thermography and acoustic emission [J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 93: 250–259. DOI: 10.1016/j.ijrmms.2017.02.005. [34] LOU Q, HE X Q. Experimental study on infrared radiation temperature field of concrete under uniaxial compression [J]. Infrared Physics & Technology, 2018, 90: 20–30. DOI: 10.1016/j.infrared.2018.01.033. [35] 周子龙, 刘洋, 蔡鑫, 等. 冲击荷载下砂岩的红外辐射特性 [J]. 中南大学学报(自然科学版), 2022, 53(7): 2555–2562. DOI: 10.11817/j.issn.1672-7207.2022.07.015.ZHOU Z L, LIU Y, CAI X, et al. Infrared radiation characteristics of sandstone exposed to impact loading [J]. Journal of Central South University (Science and Technology), 2022, 53(7): 2555–2562. DOI: 10.11817/j.issn.1672-7207.2022.07.015. [36] TIAN H, LI Z H, YIN S, et al. Research on infrared radiation response and energy dissipation characteristics of sandstone crushing under impact load [J]. Engineering Geology, 2023, 322: 107171. DOI: 10.1016/j.enggeo.2023.107171. [37] CHEN H Y, CHEN C. Determining the emissivity and temperature of building materials by infrared thermometer [J]. Construction and Building Materials, 2016, 126: 130–137. DOI: 10.1016/j.conbuildmat.2016.09.027. [38] PEDRAM M, TAYLOR S, HAMILL G, et al. Experimental evaluation of heat transition mechanism in concrete with subsurface defects using infrared thermography [J]. Construction and Building Materials, 2022, 360: 129531. DOI: 10.1016/j.conbuildmat.2022.129531. [39] HODOWANY J. On the conversion of plastic work into heat [M]. California: California Institute of Technology, 1997: 44–49. [40] MASON J J, ROSAKIS A J, RAVICHANDRAN G. On the strain and strain rate dependence of the fraction of plastic work converted to heat: an experimental study using high speed infrared detectors and the Kolsky bar [J]. Mechanics of Materials, 1994, 17(2/3): 135–145. DOI: 10.1016/0167-6636(94)90054-X. [41] POTDAR Y K, ZEHNDER A T. Measurements and simulations of temperature and deformation fields in transient metal cutting [J]. Journal of Manufacturing Science and Engineering, 2003, 125(4): 645–655. DOI: 10.1115/1.1596571. [42] NIETO-FUENTES J C, OSOVSKI S, RITTEL D. High-speed infrared thermal measurements of impacted metallic solids [J]. MethodsX, 2020, 7: 100914. DOI: 10.1016/j.mex.2020.100914. [43] 夏源明, 饶世国, 杨报昌. 红外瞬态测温装置及其在冲击拉伸试验中的应用 [J]. 实验力学, 1990, 5(2): 170–177.XIA Y M, RAO S G, YANG B C. An infrared transient temperature measuring apparatus and its application to the tensile impact testing [J]. Journal of Experimental Mechanics, 1990, 5(2): 170–177. [44] 刘永贵, 唐志平, 崔世堂. 冲击载荷下瞬态温度的实时测量方法 [J]. 爆炸与冲击, 2014, 34(4): 471–475. DOI: 10.11883/1001-1455(2014)04-0471-05.LIU Y G, TANG Z P, CUI S T. Real-time measuring methods for transient temperature under shock loading [J]. Explosion and Shock Waves, 2014, 34(4): 471–475. DOI: 10.11883/1001-1455(2014)04-0471-05. [45] ZHANG T, GUO Z R, YUAN F P, et al. Investigation on the plastic work-heat conversion coefficient of 7075-T651 aluminum alloy during an impact process based on infrared temperature measurement technology [J] Acta Mechanica Sinica, 2018, 34(2): 327–333. DOI: 10.1007/s10409-017-0673-8. [46] R. D. 小哈德逊. 红外系统原理 [M]. 北京: 国防工业出版社, 1975.HUDSON R D JR. Infrared systen engineering [M]. Beijing: National Defense Industry Press, 1975. [47] 晏敏, 颜永红, 曾云, 等. 非接触式红外测温原理及误差分析 [J]. 计量技术, 2005(1): 23–25. DOI: 10.3969/j.issn.1000-0771.2005.01.009. [48] ZEHNDER A T, GUDURU P R, ROSAKIS A J, et al. Million frames per second infrared imaging system [J]. Review of Scientific Instruments, 2000, 71(10): 3762–3768. DOI: 10.1063/1.1310350. [49] 宋力, 胡时胜. SHPB数据处理中的二波法与三波法 [J]. 爆炸与冲击, 2005, 25(4): 368–373. DOI: 10.3321/j.issn:1001-1455.2005.04.014.SONG L, HU S S. Two-wave and three-wave method in SHPB data processing [J]. Explosion and Shock Waves, 2005, 25(4): 368–373. DOI: 10.3321/j.issn:1001-1455.2005.04.014. [50] 赵毅鑫, 肖汉, 黄亚琼. 霍普金森杆冲击加载煤样巴西圆盘劈裂试验研究 [J]. 煤炭学报, 2014, 39(2): 286–291. DOI: 10.13225/j.cnki.jccs.2013.2011.ZHAO Y X, XIAO H, HUANG Y Q. Dynamic split tensile test of Brazilian disc of coal with split Hopkinson pressure bar loading [J]. Journal of China Coal Society, 2014, 39(2): 286–291. DOI: 10.13225/j.cnki.jccs.2013.2011. [51] LI J H, YANG L Y, XIE H Z, et al. Research on impact toughness and crack propagation of basalt fiber reinforced concrete under SHPB splitting test [J]. Journal of Building Engineering, 2023, 77: 107445. DOI: 10.1016/j.jobe.2023.107445. [52] PHAM T M, LIU J L, TRAN P, et al. Dynamic compressive properties of lightweight rubberized geopolymer concrete [J]. Construction and Building Materials, 2020, 265: 120753. DOI: 10.1016/j.conbuildmat.2020.120753. [53] HUANG B F, XIAO Y. Compressive impact tests of lightweight concrete with 155-mm-diameter spilt Hopkinson pressure bar [J]. Cement and Concrete Composites, 2020, 114: 103816. DOI: 10.1016/j.cemconcomp.2020.103816. [54] BAO X H, LI Y P, CHEN X S, et al. Investigation on the flexural behaviour and crack propagation of hybrid steel fibre reinforced concrete with a low fibre content for tunnel structures [J]. Construction and Building Materials, 2024, 417: 135253. DOI: 10.1016/j.conbuildmat.2024.135253. [55] LI B, CHEN Z K, WANG S N, et al. A review on the damage behavior and constitutive model of fiber reinforced concrete at ambient temperature [J]. Construction and Building Materials, 2024, 412: 134919. DOI: 10.1016/j.conbuildmat.2024.134919. -

下载:

下载: